Microwave treatment method and system for continuously increasing digestion resistance of potato starch

A potato starch and microwave treatment technology, which is applied in the field of food processing, can solve the problems of device and material development lag, and hinder the application of microwave in resistant starch, so as to improve the digestion resistance and increase the formation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

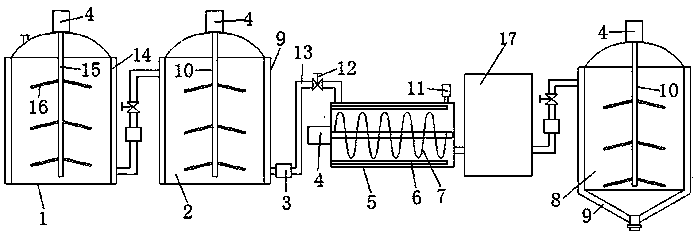

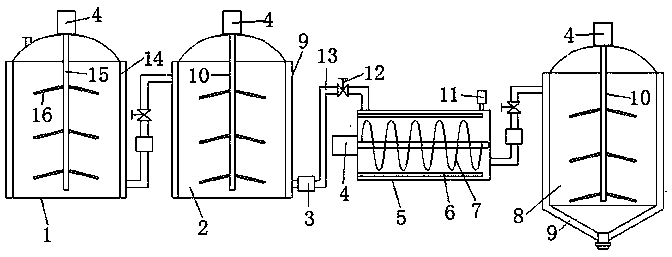

[0059] A microwave treatment system that can continuously improve the digestion resistance of starch, such as figure 1 As shown, it comprises a mixing heating tank 1, a mixing cooling tank 2, a reaction tank 5, an ultra-high pressure vessel 17 and a cooling tank 8, and a mixing heating tank 1, a mixing cooling tank 2, a reaction tank 5 and a cooling tank 8 pass through the The feeding pipe 13 of the pump 3 and the check valve 12 is connected in sequence, and the feeding pump 3 and the check valve 12 are sequentially arranged on the feeding pipe 13 along the conveying direction of the material, and the starch in the previous process can be pumped through the feeding pump 3 To the next process, and the check valve 12 can ensure that the material will not flow back during the conveying process.

[0060] The outside of the mixing heating tank 1 is covered with a heating jacket 14, and the heating jacket 14 is provided with a medium inlet and a medium outlet. The heating medium in ...

Embodiment 1B

[0068] The difference with the structure of Example 1A is that a microwave treatment system that can continuously improve the digestion resistance of starch, such as figure 1 As shown, it includes a mixing heating tank 1, a mixing cooling tank 2, a reaction tank 5 and a cooling tank 8, and the mixing heating tank 1, the mixing cooling tank 2, the reaction tank 5 and the cooling tank 8 respectively pass through with a feeding pump 3 and a backstop The feeding pipe 13 of the valve 12 is connected in sequence, and the feeding pump 3 and the check valve 12 are sequentially arranged along the conveying direction of the material on the feeding pipe 13, and the starch in the previous process can be pumped to the next process through the feeding pump 3, And the check valve 12 can ensure that the material will not flow back during the conveying process. The reaction tank 5 is a tank body that can be pressurized, and its pressure can reach about 150MPa. Simultaneously with microwave tr...

Embodiment 2

[0070] The method for continuously improving the microwave treatment of potato starch digestion resistance comprises the following steps:

[0071] In (1), weigh the potato tubers, wash off the surface sediment, cut into cubes, add water, the ratio of material to liquid is 1:2, beat, stand for 3 hours, filter, wash the filter residue with water, stand still, and then pour off the upper layer liquid, to obtain a starch emulsion;

[0072] (2) Heat the potato starch emulsion in (1) to 55°C in a mixing heating tank, then transport it to a mixing cooling tank to cool to 32°C after cooling, then transport it to a microwave generator, and transport it to an ultra-high pressure container after microwave treatment. Ultra-high pressure treatment, and then enter the cooling tank for cooling; the power of microwave treatment is 300W, and the treatment is 100s; the pressure of ultra-high pressure treatment is 580MPa;

[0073](3) Leave the cooled starch milk in (2) for 5 hours, filter, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com