Bioreactor for high-density large-scale animal cell culture and application thereof

A technology for animal cell culture and bioreactor, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, animal cells, etc., and can solve the problem of low mass transfer efficiency, complicated operation and complex structure problems, to achieve the effect of improving gas content and mass transfer coefficient, reducing cost, simplifying process and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

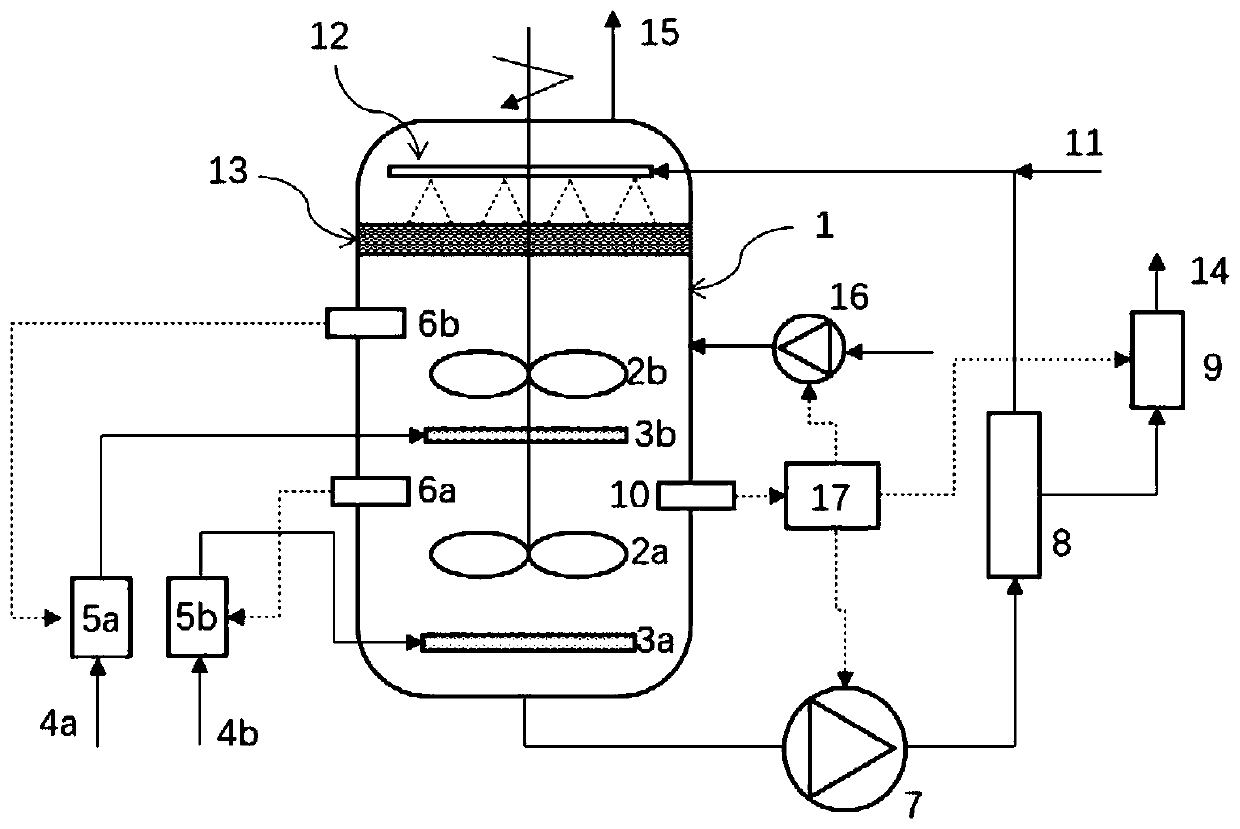

[0040] The structure of a bioreactor for high-density large-scale animal cell culture of the present invention is as follows: figure 1 As shown, it includes a reactor tank 1, a microporous aeration device 3, a dissolved oxygen electrode 6, a liquid circulation pump 7, a selective gas permeable membrane device 8, a spray device 12 and a defoaming device 13, wherein, in the reactor One or more axially propelling stirring paddles 2a and 2b are installed in the tank body 1 to promote the overall circulating flow of the liquid in the reactor. The air inlets of the aeration devices 3a and 3b are connected to the air sources 4a and 4b through the flow controllers 5a and 5b, and the dissolved oxygen electrodes 6a and 6b are installed in the reactor tank 1 to measure the dissolved oxygen concentration in the reactor. , and the dissolved oxygen electrodes 6a and 6b are respectively connected with the flow controllers 5a and 5b, and the flow controllers 5a and 5b can be controlled respec...

Embodiment 2

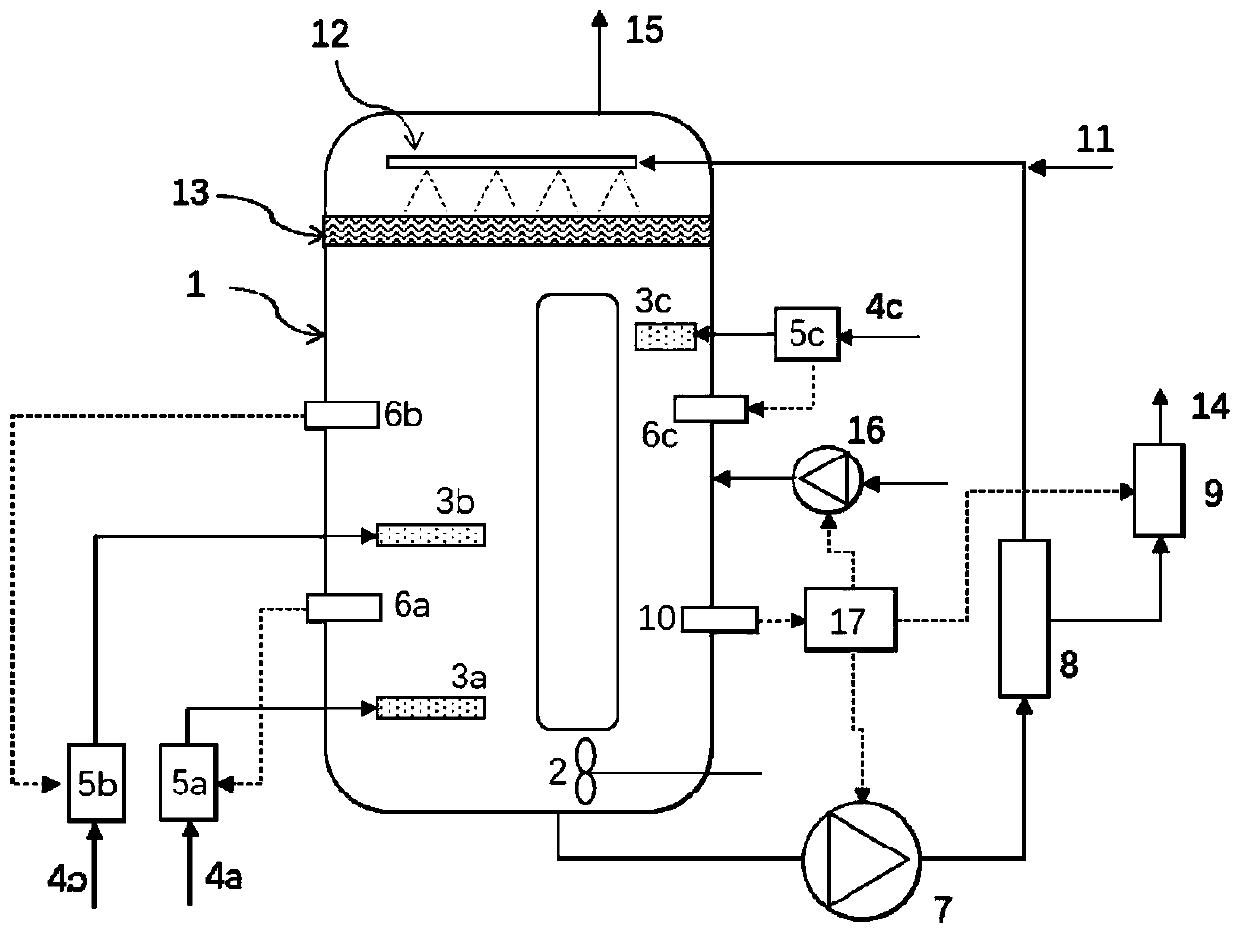

[0050] Another structure of a bioreactor for high-density large-scale animal cell culture of the present invention is as follows: image 3As shown, it includes a reactor tank 1, a microporous aeration device 3, a dissolved oxygen electrode 6, a liquid circulation pump 7, a selective gas permeable membrane device 8, a spray device 12 and a defoamer device 13, wherein the reaction The reactor tank 1 is an outer loop air-lift reactor with forced circulation, and the reactor tank 1 is a "return"-shaped reaction tank, wherein a circulating pump 2 is installed at the communicating place on both sides of the reaction tank, which is used for the reaction tank. The culture medium is forced to circulate to achieve the purpose of mixing; three microporous aeration devices 3a, 3b and 3c are installed on both sides of the "back" shaped reaction tank, and the air inlets of the microporous aeration devices 3a, 3b and 3c pass through The flow controllers 5a, 5b and 5c are connected to the gas...

Embodiment 3

[0052] use as image 3 The external circulation air-lift reactor is shown to cultivate Chinese hamster ovary cells, the inner diameter of one side is 6m, the gas and liquid on this side move upward, hereinafter referred to as the riser; the inner diameter of the other side is 1.9m, which measures gas and liquid. Both move downward, hereinafter referred to as the descending tube. The liquid level height is 10m and the working volume is 310m 3 . A 100kW axial-flow pump with a flow rate of 12,000m is installed at the lower connection of the riser and the descender. 3 / h, the head is 3m. A two-stage sintered stainless steel particle gas distributor is installed in the rising pipe, and the distance in the vertical direction is 3m. Both stages are concentric annular structures with an outer diameter of 5cm and a hole diameter of 0.02mm. The total aeration area of the lower gas distributor is 10m 2 , the maximum air flow is 1800Nm 3 / h; the total aeration area of the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com