Low-temperature cellulose degrading bacterium

A technology of cellulose degradation and low temperature, applied in the field of microorganisms, can solve the problems of adverse effects on the next crops and the inability to quickly and thoroughly decompose straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the examples, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention within the scope of protection.

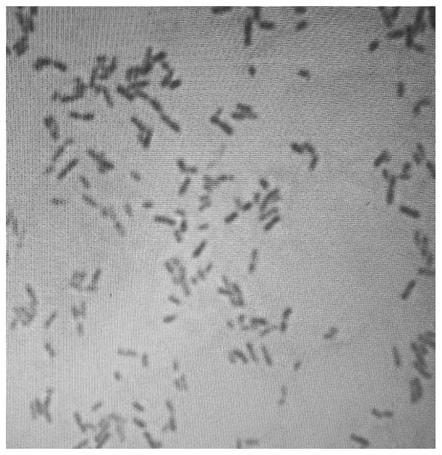

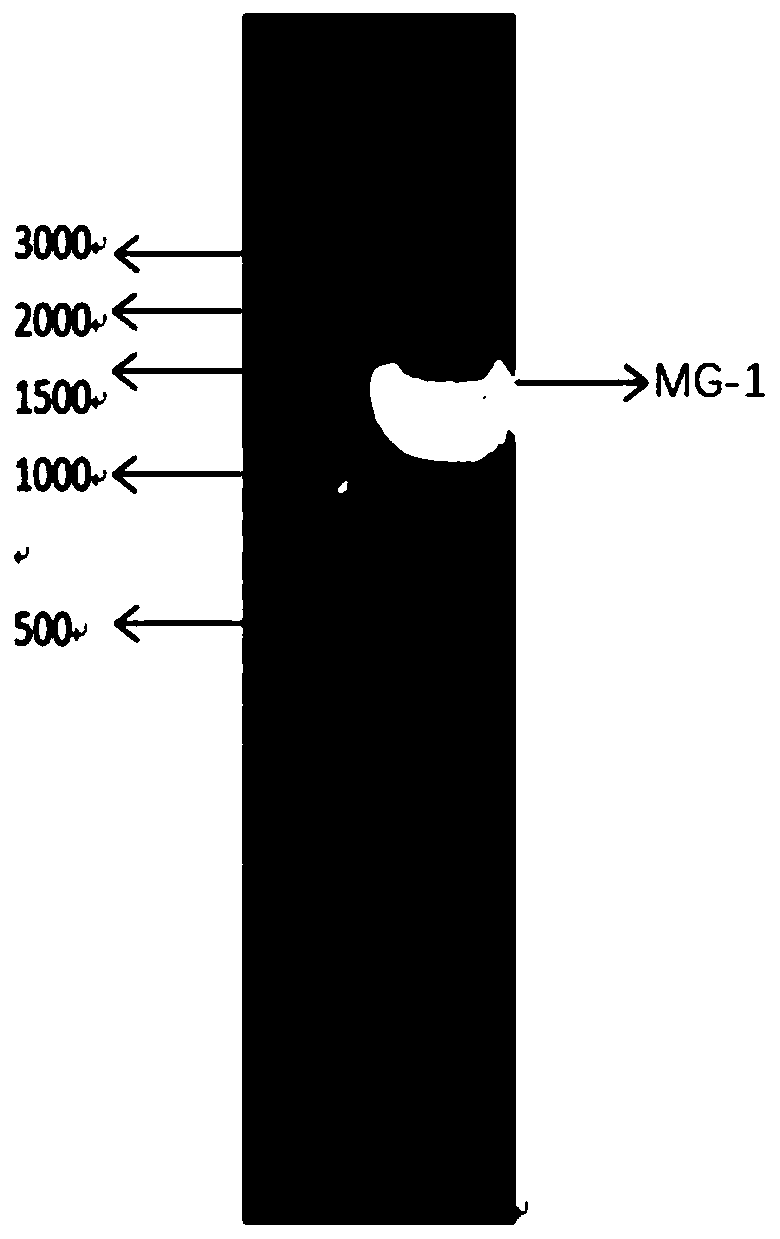

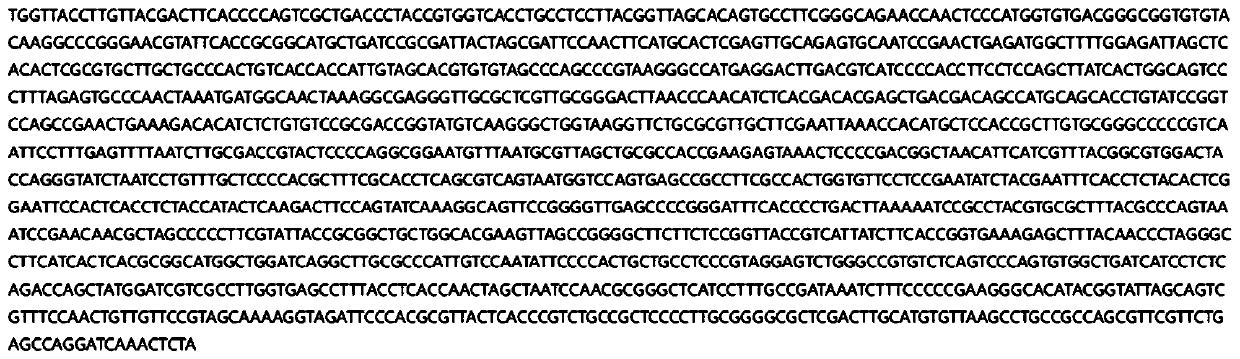

[0025] The invention provides a low-temperature cellulose-degrading bacterium, the specific content of which is as follows:

[0026] Medium used:

[0027] Enrichment medium (Hutchinson straw medium): KH 2 PO 4 1.0g, NaCl 0.1g, FeCl 3 ·6H 2 O0.01g, MgSO 4 ·7H 2 O 0.3g, NaNO 3 2.5g, CaCl 2 ·6H 2 O 0.1g, dilute to 1L with distilled water, add about 1.0g corn stalks per 100mL medium as the sole carbon source. The pretreatment method of the straw section is as follows: soak the straw section with a length of about 3 cm in distilled water overnight to remove so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com