Pre-paved flexible steel concrete type polymer rock waterproof coiled material and structural waterproof material

A waterproof membrane and polymer technology, which is applied to roofs, building components, and layered products using flexible materials, can solve the problems of reduced waterproof performance, poor impermeability, and difficult construction, and achieves protection of waterproof membranes, Improved firmness and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

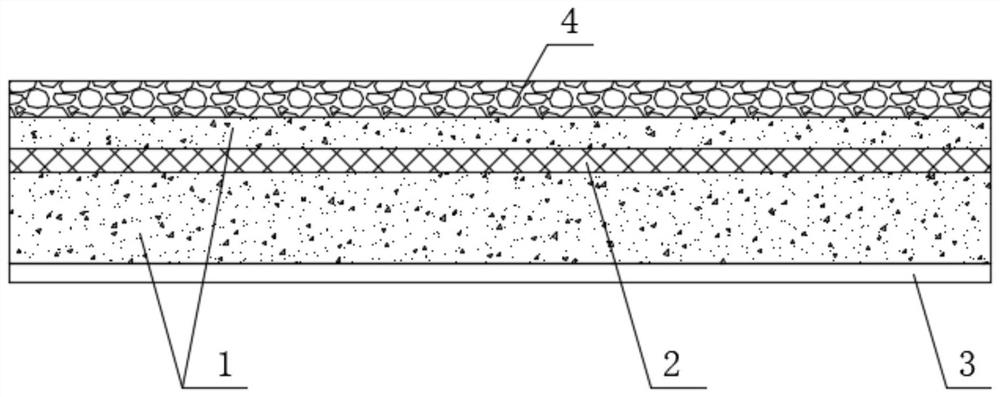

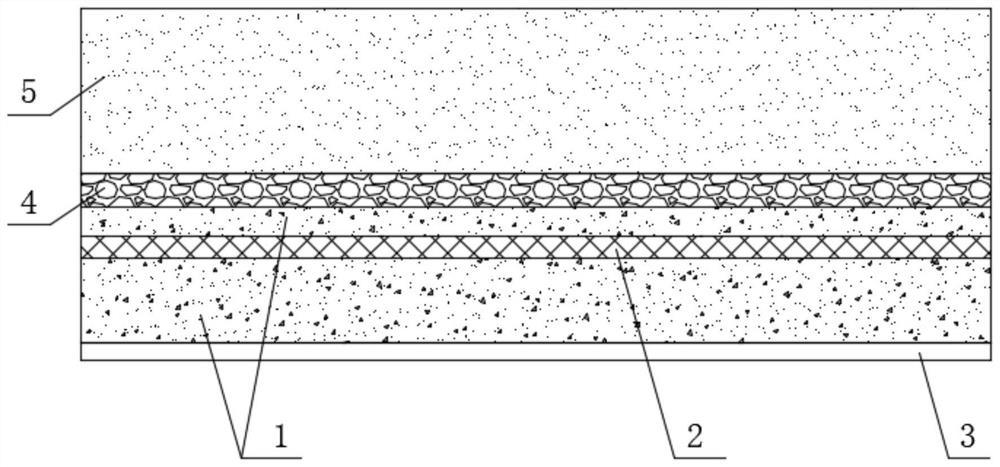

[0031] Please refer to figure 1 The illustrated embodiment, a kind of pre-paved flexible steel concrete polymer rock waterproofing membrane, comprises polyester non-woven fabric 2, and preferred polyester non-woven fabric 2 is encrypted super-stretch polyester non-woven fabric, because The waterproof membrane adopts encrypted super-strength polyester non-woven fabric, so the waterproof membrane has a high tensile force, which overcomes the traditional asphalt waterproof membrane with low tensile force. During construction, the inner and outer corners are firstly made with additional layers. The problem is that the polyester non-woven fabric 2 is equipped with a high-molecular asphalt mixed layer 1. The high-molecular asphalt mixed layer 1 is mainly composed of high-temperature resistant heavy rubber asphalt, rubber powder and thermoplastic polyolefin. Polymerization modification of heavy rubber asphalt can improve the impermeability and aging resistance of the original asphalt...

Embodiment 2

[0042] Please refer to figure 1 The illustrated embodiment, a kind of pre-paved flexible steel concrete polymer rock waterproofing membrane, comprises polyester non-woven fabric 2, and preferred polyester non-woven fabric 2 is encrypted super-stretch polyester non-woven fabric, because The waterproof membrane adopts encrypted super-strength polyester non-woven fabric, so the waterproof membrane has a high tensile force, which overcomes the traditional asphalt waterproof membrane with low tensile force. During construction, the inner and outer corners are firstly made with additional layers. The problem is that the polyester non-woven fabric 2 is equipped with a high-molecular asphalt mixed layer 1. The high-molecular asphalt mixed layer 1 is mainly composed of high-temperature resistant heavy rubber asphalt, rubber powder and thermoplastic polyolefin. Polymerization modification of heavy rubber asphalt can improve the impermeability and aging resistance of the original asphalt...

Embodiment 3

[0053] Please refer to figure 1 The illustrated embodiment, a kind of pre-paved flexible steel concrete polymer rock waterproofing membrane, comprises polyester non-woven fabric 2, and preferred polyester non-woven fabric 2 is encrypted super-stretch polyester non-woven fabric, because The waterproof membrane adopts encrypted super-strength polyester non-woven fabric, so the waterproof membrane has a high tensile force, which overcomes the traditional asphalt waterproof membrane with low tensile force. During construction, the inner and outer corners are firstly made with additional layers. The problem is that the polyester non-woven fabric 2 is equipped with a high-molecular asphalt mixed layer 1. The high-molecular asphalt mixed layer 1 is mainly composed of high-temperature resistant heavy rubber asphalt, rubber powder and thermoplastic polyolefin. Polymerization modification of heavy rubber asphalt can improve the impermeability and aging resistance of the original asphalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com