Method used for synthesis of 3D skeleton@MOFs water processor taking 3D skeleton as metal source

A water treatment and skeleton technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as complicated operation and heavy metal pollution, and achieve the effect of solving pollution problems and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

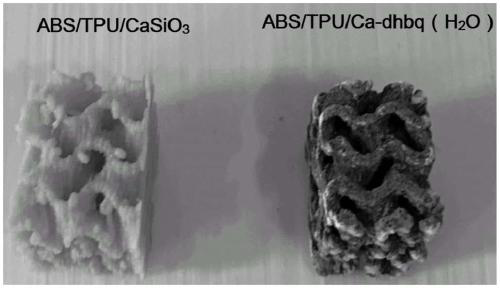

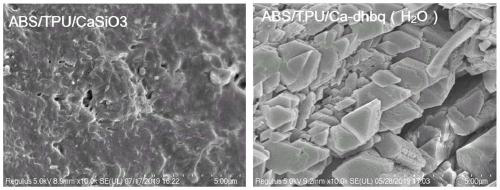

[0031] (1) According to 7kgABS, 3kgTPU, 2kgCaSiO 3 After mixing, it is granulated by screw melt extrusion and melt blending. The parameters of the twin-screw extruder are: 130°C in zone 1, 145°C in zone 2, 160°C in zone 3, 185°C in zone 4, 200°C in zone 5, and 200°C in zone 6. 210°C, 205°C in the seventh zone, 205°C in the eighth zone, 200°C in the ninth zone, 190°C at the die head, 200 rpm, extruded and granulated to obtain wire masterbatch; add 10.0 kg of wire masterbatch to single-screw extrusion Processing in the machine, the parameters of the single-screw extruder are: zone 1 200°C, zone 2 210°C, zone 3 205°C, zone 4 200°C, the speed is 50 rpm, the extruded silk is cooled by water, pulled and controlled by a tractor The wire diameter of the wire is obtained to obtain the 3D printing wire, and the specific 3D printing device is made (see figure 1 ABS / TPU / CaSiO on the left 3 Sample picture, electron microscope picture see figure 2 ABS / TPU / CaSiO on the left 3 electron m...

Embodiment 2

[0038] (1) According to 7kgABS, 3kgTPU, 2kgCaCO 3After mixing, it is granulated by screw melt extrusion and melt blending. The parameters of the twin-screw extruder are: 130°C in zone 1, 145°C in zone 2, 160°C in zone 3, 185°C in zone 4, 200°C in zone 5, and 200°C in zone 6. 210°C, 205°C in the seventh zone, 205°C in the eighth zone, 200°C in the ninth zone, 190°C die head, 200 rpm, extruded and granulated to obtain wire masterbatch; add 10.0kg wire masterbatch to single-screw extrusion Processing in the machine, the parameters of the single-screw extruder are: zone 1 200°C, zone 2 210°C, zone 3 205°C, zone 4 200°C, the speed is 50 rpm, the extruded silk is cooled by water, pulled and controlled by a tractor The wire diameter of the wire is obtained to obtain a 3D printing wire and make a specific 3D printing device;

[0039] (2) Place the 3D printed device in acetone and etch for 5 minutes;

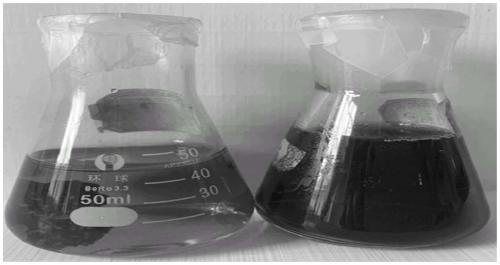

[0040] (3) Dissolve 0.75g of 2,5-dihydroxy-1,4-benzoquinone in 50mL of water and s...

Embodiment 3

[0044] (1) According to 7kgABS, 3kgTPU, 2kgCaSiO 3 After mixing, it is granulated by screw melt extrusion and melt blending. The parameters of the twin-screw extruder are: 130°C in zone 1, 145°C in zone 2, 160°C in zone 3, 185°C in zone 4, 200°C in zone 5, and 200°C in zone 6. 210°C, 205°C in the seventh zone, 205°C in the eighth zone, 200°C in the ninth zone, 190°C at the die head, 200 rpm, extruded and granulated to obtain wire masterbatch; add 10.0 kg of wire masterbatch to single-screw extrusion Processing in the machine, the parameters of the single-screw extruder are: zone 1 200°C, zone 2 210°C, zone 3 205°C, zone 4 200°C, the speed is 50 rpm, the extruded silk is cooled by water, pulled and controlled by a tractor The wire diameter of the wire is obtained to obtain a 3D printing wire and make a specific 3D printing device;

[0045] (2) Place the 3D printed device in acetone and etch for 5 minutes;

[0046] (3) Immerse the etched 3D printed device in distilled water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com