Biogas slurry concentration method based on membrane separation

A membrane separation and biogas slurry technology, which is applied in the field of biogas slurry concentration based on membrane separation, can solve the problems of large amount of chemical agents, high concentration cost, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

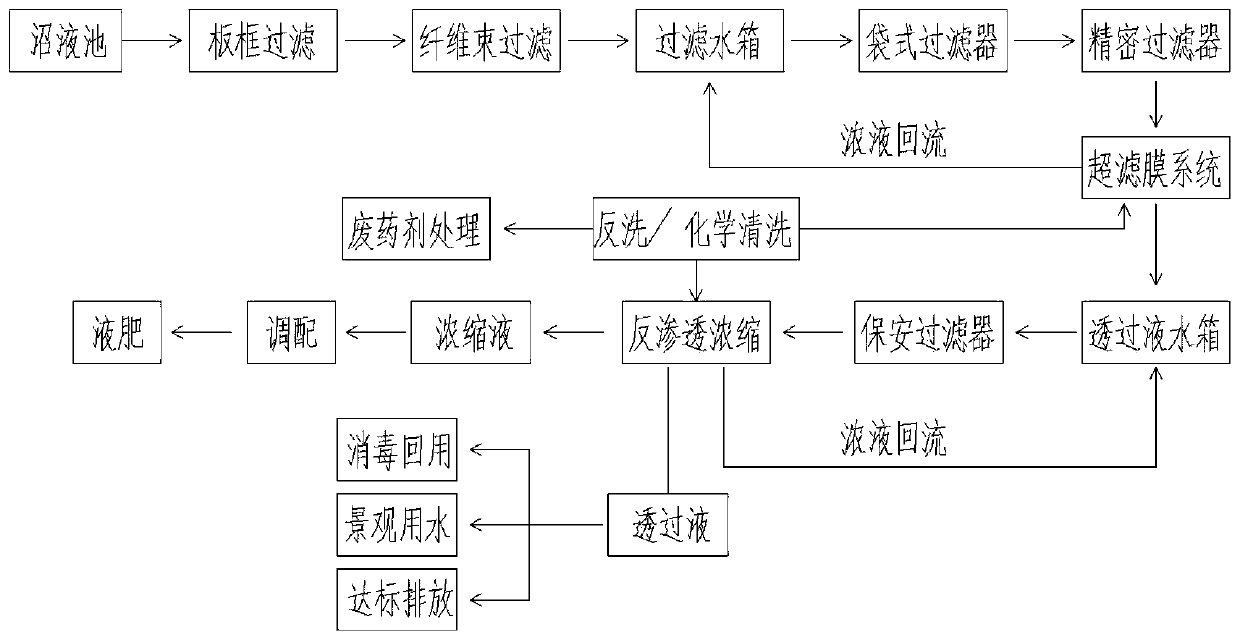

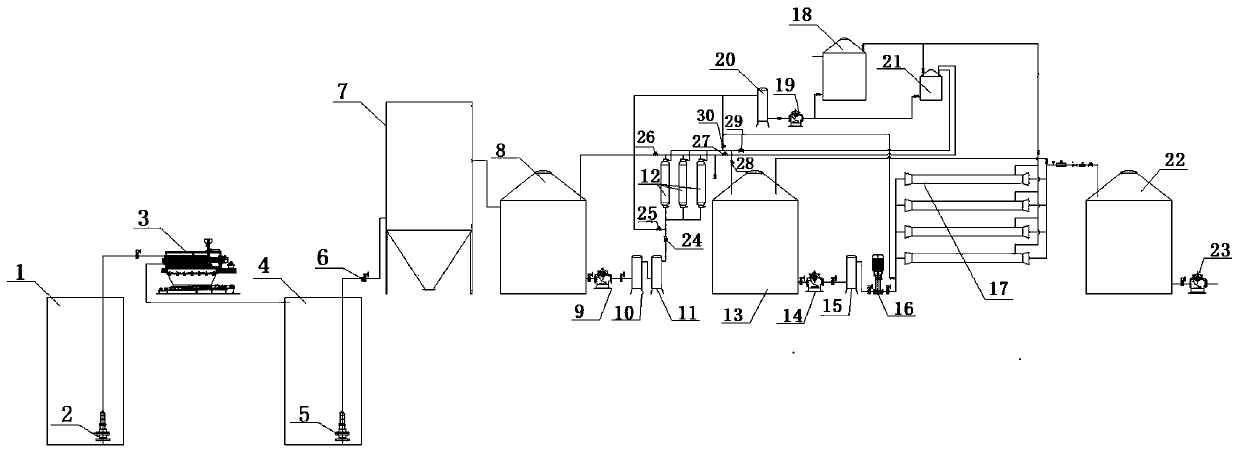

[0064] In the following, the biogas slurry concentration method based on membrane separation described in this technical solution will be described with a preferred embodiment. The biogas slurry concentration method as a preferred embodiment mainly includes the following steps:

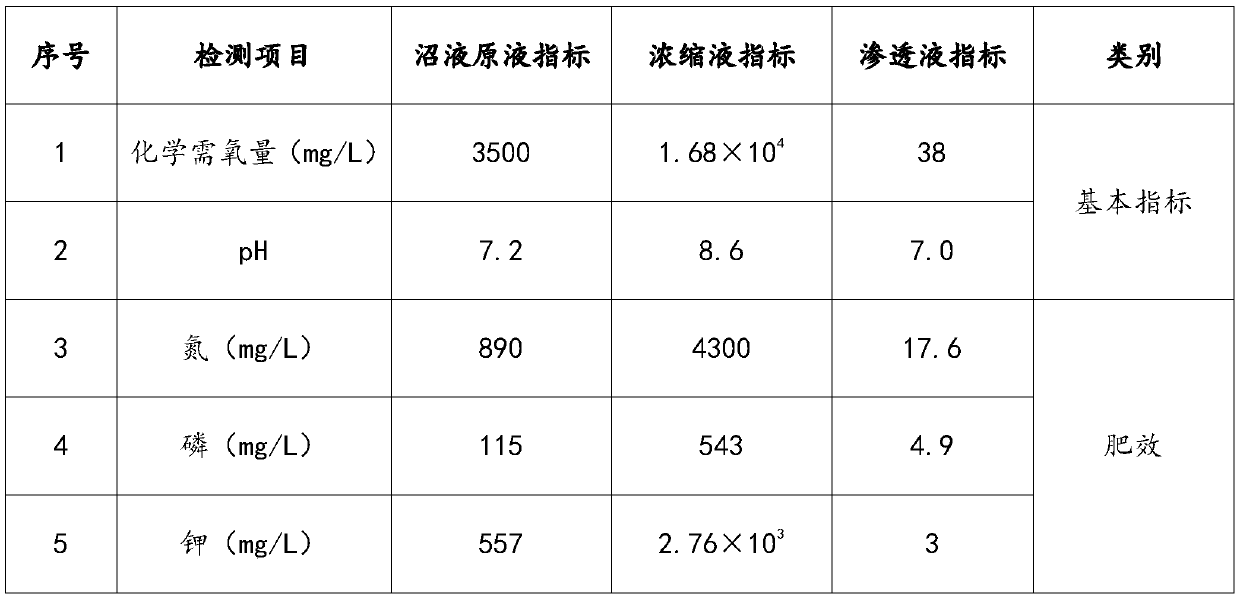

[0065] (1) Biogas slurry collection: the biogas slurry fermented by anaerobic fermentation tank is discharged to the biogas slurry tank, wherein the chemical oxygen demand (COD) in the biogas slurry after anaerobic fermentation is 3000-5000mg / L, and the ammonia nitrogen element The content is 900-1200mg / L. The fermented biogas slurry naturally settles in the biogas slurry tank to initially remove the biogas residue and other particulate matter carried by the biogas slurry, and then complete the concentration of organic matter, ammonia nitrogen (nitrogen element) and other nutrients.

[0066] (2) Biogas slurry pretreatment: the biogas slurry in the biogas slurry tank is transported to the plate and fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com