Processing method for enhancing skin quality of vegetable fish skin crisps

A processing method and skin technology, applied in the direction of food science, etc., can solve the problems of insufficient elasticity, low gel strength, and easy fading of vegetable and fish skins, so as to improve water retention and antifreeze effects, improve elasticity and gel Strength, improving the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

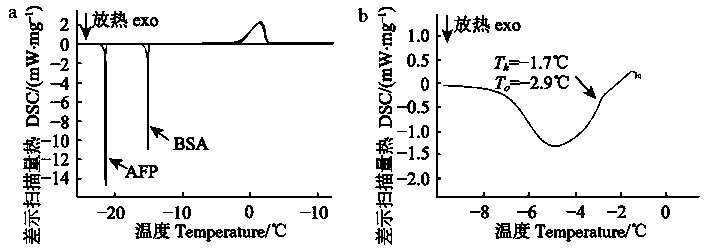

Image

Examples

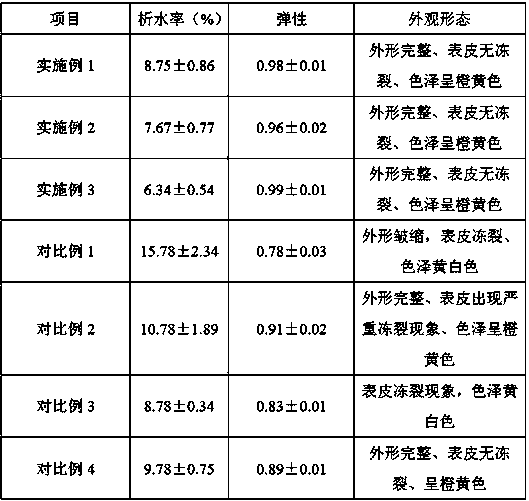

Embodiment 1

[0019] 1) Weigh 55 parts by weight of surimi, 5 parts by weight of carrot juice, 5 parts by weight of starch, 1 part by weight of curdlan gum, 0.5 parts by weight of xanthan gum, 2 parts by weight of enzymatic hydrolyzed solution of gold thread fish skin, 2.5 parts by weight of table salt, 2 parts by weight of white sugar and 27 parts by weight of water;

[0020] 2) Put the surimi in a high-speed vacuum chopping machine, add salt, and chop at a speed of 1800r / min for 7 minutes;

[0021] 3) After adding carrot juice and white sugar to the surimi slurry obtained in step (1), stir at a speed of 2100 r / min for 3 minutes;

[0022] 4) Add gold thread fish skin enzymatic hydrolysis solution, curdlan gum, xanthan gum and starch into the water in advance, stir magnetically for 30 minutes to make it evenly mixed, then add it to the vegetable surimi slurry obtained in step 2) to Stir at a speed of 1600 r / min for 8 minutes to obtain a skin slurry, which is pressed into a skin by a roller...

Embodiment 2

[0026] 1) Weigh 55 parts by weight of surimi, 5 parts by weight of carrot juice, 5 parts by weight of starch, 1 part by weight of curdlan gum, 1 part by weight of xanthan gum, 2 parts by weight of enzymatic hydrolyzate of gold wire fish skin, 2.5 parts by weight of table salt, 2 parts by weight of white sugar and 26.5 parts by weight of water;

[0027] 2) Put the surimi in a high-speed vacuum chopping machine, add salt, and chop at a speed of 2100r / min for 3 minutes;

[0028] 3) After adding carrot juice and white sugar to the surimi slurry obtained in step (1), stir at a speed of 2100 r / min for 3 minutes;

[0029] 4) Add gold thread fish skin enzymatic hydrolysis solution, curdlan gum, xanthan gum and starch into the water in advance, stir magnetically for 50 minutes to make it evenly mixed, then add it to the vegetable surimi slurry obtained in step 2) to Stir at a speed of 1800 r / min for 10 minutes to obtain a skin slurry, which is pressed into a skin by a roller-type nood...

Embodiment 3

[0033] 1) Weigh 55 parts by weight of surimi, 5 parts by weight of carrot juice, 5 parts by weight of starch, 1 part by weight of curdlan gum, 1 part by weight of xanthan gum, 3 parts by weight of enzymatic hydrolyzate of gold wire fish skin, 2.5 parts by weight of table salt, 2 parts by weight of white sugar and 25.5 parts by weight of water;

[0034] 2) Put the surimi in a high-speed vacuum chopping machine, add salt, and chop at a speed of 2100r / min for 3 minutes;

[0035] 3) After adding carrot juice and white sugar to the surimi slurry obtained in step (1), stir at a speed of 2100 r / min for 3 minutes;

[0036] 4) Add gold thread fish skin enzymatic hydrolysis solution, curdlan gum, xanthan gum and starch into the water in advance, stir magnetically for 50 minutes to make it evenly mixed, then add it to the vegetable surimi slurry obtained in step 2) to Stir at a speed of 1800 r / min for 10 minutes to obtain a skin slurry, which is pressed into a skin by a roller-type nood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com