Liquid medium superlens for aberration elimination

A liquid medium, metalens technology, applied in lenses, optics, instruments, etc., can solve the problems of inability to overcome imaging difficulties in the same way, troubled flat single metalens, large and high-order aberrations, etc., to avoid abnormal spatial arrangement. , eliminate technical bottlenecks, eliminate the effect of high-order aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

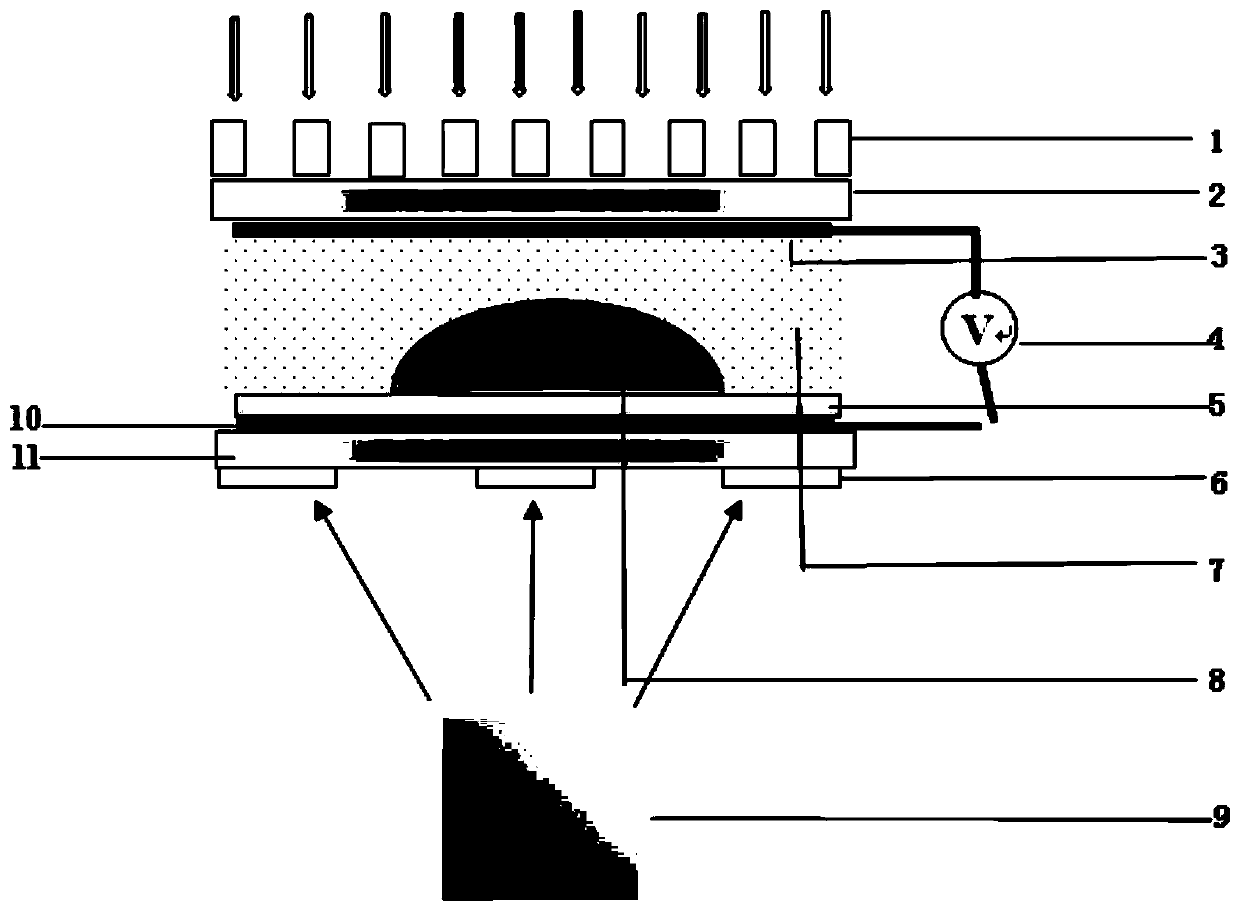

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Taking the elimination of the aberration produced by the traditional single-layer symmetric metalens as an example, an aberration-eliminating liquid medium metalens is implemented as follows.

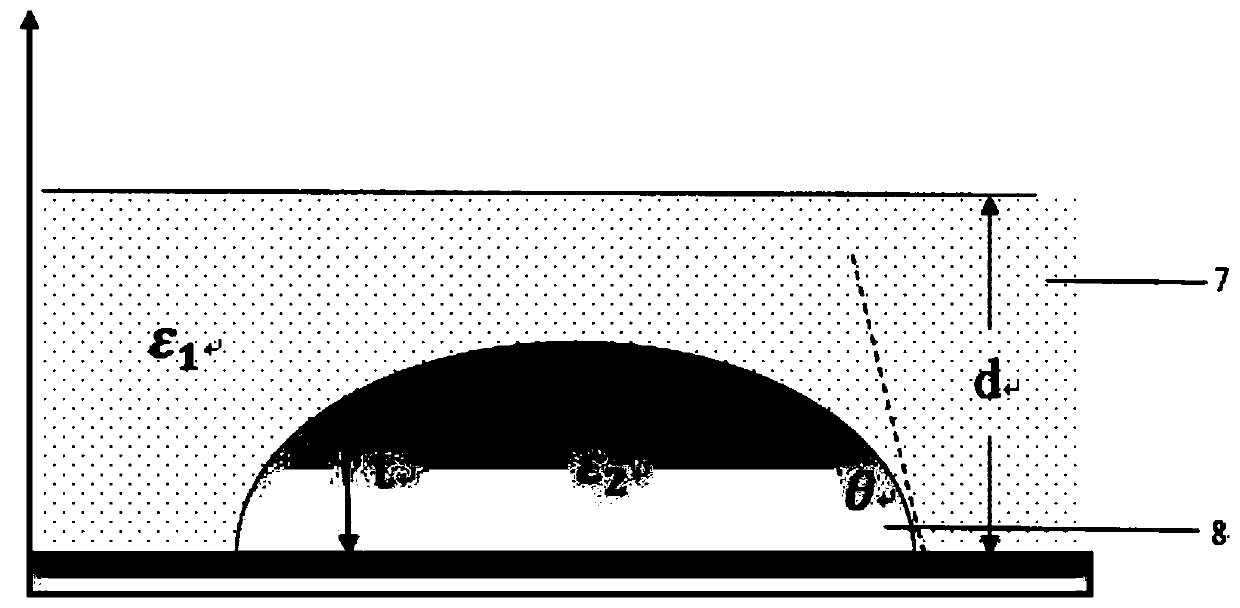

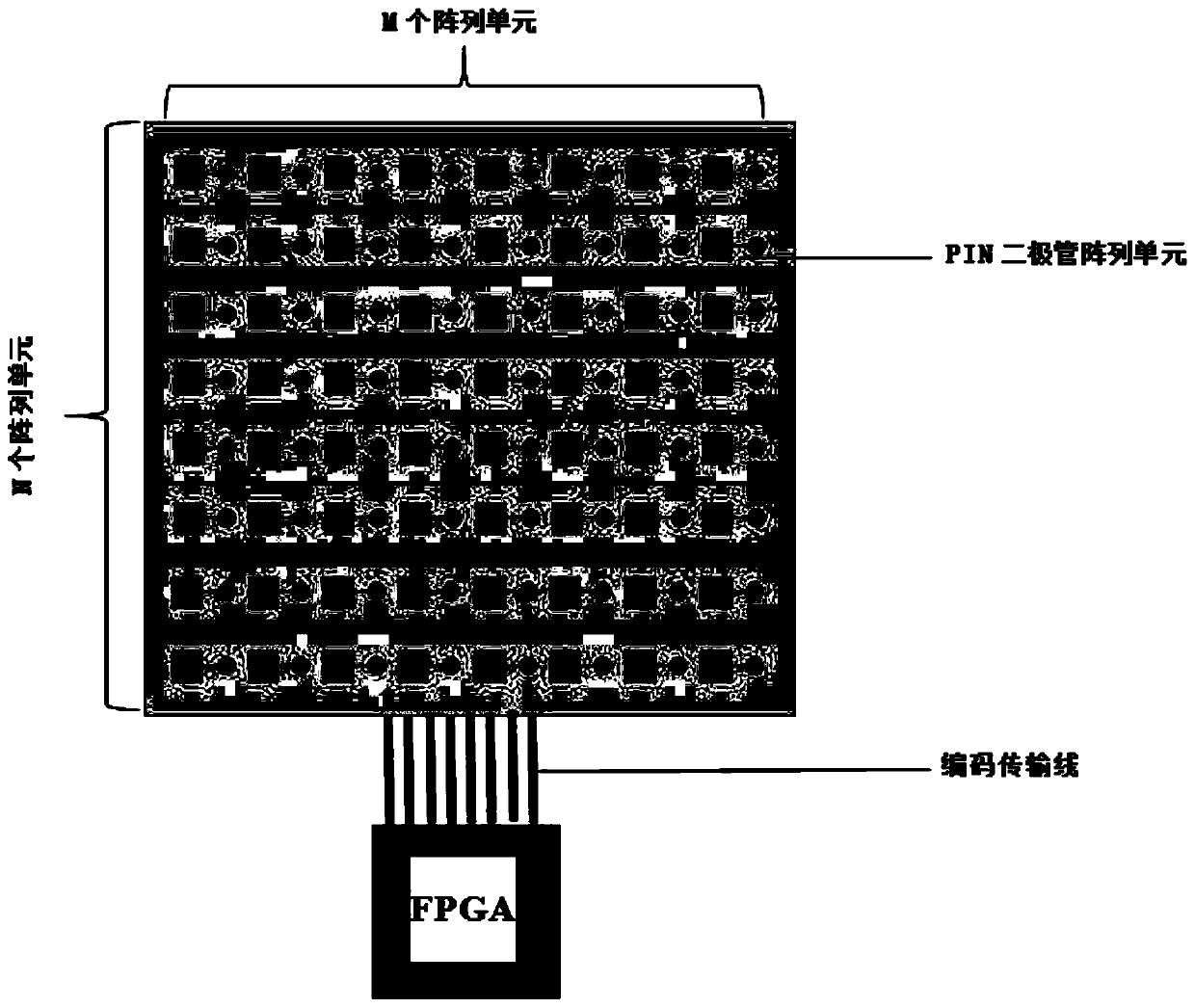

[0031] Such as figure 1 As shown, an aberration-eliminating liquid medium metalens includes an upper layer metasurface array, an upper layer metalens quartz substrate, a polymer layer, a lower layer metalens quartz substrate, and a lower layer metasurface array arranged in sequence from top to bottom.

[0032] The upper and lower metasurface arrays are respectively located on both sides of the core gap layer, and are attached to the upper and lower metalens quartz substrates. The upper and lower superlens quartz substrates are coated with a layer of ITO conductive thin film (indium tin oxide, indium tin oxide layer) on the side close to the core gap layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com