Method for forming overlying crust on surface of dredging silt slurry storage yard and overlying crust

A technology of silt slurry and hard shell layer, which is applied in the field of foundation treatment, which can solve the problems of low degree of mechanization, large consumption of curing agent, and slow construction speed, and achieve the effects of improving construction efficiency, shortening construction period, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

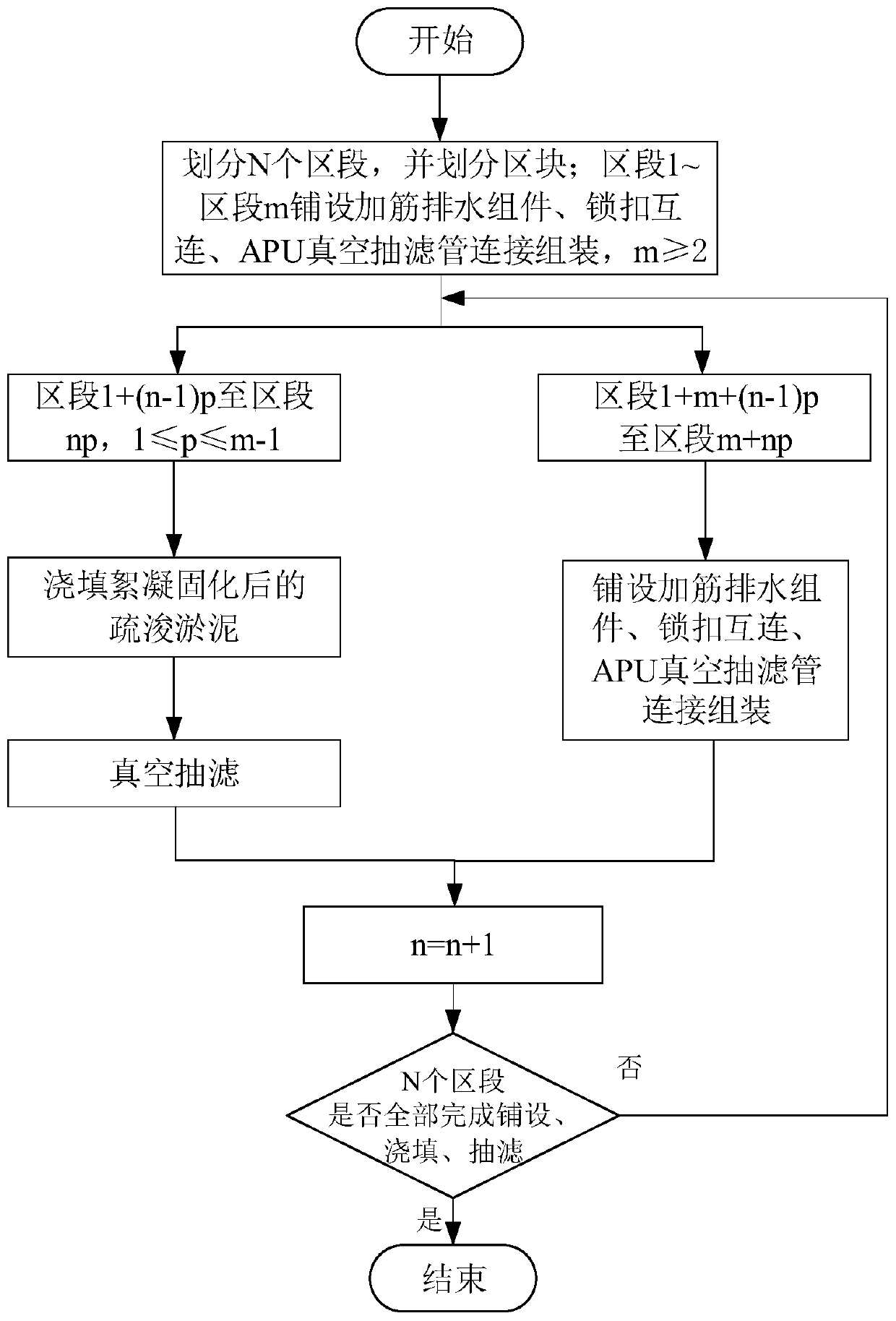

[0047] [Example 1] m=2, p=1

[0048] (1) Use a pumping device to pump the dredged sludge with a moisture content of up to 500% to the combined flocculation and solidification treatment unit for uniform stirring at a stirring speed between 60r / min and 120r / min until the flocculation and solidification process is completed; The work can be done ahead of time or during the sectioning and laying process.

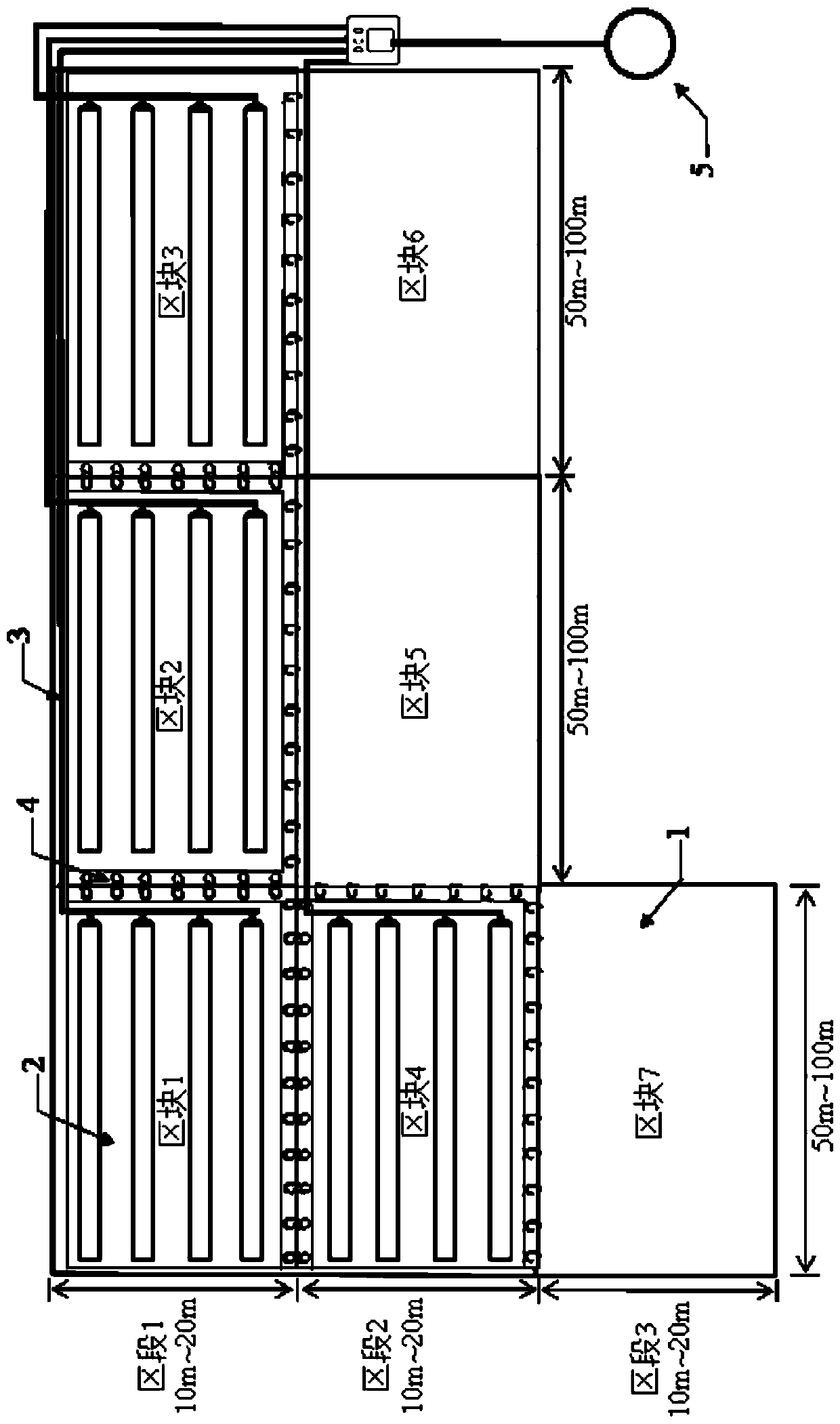

[0049] Divide the silt yard to be treated into N sections (the length of the section is directly determined by the size of the yard, with a width of 10m-20m), and each section is divided into multiple blocks (50m-100m in length and 10m-20m in width);

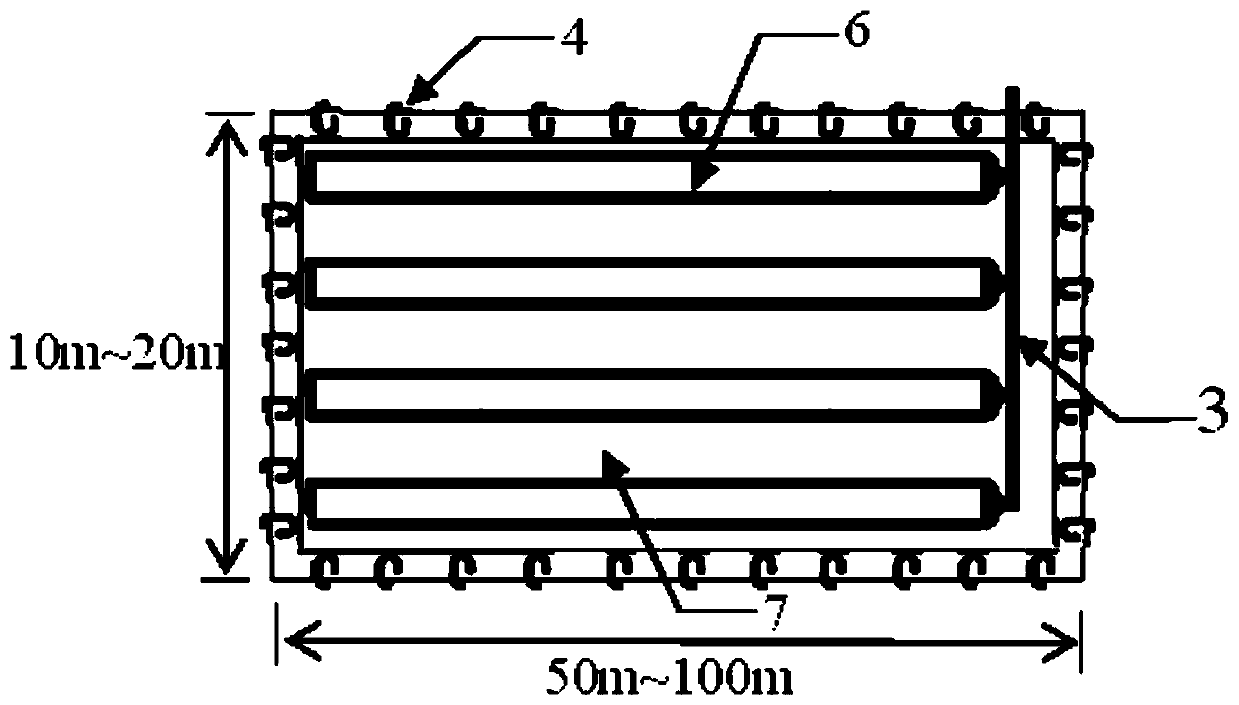

[0050] In this embodiment, m=2, p=1, that is, the prefabricated geotextile-plastic drainage board reinforced drainage assembly 2 is laid successively on each block of the yard section 1 and section 2, and the reinforcement is completed. Drainage assembly 2 is made up of geotextile 7-horizontal drainage board 6-geotextile 7 from t...

Embodiment 2

[0058] [Example 2] m=3, p=2

[0059] The difference between this embodiment and embodiment 1 is that two sections are poured at one time, and the delay between pouring and laying is still one section.

[0060] The operation table of the present embodiment is as shown in table 2:

[0061] Table 2 The process table when m=3, p=2

[0062]

[0063] In this embodiment, when the flocculated and solidified sludge from section 2n-1 to section 2n is poured, the section 2n+1 has completed the laying of reinforced drainage components, the assembly of vacuum filtration pipes, and the construction of adjacent areas. At this time, the laying of reinforced drainage components in section 2n+2 to section 2n+3, the assembly of vacuum filtration pipes and the locking of reinforced drainage components in adjacent blocks are being carried out. Button stitching work.

Embodiment 3

[0064] [Example 3] m=4, p=2

[0065] The difference between this embodiment and Embodiment 1 is that two sections are poured at one time, and the delay between pouring and laying is two sections.

[0066] The operation table of the present embodiment is as shown in table 3:

[0067] Table 3 Process table when m=4, p=2

[0068]

[0069] In this embodiment, when the flocculated and solidified sludge in section 2n-1 to section 2n is poured, the laying of reinforced drainage components and vacuum filtration pipelines in section 2n+1 to section 2n+2 have been completed. The assembly of the reinforced drainage components in the adjacent blocks and the locking and splicing of the reinforced drainage components in the adjacent blocks are being carried out. Locking splice work for reinforced drainage components.

[0070] Other data combination schemes for m and p can be directly deduced from the general term formula of the present invention and the above-mentioned embodiments, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com