Hybrid power drive system

A transmission system and hybrid technology, applied in the field of machinery, can solve the problems of difficult to maintain accurate axis position, difficult to control NVH performance, low transmission accuracy, etc., to simplify the structure, improve NVH performance, and improve the effect of transmission accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

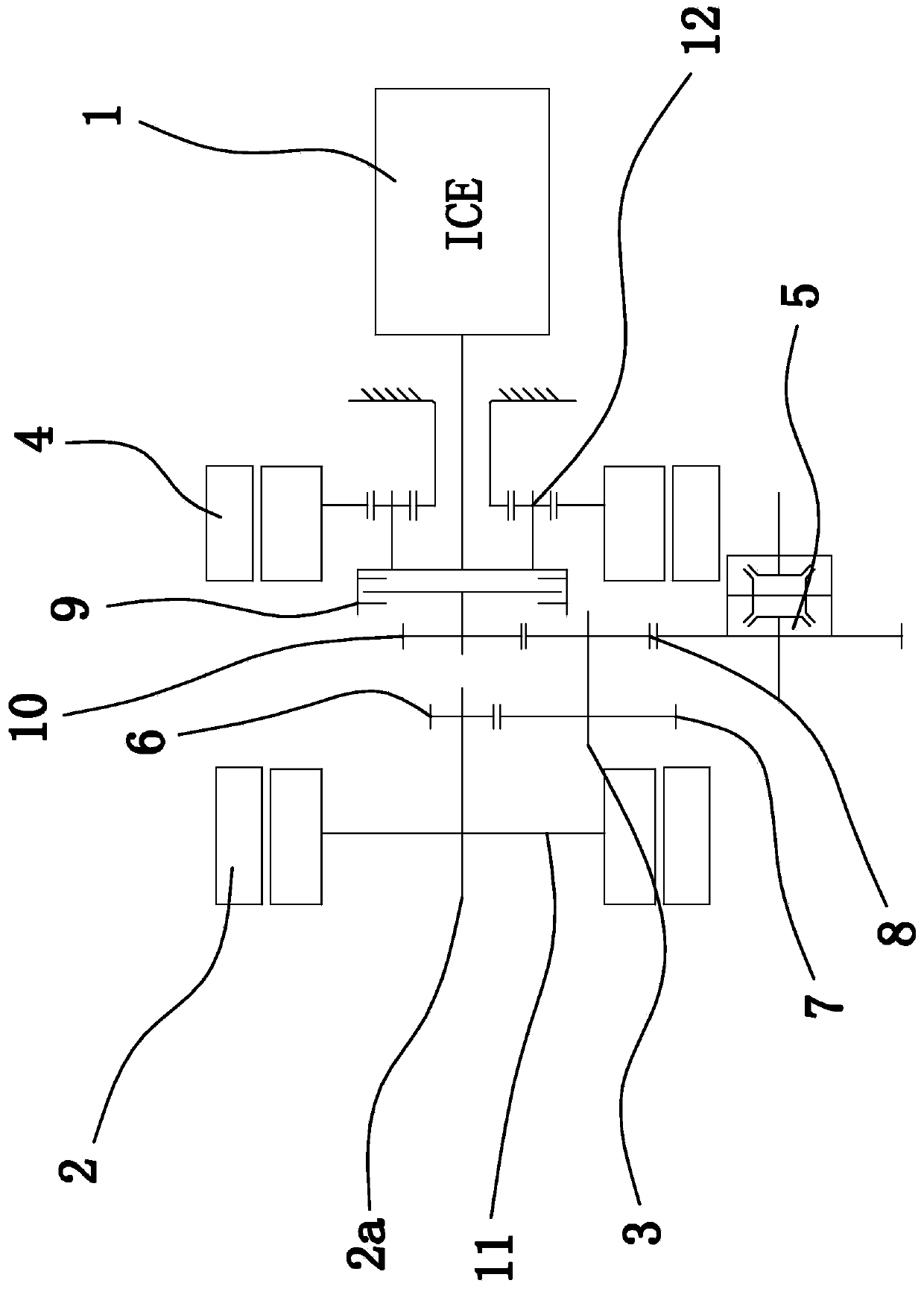

[0023] Such as figure 1 As shown, the hybrid power transmission system includes an engine 1 , a drive motor 2 , an output shaft 3 , a generator 4 capable of delivering electric energy to the drive motor 2 , and a differential 5 connected to wheels. The driving motor 2 is powered by a power battery, and the generator 4 is electrically connected to the power battery and can deliver electric energy for charging the power battery.

[0024] The input shaft 2a of drive motor 2 is provided with driving gear one 6, and the two ends of output shaft 3 are respectively provided with intermediate gear one 7 and intermediate gear two 8, and the diameter of intermediate gear one 7 is greater than the diameter of intermediate gear two 8, and driving gear The diameter of one 6 is less than the diameter of intermediate gear one 7, driving gear one 6 is meshed with intermediate gear one 7, intermediate gear two 8 is meshed with the gears on the differential 5 and connected. The rotating shaft ...

Embodiment 2

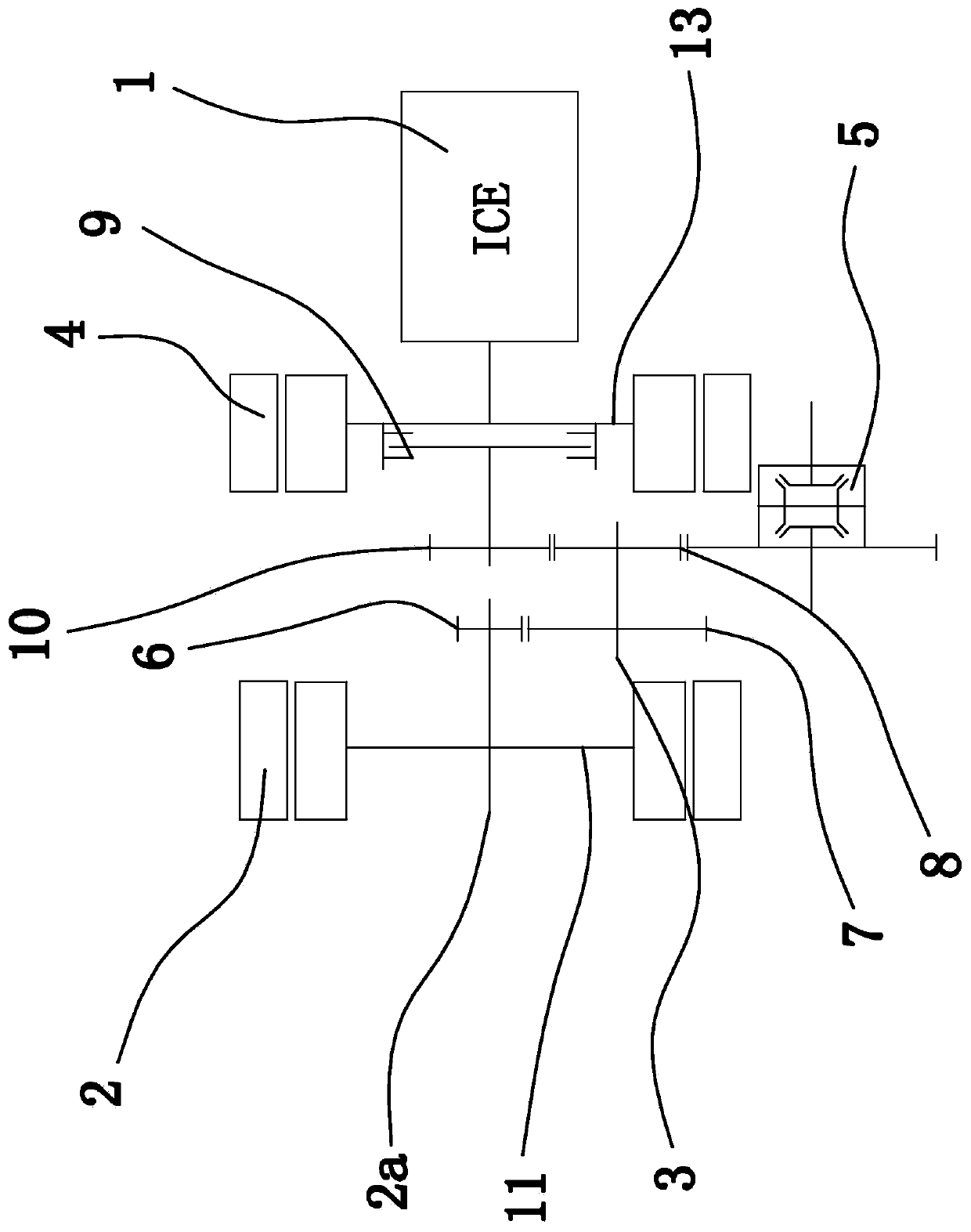

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference being that:

[0035] Such as figure 2 As shown, if the economic speed of the generator 4 is matched with the economic speed of the engine 1, that is, the high-efficiency areas of the engine 1 and the generator 4 have a large overlap, and the rotating shaft of the engine 1 and the inner ring of the rotor of the generator 4 Connected by connecting piece 13. In this embodiment, the connecting member 13 is a spline or the connecting plate 11 or is directly connected by a key, thereby further reducing the axial and radial dimensions and reducing the cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com