Preparation method and application of visible-light response iron oxide doped nitrogen-deficient carbon nitride composite material

A composite material and visible light technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and water treatment of special compounds, can solve the problems of easy recombination of photogenerated carriers, reduced photocatalytic activity, and low photocatalytic efficiency. The raw materials are cheap and easy to obtain, convenient for mass production, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

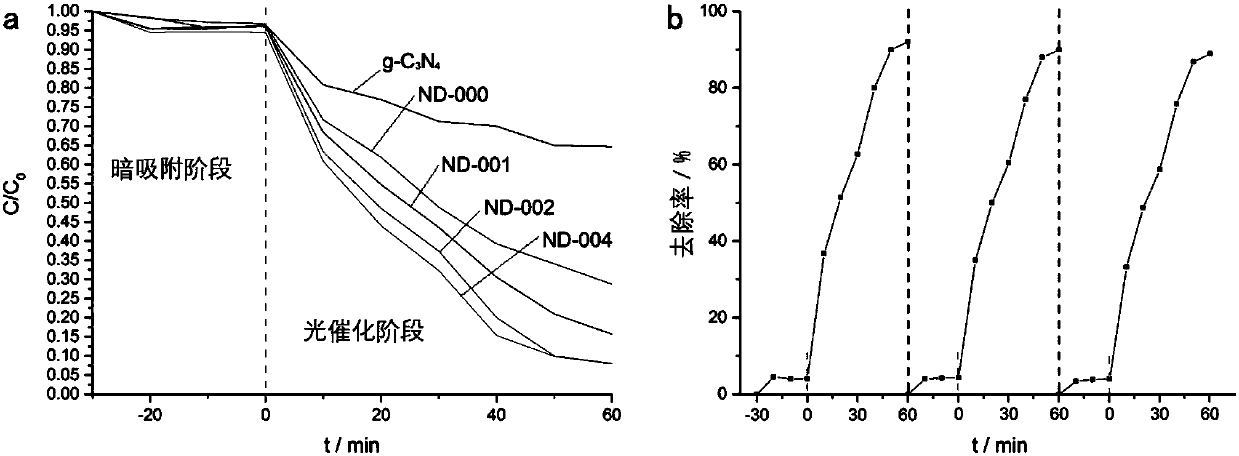

Examples

preparation example Construction

[0027] A visible light-responsive Fe 2 o 3 / nd-g-C 3 N 4 The preparation method of composite material, comprises the following steps:

[0028] Step 1) dicyandiamide is placed in the baking oven and dried, and after grinding, it is mixed with ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) mix and put into an alumina crucible, heat up and calcinate after being covered and semi-closed. After the calcination, it was naturally placed and cooled to room temperature to obtain Fe 2 o 3 / nd-g-C 3 N 4 crude product;

[0029] Step 2) with the Fe that step 1 obtains 2 o 3 / nd-g-C 3 N 4 The crude product was added to distilled water: ethanol 1:1 solution, ultrasonically oscillated, and after centrifugation, the precipitate was taken and washed with distilled water to obtain Fe 2 o 3 / nd-g-C 3 N 4 product;

[0030] Step 3) with the Fe that step 2 obtains 2 o 3 / nd-g-C 3 N 4 The product is dried to obtain Fe 2 o 3 / nd-g-C 3 N 4 composite material.

[0031] In step 1...

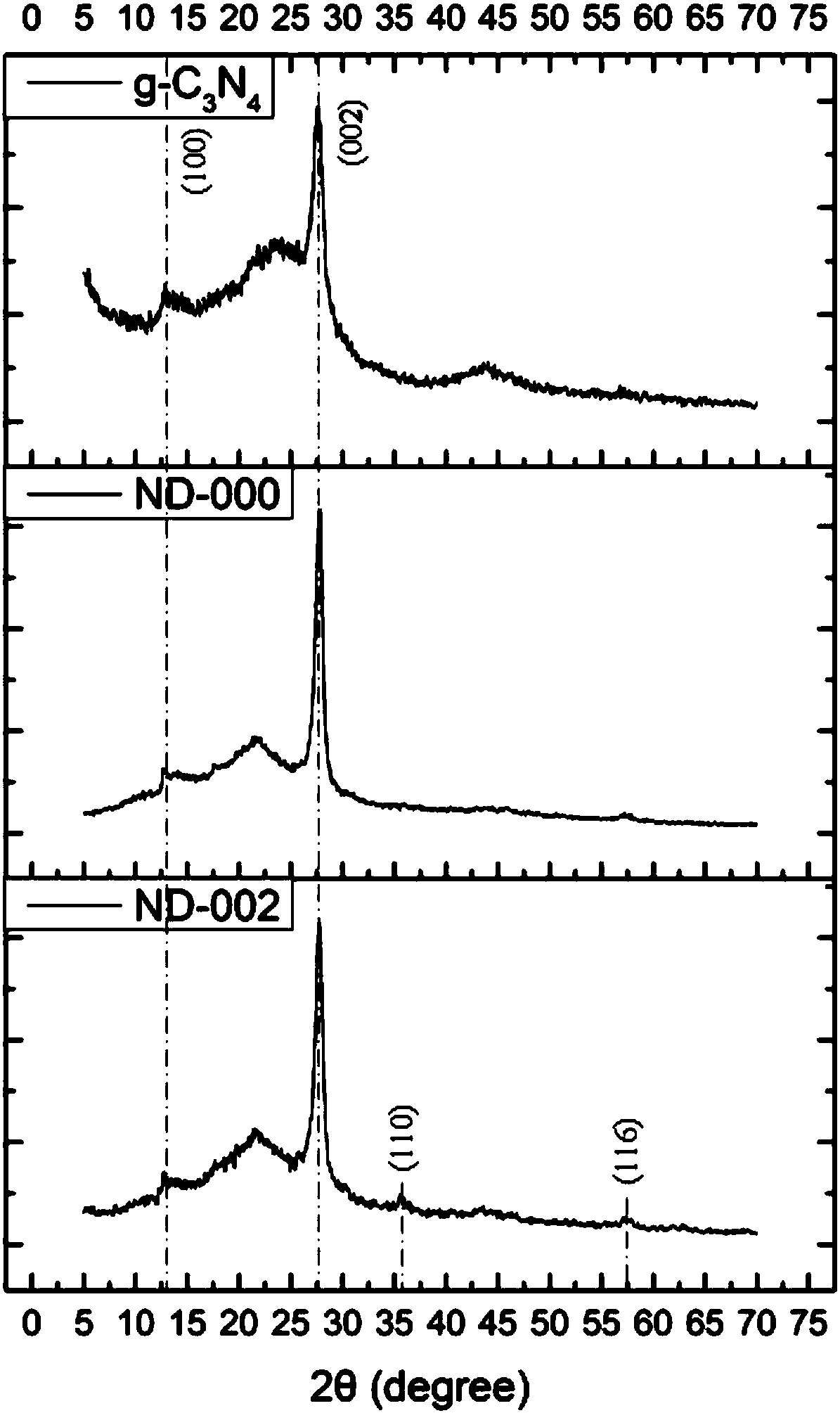

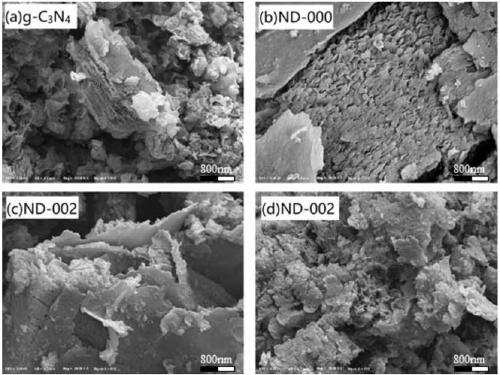

Embodiment 1

[0035] Step 1: Put 5g of dicyandiamide in an oven at 60°C for 12h, grind it with 0.1653g of FeSO 4 ·7H 2 O mixed evenly, put into an alumina crucible, and calcined at 600°C for 4h with a heating rate of 2.3°C / min. After calcination, let it cool down to room temperature naturally, and get powdered Fe after grinding. 2 o 3 / nd-g-C 3 N 4 crude product;

[0036] Step 2: the Fe obtained in step 1 2 o 3 / nd-g-C 3 N 4 The crude product was added to 200mL distilled water: ethanol 1:1 solution, ultrasonically oscillated at 100W for 6h, and then centrifuged at 10,000 rpm for 10min, the precipitate was taken and washed with distilled water to obtain Fe 2 o 3 / nd-g-C 3 N 4 product;

[0037] Step 3: the Fe obtained in step 2 2 o 3 / nd-g-C 3 N 4 The product was dried at 60°C for 12 hours to obtain Fe 2 o 3 / nd-g-C 3 N 4 Composite material, denoted as ND-001, its C 3 N 4 The molar ratio with Fe element is 1:0.01.

Embodiment 2

[0039] Step 1: Put 5g of dicyandiamide in an oven at 60°C for 12 hours, grind it with 0.3307g of FeSO 4 ·7H 2 O mixed evenly, put into an alumina crucible, and calcined at 600°C for 4h with a heating rate of 2.3°C / min. After calcination, let it cool down to room temperature naturally, and get powdered Fe after grinding. 2 o 3 / nd-g-C 3 N 4 crude product;

[0040] Step 2: the Fe obtained in step 1 2 o 3 / nd-g-C 3 N 4 The crude product was added to 200mL distilled water: ethanol 1:1 solution, ultrasonically oscillated at 100W for 6h, and then centrifuged at 10,000 rpm for 10min, the precipitate was taken and washed with distilled water to obtain Fe 2 o 3 / nd-g-C 3 N 4 product;

[0041] Step 3: the Fe obtained in step 2 2 o 3 / nd-g-C 3 N 4 The product was dried at 60°C for 12 hours to obtain Fe 2 o 3 / nd-g-C 3 N 4 Composite material, denoted as ND-002, its C 3 N 4 The molar ratio with Fe element is 1:0.02;

[0042] As a comparison, in step 1, the dried dic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com