A kind of loaded ultra-small Prussian blue analogue and its preparation method and application

A technology of Prussian blue and analogs, applied in the field of supported ultra-small Prussian blue analogs and their preparation, can solve problems such as unseen Prussian blue structures, and achieve the effects of high catalytic activity, mild reaction conditions, and improved electrical capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

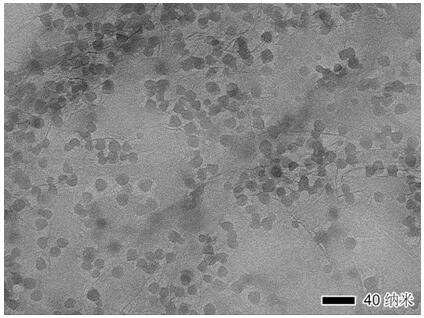

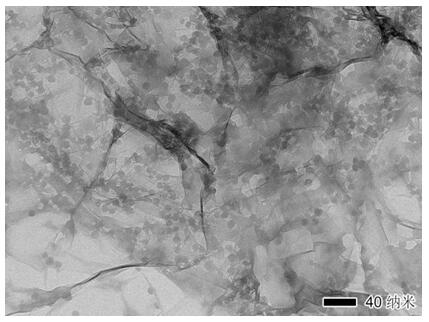

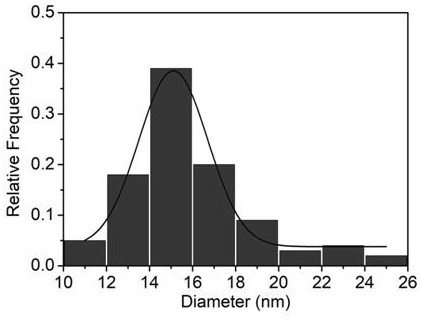

[0037] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0038] a) The trivalent metal compound, the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound, the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 5:5:4000:10:1; the reaction conditions are: reaction temperature 100°C, reaction time 2 days;

[0039] b) Disperse the graphene-loaded ultra-small Prussian blue analogue in the first solvent, and add a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analogue after graphene reduction; graphene-loaded The weight ratio of the ultra-small Prussian blue analogue, the first solvent, the reducing agent, and the basic drug is 4000:50000:150:1; the reaction con...

Embodiment 2

[0043] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0044] a) The trivalent metal compound, the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound and the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 1:5:1000:10:1; the reaction conditions are: reaction temperature 10°C, reaction time 7 days;

[0045] b) Disperse the graphene-loaded ultra-small Prussian blue analogue in the first solvent, and add a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analogue after graphene reduction; graphene-loaded The weight ratio of the ultra-small Prussian blue analogue, the first solvent, the reducing agent, and the basic drug is 5000:50000:200:1; the reaction c...

Embodiment 3

[0049] A preparation method of graphene-loaded ultra-small Prussian blue analogues specifically comprises the following steps:

[0050] a) The trivalent metal compound and the divalent metal compound, the first solvent, the ligand and graphene are mixed and reacted and washed to prepare the graphene-loaded ultra-small Prussian blue analogue; the trivalent metal compound and the divalent metal source compound, The weight ratio of the first solvent, ligand and graphene is 10:9:5000:10:1; the reaction conditions are: reaction temperature 180°C, reaction time 1 day;

[0051] b) Dispersing the graphene-loaded ultra-small Prussian blue analog in the first solvent, adding a reducing agent and an alkaline solution to mix and react to prepare the graphene-loaded ultra-small Prussian blue analog after graphene reduction. The weight ratio of the ultra-small Prussian blue analogue loaded on graphene, the first solvent, the reducing agent, and the basic drug is 10000:50000:150:1; the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com