Automatic pruning machine for expressway halving belt anti-dazzle plants

A highway and automatic pruning technology, which is applied in the fields of plant waste crushing, hedge trimming equipment, botanical equipment and methods, etc., can solve the problem of high manual construction cost of anti-glare plant pruning, easy aging and short life of anti-glare panels, which cannot be realized. Standardized construction and other issues, to achieve the effect of good trimming effect, reliable performance and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

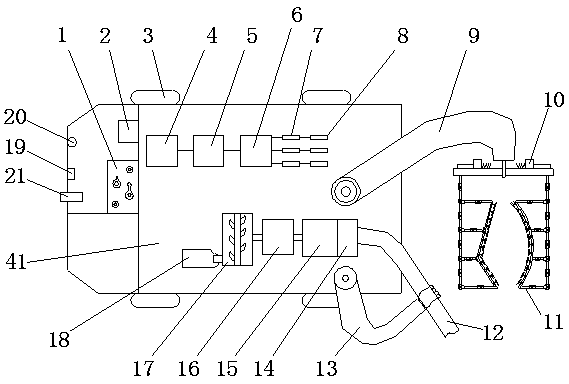

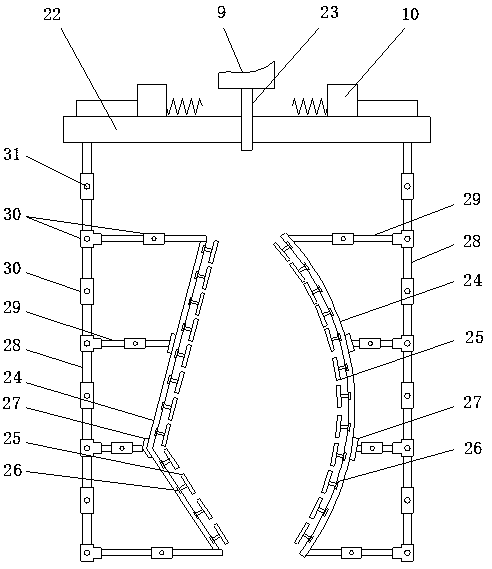

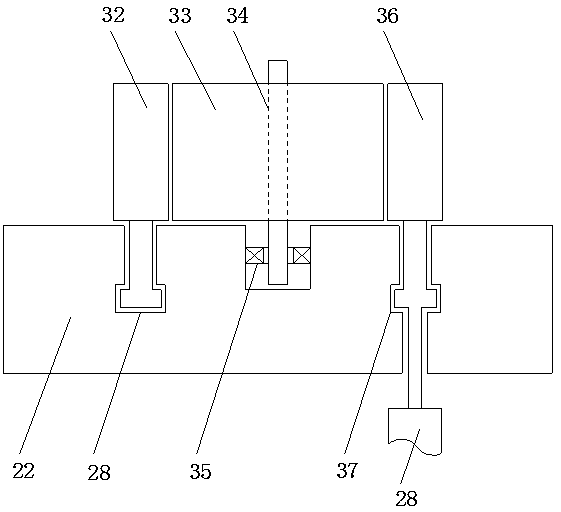

[0034] Such as Figure 1-4As shown, the automatic pruning machine with anti-glare plants in the middle of the highway includes a power system, a walking system, a pruning system, a branch and leaf collection system, a branch and leaf processing system, an intelligent system and a control system. The power system consists of an engine, a gearbox, a transfer Box, hydraulic motor, hydraulic pump, the engine power enters the transfer case through the gearbox, the walking system is composed of the engine, gearbox, transfer case, differential, drive axle, tires, the power system and the walking system are set in In the frame, the blades are installed on the knife holder when in use. A knife holder is evenly distributed with 3 blades on the circumference of the garden. The diameter of the blade is 5cm. The number of blade holders is determined according to the length of the high-strength elastic tube. 11cm, the number of adjustment rods is determined according to the length of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com