Sodium alginate microsphere filling material and preparation method thereof

A filling material, sodium alginate technology, applied in the field of biomedicine, can solve the problems of high biotoxicity of cross-linking agents, injection beauty hazards, etc., and achieve the effect of facilitating industrial production, overcoming biotoxicity, and good shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

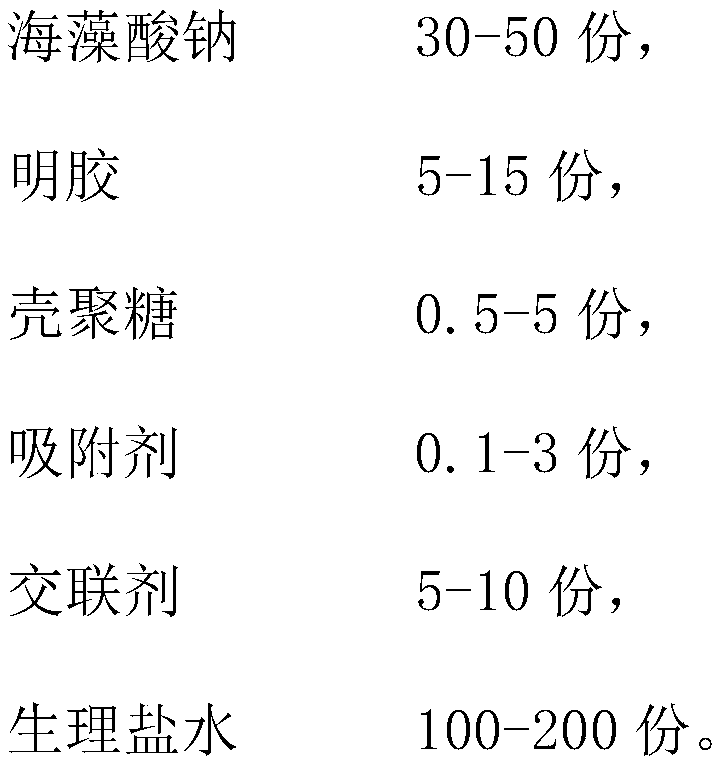

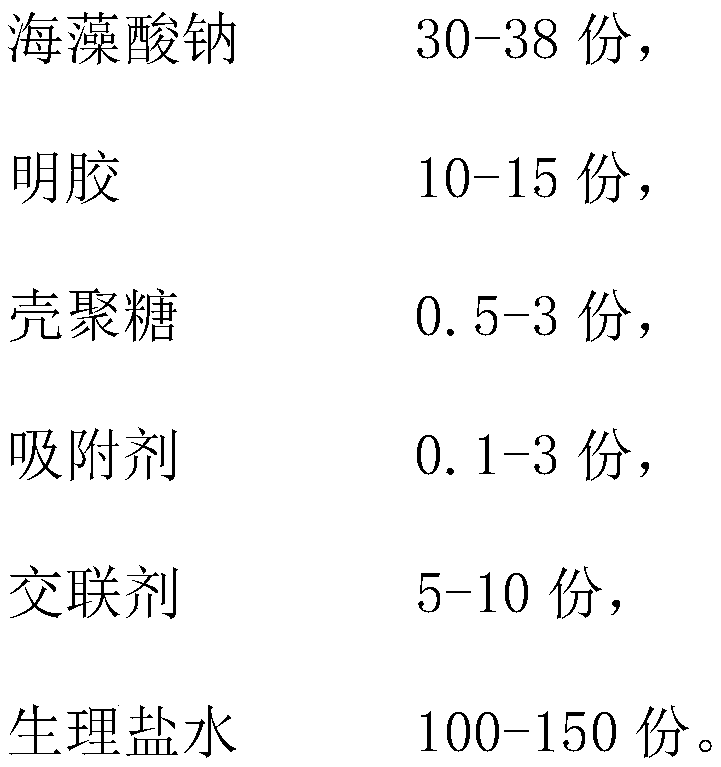

Method used

Image

Examples

Embodiment 1

[0033] A sodium alginate microsphere filling material, the filling material is made of raw materials comprising the following parts by weight: 32 parts of sodium alginate, 10 parts of gelatin, 0.6 part of chitosan, 0.2 part of carboxymethyl cellulose, collagen 5 parts protein, 120 parts normal saline, 10 parts polylactic acid.

[0034] The preparation method of the sodium alginate microsphere filling material comprises the following steps: (1) heating and melting the gelatin, adding chitosan therein, and mixing uniformly under stirring at 3000-5000rpm to obtain a premix; (2) mixing Sodium alginate, adsorbent and cross-linking agent were dissolved in physiological saline, and mixed uniformly to obtain a filling solution; (3) adding the premixed solution into liquid paraffin containing 1% Tween 80, stirring and emulsifying for 30 minutes, To obtain a pre-mixed emulsion, add the filling solution to liquid paraffin containing 1% Tween 80, stir and emulsify for 30 minutes to obtain...

Embodiment 2

[0037] A sodium alginate microsphere filling material, the filling material is made of raw materials comprising the following parts by weight: 32 parts of sodium alginate, 15 parts of gelatin, 0.6 part of chitosan, 0.2 part of carboxymethyl cellulose, collagen 5 parts protein, 120 parts normal saline, 10 parts polylactic acid.

[0038] The preparation method of the sodium alginate microsphere filling material comprises the following steps: (1) heating and melting the gelatin, adding chitosan therein, and mixing uniformly under stirring at 3000-5000rpm to obtain a premix; (2) mixing Sodium alginate, adsorbent and cross-linking agent were dissolved in physiological saline, and mixed uniformly to obtain a filling solution; (3) adding the premixed solution into liquid paraffin containing 1% Tween 80, stirring and emulsifying for 30 minutes, To obtain a pre-mixed emulsion, add the filling solution to liquid paraffin containing 1% Tween 80, stir and emulsify for 30 minutes to obtain...

Embodiment 3

[0041] A sodium alginate microsphere filling material, the filling material is made of raw materials comprising the following parts by weight: 32 parts of sodium alginate, 15 parts of gelatin, 3 parts of chitosan, 0.2 part of carboxymethyl cellulose, collagen 5 parts protein, 120 parts normal saline, 10 parts polylactic acid.

[0042] The preparation method of the sodium alginate microsphere filling material comprises the following steps: (1) heating and melting the gelatin, adding chitosan therein, and mixing uniformly under stirring at 3000-5000rpm to obtain a premix; (2) mixing Sodium alginate, adsorbent and cross-linking agent were dissolved in physiological saline, and mixed uniformly to obtain a filling solution; (3) adding the premixed solution into liquid paraffin containing 1% Tween 80, stirring and emulsifying for 30 minutes, To obtain a pre-mixed emulsion, add the filling solution to liquid paraffin containing 1% Tween 80, stir and emulsify for 30 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com