Lignin micro/nano balls, reinforced polylactic acid 3D printing material and preparation method thereof

A technology of 3D printing and polylactic acid, which is applied in the field of lignin micro/nanospheres, reinforced polylactic acid 3D printing materials and its preparation, can solve problems such as shear thinning, achieve tensile strength and bending strength improvement, and high gloss degree, increase the effect of 3D printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

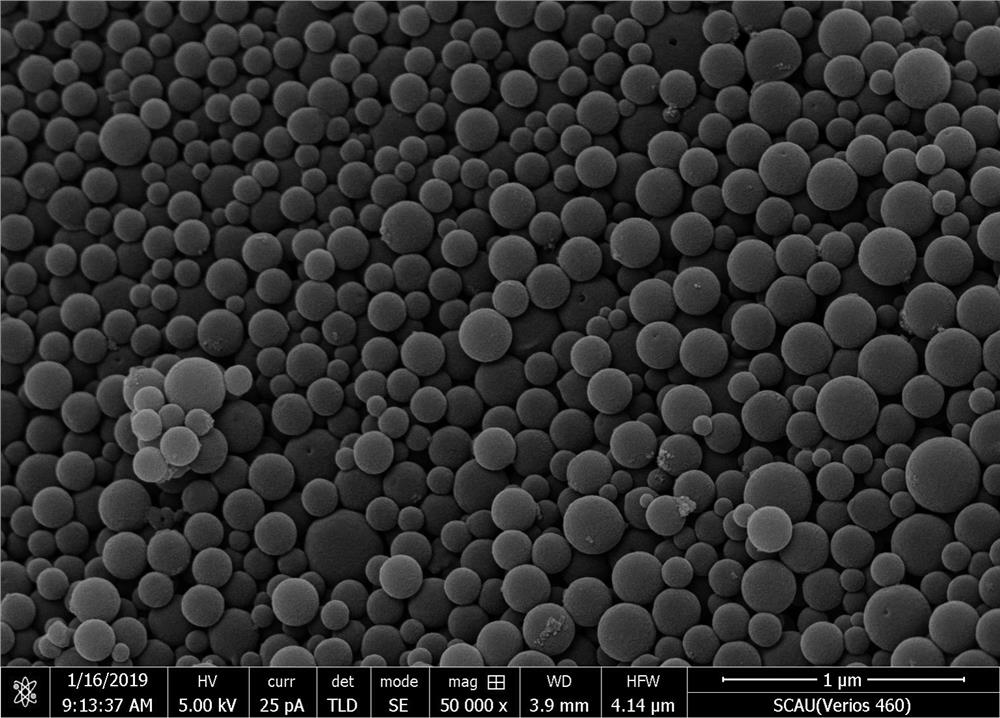

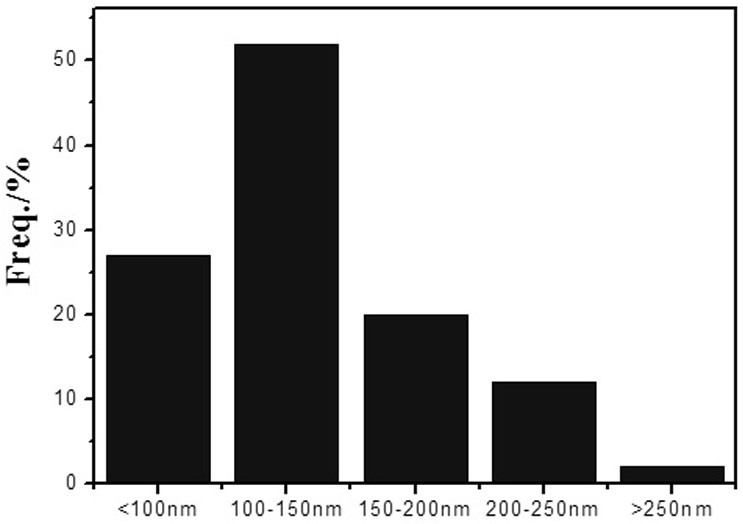

Image

Examples

Embodiment 1

[0033] (1) Weigh 1 g of polyvinyl alcohol with a molecular weight of 1500 into a beaker filled with 0.5 L of water, and heat it at 80°C until the polyvinyl alcohol is completely dissolved to form a 2 g / L polyvinyl alcohol aqueous solution.

[0034] (2) Take 0.25 g of organic solvent lignin in a 500 mL beaker, add 100 mL of tetrahydrofuran, and emulsify at a high speed of 10000 r / min for 30 s to form a suspension of lignin and organic solvent with a concentration of 2.5 g / L. Add 200 mL of the polyvinyl alcohol aqueous solution prepared in step (1) to the above suspension, and stir for 4 h at a water bath temperature of 30 °C to form an emulsion with a volume ratio of water to organic solvent of 2.

[0035] (3) Take out the emulsion obtained in step (2) in batches, put it into a centrifuge test tube, and perform centrifugation at a speed of 9000 r / min and a centrifugation time of 10 min, remove the filtrate, and then wash with deionized water until the filtrate It is neutral and...

Embodiment 2

[0043] (1) Weigh 2 g of polyvinyl alcohol with a molecular weight of 2000 into a beaker filled with 0.5 L of water, and heat it at 80°C until the polyvinyl alcohol is completely dissolved to form a 4 g / L polyvinyl alcohol aqueous solution.

[0044] (2) Take 0.5 g of cellulase lignin in a 500 mL beaker, add 100 mL of N,N-dimethylformamide, emulsify at a speed of 12000 r / min for 30 s, and form a concentration of 5 g / L lignin and organic solvent suspension. Add 300 mL of the polyvinyl alcohol aqueous solution prepared in step (1) to the above suspension, and stir for 4 h at a water bath temperature of 40 °C to form an emulsion with a volume ratio of water to organic solvent of 3.

[0045] (3) Take out the emulsion obtained in step (2) in batches, put it into a centrifuge test tube, and carry out centrifugation at a speed of 6000 r / min and a centrifugation time of 10 min, remove the filtrate, and then wash with deionized water until the filtrate It is neutral and colorless, and l...

Embodiment 3

[0050] (1) Weigh 3 g of polyvinyl alcohol with a molecular weight of 3000 into a beaker filled with 0.5 L of water, and heat it at 80°C until the polyvinyl alcohol is completely dissolved to form a 6 g / L polyvinyl alcohol aqueous solution.

[0051] (2) Take 0.25 g of sulfuric acid lignin in a 500 mL beaker, add 100 mL of dichloromethane, and emulsify at a high speed of 14000 r / min for 30 s to form a suspension of lignin and organic solvent with a concentration of 2.5 g / L liquid. Add 300 mL of the polyvinyl alcohol aqueous solution prepared in step (1) to the above suspension, and stir for 4 h at a water bath temperature of 50 °C to form an emulsion with a volume ratio of water to organic solvent of 3.

[0052] (3) Take out the emulsion obtained in step (2) in batches, put it into a centrifuge tube, and carry out centrifugation at a speed of 8000 r / min and a centrifugation time of 10 min, remove the filtrate, and then wash with deionized water until the filtrate It is neutral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com