Explosion-proof polyurea material and preparation method thereof

A polyurea and prepolymer technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of fast curing reaction speed, high viscosity and large volume, and achieve slow reaction speed, low viscosity and low viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

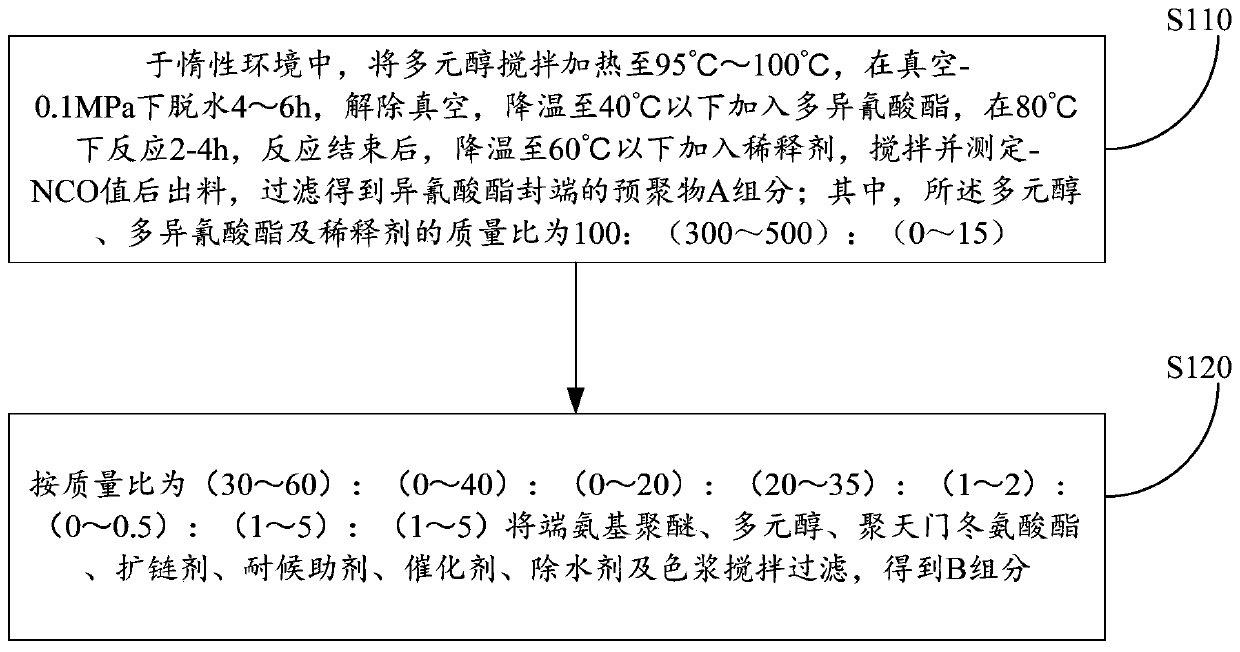

[0027] see figure 1 , the preparation method of a kind of explosion-proof polyurea material provided by the present invention, comprises the following steps:

[0028] Step S110: In an inert environment, stir and heat the polyol to 95°C-100°C, dehydrate it under vacuum -0.1MPa for 4-6 hours, release the vacuum, lower the temperature to below 40°C, add polyisocyanate, and react at 80°C for 2- 4h, after the reaction is over, cool down to below 60°C and add diluent, stir and measure the -NCO value, then discharge, and filter to obtain component A of the isocyanate-terminated prepolymer; wherein, the polyol, polyisocyanate and diluent The mass ratio is 100:(300~500):(0~15);

[0029] Step S120: According to the mass ratio (30-60): (0-40): (0-20): (20-35): (1-2): (0-0.5): (1-5): ( 1-5) Stir and filter the amino-terminated polyether, polyol, polyaspartate, chain extender, weather resistance additive, catalyst, water remover and color paste to obtain component B;

[0030] The volume...

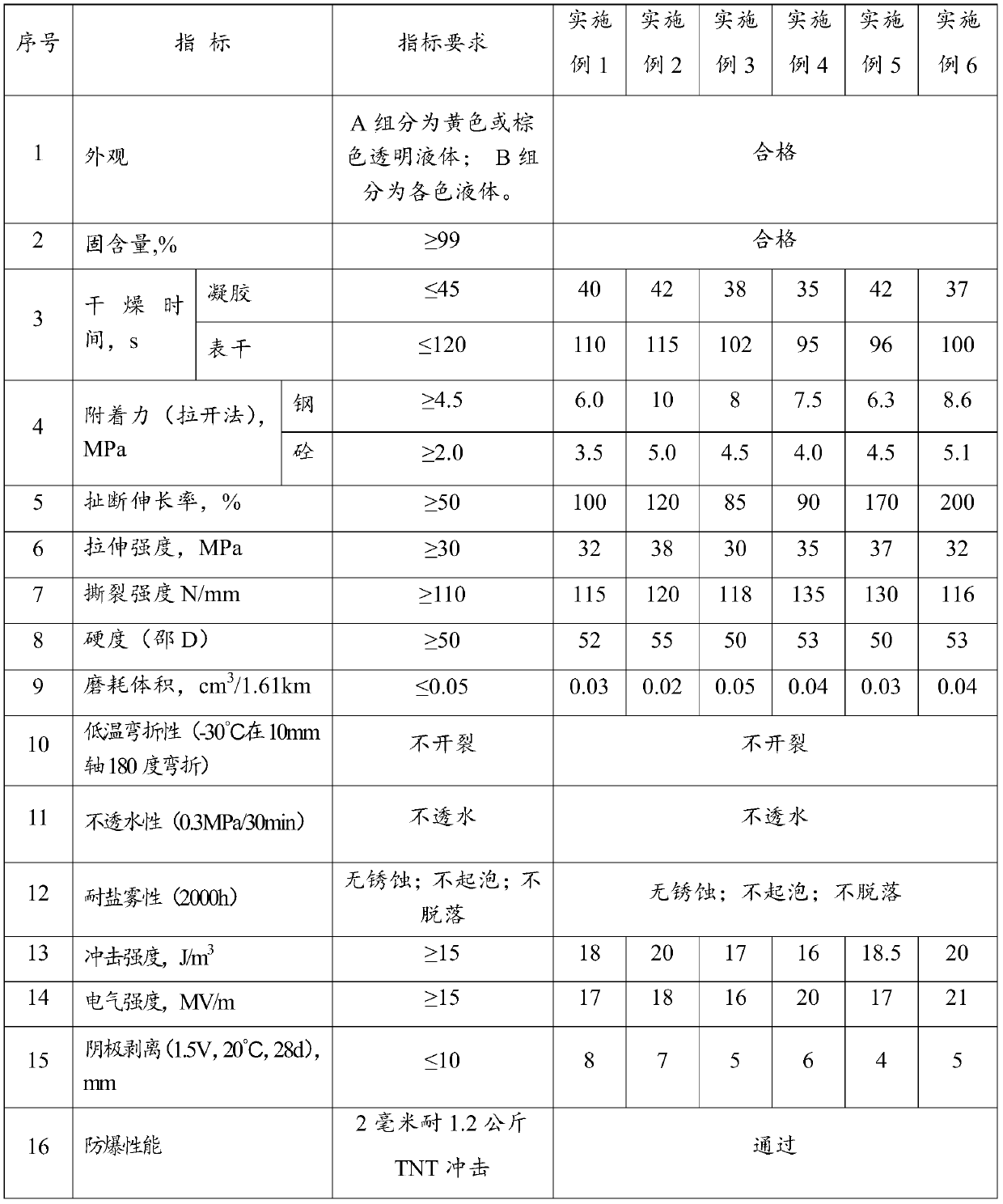

Embodiment 1

[0045] The preparation process of the slow-response high-performance explosion-proof polyurea material in this example is as follows:

[0046] (1) Preparation of component A prepolymer: Put 100 parts of PTMEG1000 into a reactor protected by nitrogen gas, heat to 95°C~100°C under stirring, dehydrate under vacuum -0.1MPa for 4h, release the vacuum, and lower the temperature Add 100 parts of IPDI to below 40°C, react at 80°C for 3 hours, after the reaction, cool down to below 60°C, add 10 parts of propylene carbonate, stir for 10 minutes, measure -NCO value, discharge, filter and pack to obtain -NCO content 14% isocyanate prepolymer.

[0047] (2) Preparation of component B: Weigh the components according to the order of the formula, 30 parts of amino-terminated polyether D2000, 20 parts of PTMEG1000, 10 parts of polyaspartic acid ester F420, 2 parts of light stabilizer 770, 35 parts The chain extender Clearlink1000, 0.1 parts of catalyst bismuth isooctanoate, 5 parts of 3A molec...

Embodiment 2

[0049] The preparation process of the slow-response high-performance explosion-proof polyurea material in this example is as follows:

[0050] (1) Preparation of A-component prepolymer: put 100 parts of Fomrez111-56 into a reactor protected by nitrogen gas, heat to 95°C~100°C under stirring, dehydrate under vacuum -0.1MPa for 6h, and release the vacuum , add 130 parts of HMDI after cooling down to below 40°C, and react at 80°C for 3 hours. After the reaction, cool down to below 60°C and add 20 parts of ethyl carbonate (EC), stir for 10 minutes to measure -NCO value, then discharge, filter and pack. An isocyanate prepolymer with an -NCO content of 13.3% was obtained.

[0051] (2) Preparation of component B: Weigh each component according to the order of the formula, mix 60 parts of amino-terminated polyether D2000, 20 parts of polyaspartate NH2850, 1 part of UV-1164, 20 parts of chain extender Unilink4200, Put 1 part of 4A molecular sieve and 5 parts of color paste into the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com