Method for preparing anti-aging wearing-resistant heat-shrinkable tubing

A heat-shrinkable sleeve and anti-aging technology, which is applied in the field of preparation of anti-aging and wear-resistant heat-shrinkable sleeves, can solve the problems of reducing the protective and marking functions of heat-shrinkable sleeves, shortening the service life of heat-shrinkable sleeves, aging resistance and durability Improve cross-linking stability, practicality enhancement, high strength and corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

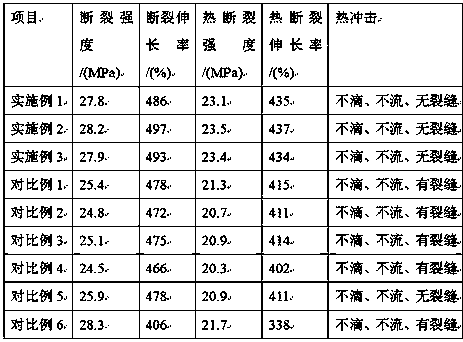

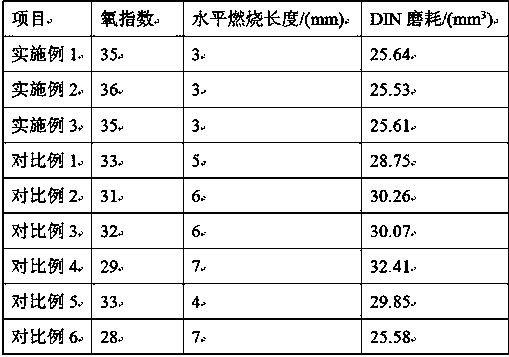

Examples

Embodiment 1

[0020] A method for preparing an anti-aging wear-resistant heat-shrinkable sleeve, comprising the following steps:

[0021] (1) Raw material modification: put polyethylene terephthalate in the reaction kettle, heat slowly until it is completely melted, the heating rate is 2°C / min, keep it warm for 15 minutes, add polypropylene glycol into the reaction kettle, the amount added 2.1% of the polyethylene terephthalate weight, continue to insulate and stir for 70 minutes, promote the sufficient mixing and grafting of polyethylene terephthalate and polypropylene glycol, and carry out polyethylene terephthalate modification, so that the obtained modified polyethylene terephthalate has higher strength and corrosion resistance, and obtains modified polyethylene terephthalate;

[0022] (2) Mixed colloid: Add styrene-butadiene rubber and amino silicone oil to the modified polyethylene terephthalate. The amount of styrene-butadiene rubber added is 7% of the weight of the modified polyethy...

Embodiment 2

[0027] A method for preparing an anti-aging wear-resistant heat-shrinkable sleeve, comprising the following steps:

[0028] (1) Raw material modification: put polyethylene terephthalate in the reaction kettle, heat slowly until it melts completely, the heating rate is 2.5°C / min, keep it warm for 18 minutes, add polypropylene glycol into the reaction kettle, the amount added 2.2% of the polyethylene terephthalate weight, continue to insulate and stir for 80 minutes, promote the sufficient mixing and grafting of polyethylene terephthalate and polypropylene glycol, and carry out polyethylene terephthalate modification, so that the obtained modified polyethylene terephthalate has higher strength and corrosion resistance, and obtains modified polyethylene terephthalate;

[0029] (2) Mixed colloid: add styrene-butadiene rubber and amino silicone oil to the modified polyethylene terephthalate, the amount of styrene-butadiene rubber added is 8% of the weight of the modified polyethyle...

Embodiment 3

[0034] A method for preparing an anti-aging wear-resistant heat-shrinkable sleeve, comprising the following steps:

[0035] (1) Raw material modification: put polyethylene terephthalate in the reaction kettle, heat slowly until it is completely melted, the heating rate is 3°C / min, keep warm for 20min, add polypropylene glycol into the reaction kettle, the amount added 2.3% of the weight of polyethylene terephthalate, continue to insulate and stir for 90min, promote polyethylene terephthalate and polypropylene glycol to fully mix and graft, and carry out polyethylene terephthalate modification, so that the obtained modified polyethylene terephthalate has higher strength and corrosion resistance, and obtains modified polyethylene terephthalate;

[0036](2) Mixed colloid: add styrene-butadiene rubber and amino silicone oil to the modified polyethylene terephthalate, the amount of styrene-butadiene rubber added is 9% of the weight of the modified polyethylene terephthalate, The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com