Environment-friendly inorganic thermal insulation material and preparation method thereof

An inorganic thermal insulation material, an environmentally friendly technology, applied in the field of thermal insulation materials, can solve the problems of poor compression resistance, insufficient bonding strength, poor heat insulation performance, etc., to achieve enhanced anti-corrosion performance and compression performance, excellent fire and anti-corrosion performance, Excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

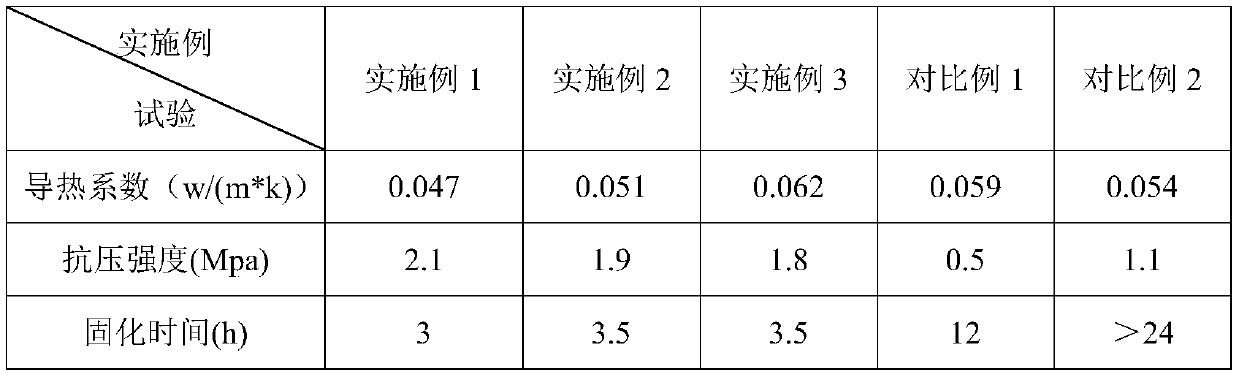

Embodiment 1

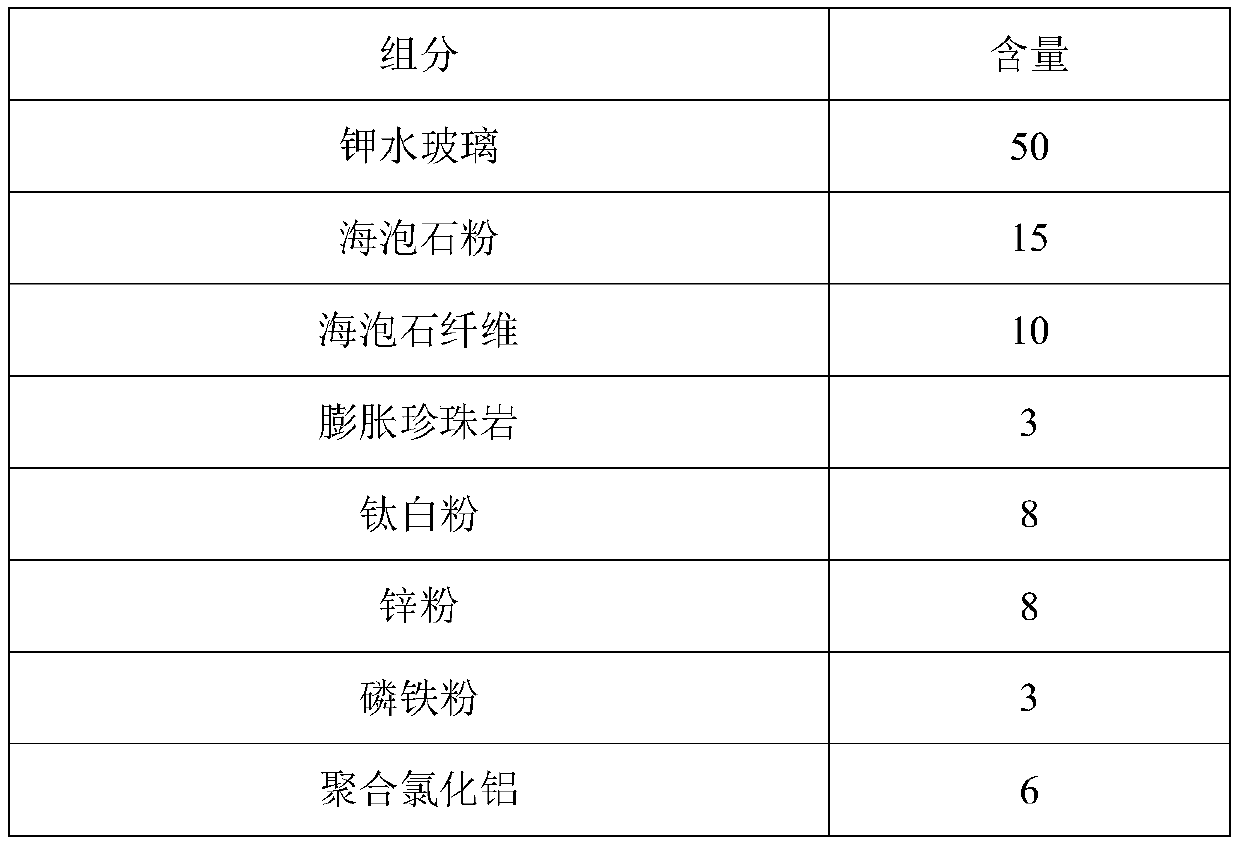

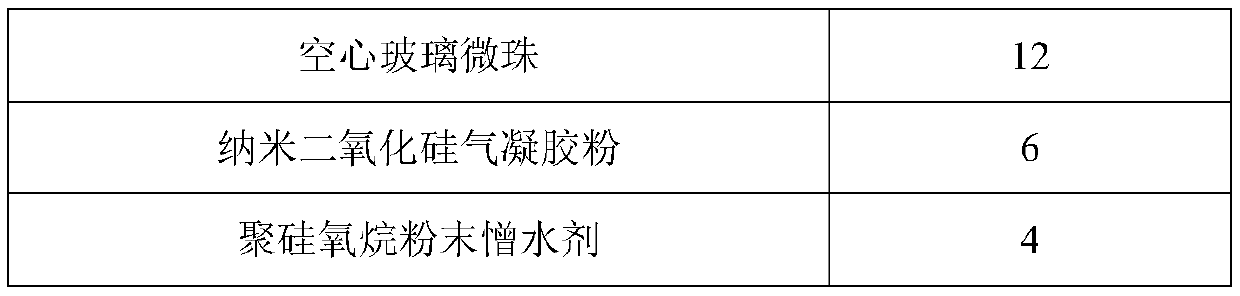

[0017] The components and contents of the raw materials of the environment-friendly inorganic thermal insulation material are shown in Table 1 below.

[0018] The insulation material component and content of table 1 embodiment 1

[0019]

[0020]

[0021] The preparation method of the insulation material comprises the following steps:

[0022] (1) Add titanium dioxide and sepiolite powder into potassium silicate and stir and disperse for 20 minutes according to parts by weight, add expanded perlite and sepiolite fiber and stir at a high speed of 1500 r / min for 30 minutes to prepare mixture A;

[0023] (2) Zinc powder, ferrophosphorus powder, polyaluminum chloride, hollow glass microspheres, nano-silica airgel powder and polysiloxane powder water-repellent are mixed in parts by weight to prepare compound B;

[0024] (3) Mix the mixture A and the mixture B and stir them evenly to prepare the insulation material.

Embodiment 2

[0026] The components and contents of the raw materials of the environment-friendly inorganic thermal insulation material are shown in Table 2 below.

[0027] The insulation material component and content of table 2 embodiment 2

[0028] components content Potassium silicate 45 meerschaum powder 10 Sepiolite fiber 8 expanded perlite 3 Titanium dioxide 5 Zinc powder 8 Ferrophosphorus powder 5 PAC 5 hollow glass microspheres 10 Nano silica airgel powder 5 Polysiloxane Powder Hydrophobic Agent 3

[0029] The preparation method of the insulation material comprises the following steps:

[0030] (1) Add titanium dioxide and sepiolite powder into potassium silicate and stir and disperse for 20 minutes according to parts by weight, add expanded perlite and sepiolite fiber and stir at a high speed of 1500 r / min for 30 minutes to prepare mixture A;

[0031] (2) Zinc powder, ferrophosphorus powder, polyalum...

Embodiment 3

[0034] The components and contents of the raw materials of the environment-friendly inorganic thermal insulation material are shown in Table 3 below.

[0035] The insulation material component and content of table 3 embodiment 3

[0036] components content Potassium silicate 40 meerschaum powder 6 Sepiolite fiber 6 expanded perlite 1 Titanium dioxide 6 Zinc powder 5 Ferrophosphorus powder 5 PAC 4 hollow glass microspheres 8 Nano silica airgel powder 4 Polysiloxane Powder Hydrophobic Agent 2

[0037] The preparation method of the insulation material comprises the following steps:

[0038] (1) Add titanium dioxide and sepiolite powder into potassium silicate and stir and disperse for 20 minutes according to parts by weight, add expanded perlite and sepiolite fiber and stir at a high speed of 1500 r / min for 30 minutes to prepare mixture A;

[0039] (2) Zinc powder, ferrophosphorus powder, polyalumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com