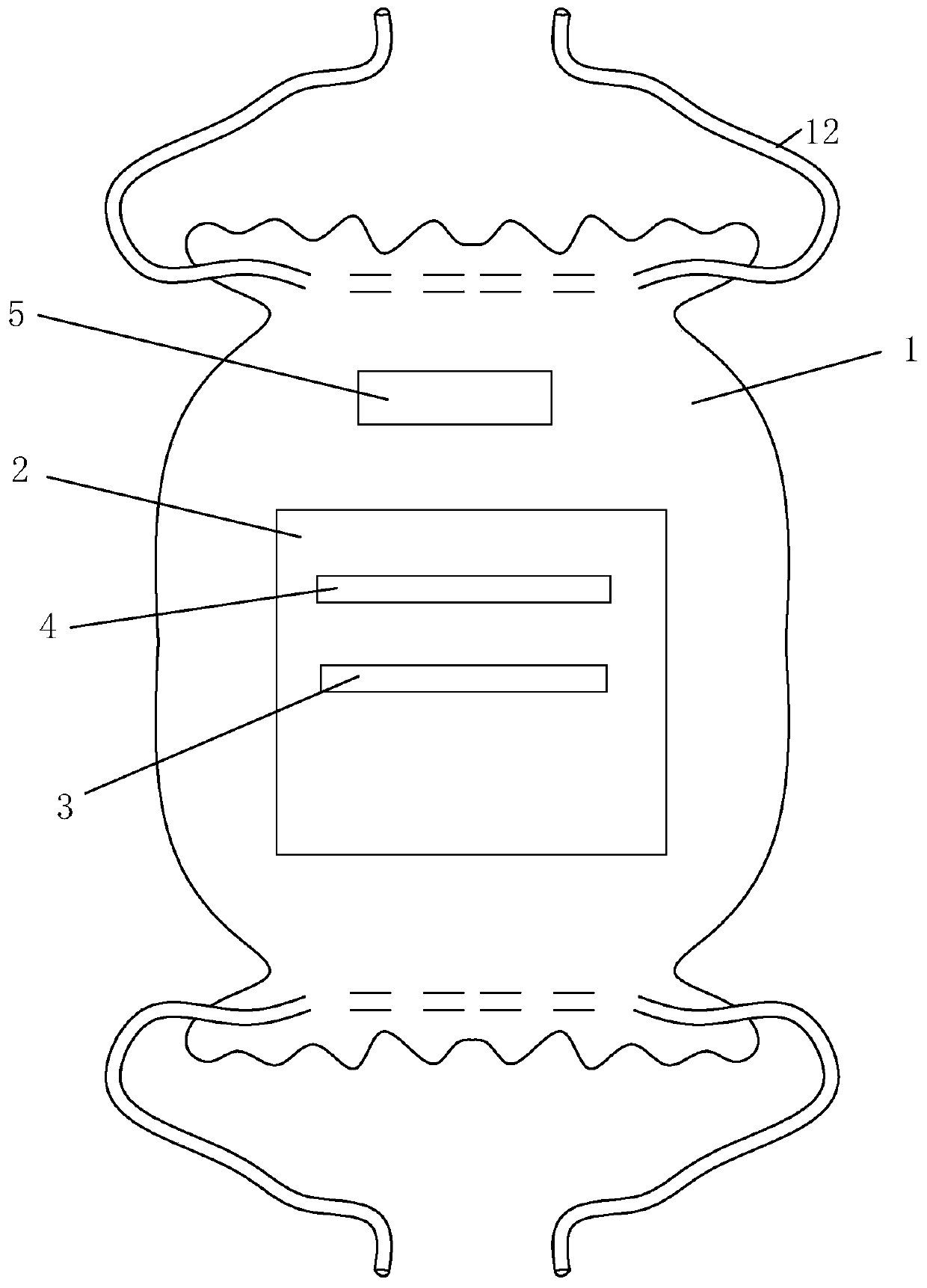

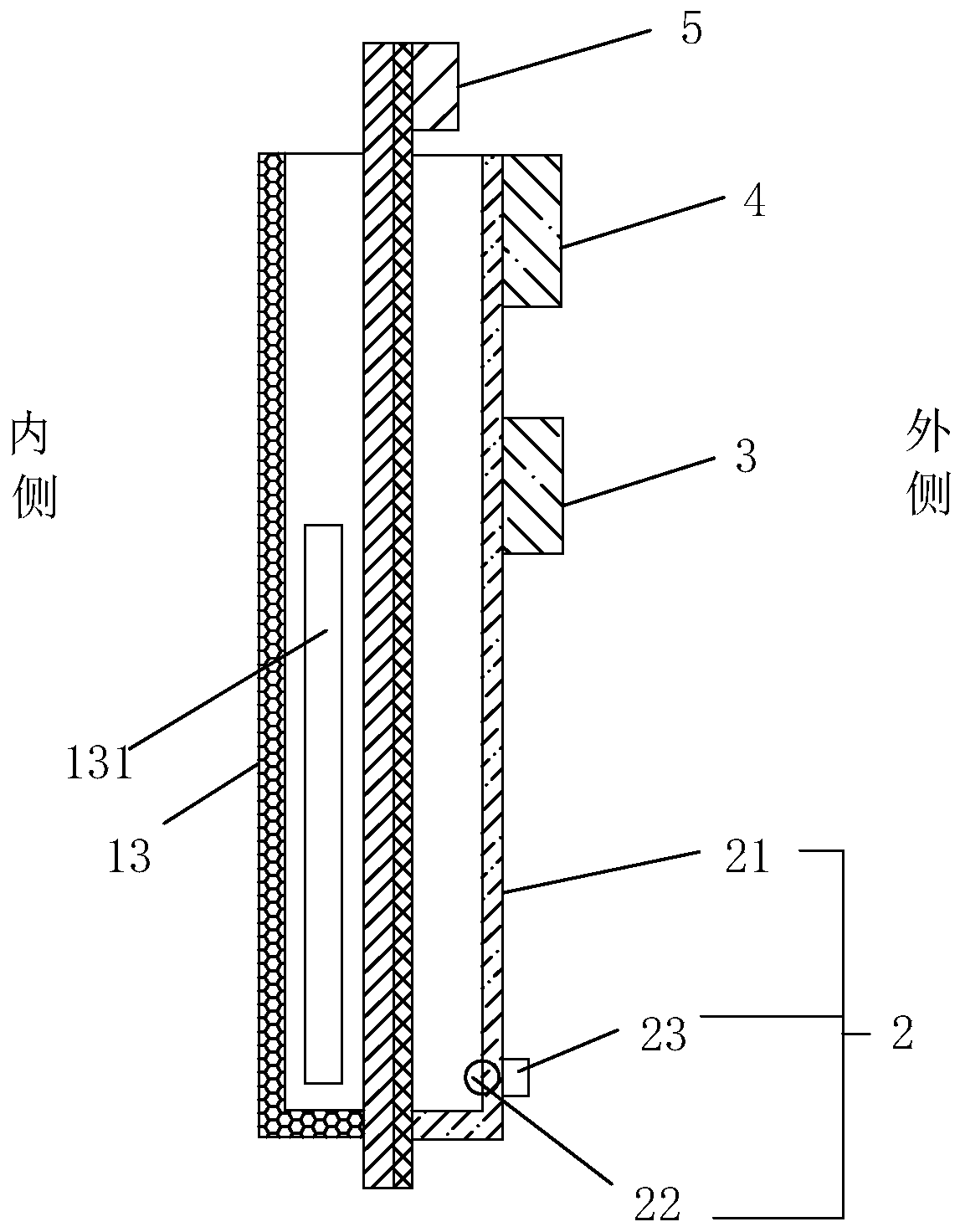

High-strength rope-pierced bag

A high-strength, rope bag technology, applied in the field of rope bags, can solve the problems of weak comprehensive function, tearing of packaging bags, perishable food, etc., and achieve improved preservation effect, strong impact resistance, and high structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A high-strength string-through bag, comprising the following raw materials in parts by weight: 120-140 parts of polypropylene resin, 5-10 parts of ethylene copolymer elastomer, 4-8 parts of butanetriol, 6-10 parts of acrylic emulsion, and 2 parts of kaolin -5 parts, 10-15 parts of polyvinyl alcohol, 25-50 parts of starch, 0.1-0.5 parts of antioxidant, 12-20 parts of calcium carbonate, 3-6 parts of paraffin, 15-20 parts of far-infrared emitting powder, nano silver powder 5-10 parts, 3-5 parts of flax fiber, 0.5-1.5 parts of silane coupling agent.

[0023] As a specific scheme of the present invention, it can be preferably: 125 parts of polypropylene resin, 6 parts of ethylene copolymer elastomer, 5 parts of butanetriol, 7 parts of acrylic acid emulsion, 2 parts of kaolin, 12 parts of polyvinyl alcohol, 30 parts of starch, 0.2 parts of oxygen agent, 15 parts of calcium carbonate, 3 parts of paraffin, 18 parts of far-infrared emitting powder, 6 parts of nano-silver powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com