Method for mechanochemically degrading hexachlorobenzene by using silicon carbide as catalyst

A mechanochemical method, hexachlorobenzene technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high energy consumption and long hexachlorobenzene time, and reduce the degradation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

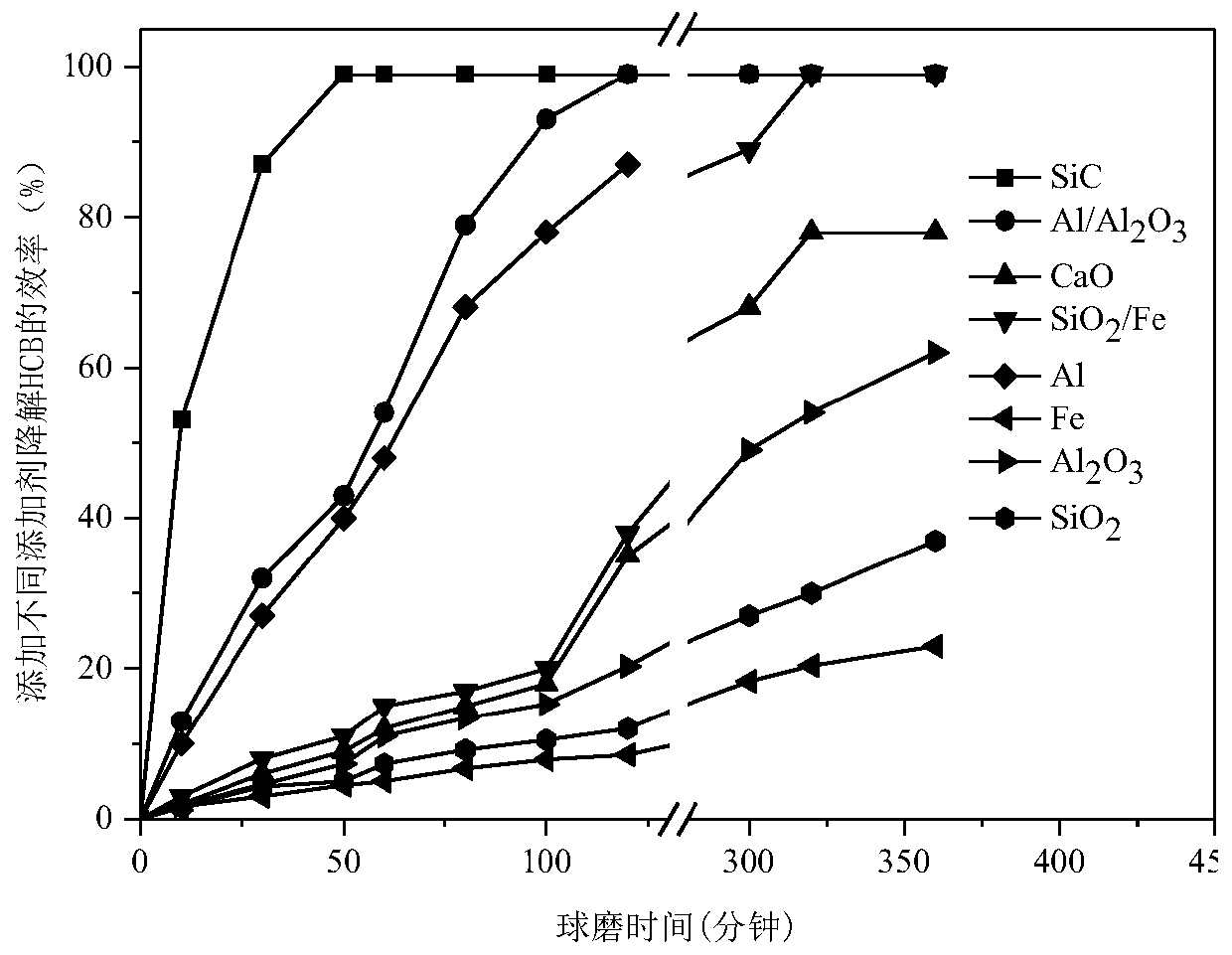

[0046] Various additives were applied to the experiments of mechanochemical degradation of HCB. Additives include metal oxides (CaO and Al 2 O 3), metals (Fe and Al), SiO 2 , additive combination (Fe+SiO 2 and Al / Al 2 O 3 ) and SiC. Among them, CaO, Al 2 O 3 , Fe, Al, SiO 2 , Fe+SiO 2 and Al+Al 2 O 3 It is to repeat the previous research. SiC is a new additive to be verified. At present, there is no report on the use of SiC ball milling to degrade HCB. In the experiment, the mass ratio of the additive added to the ball mill to HCB was 5:1, and the experimental process was to add the additive and HCB to the stainless steel sealed ball mill tank (0.5L) of the ball mill, and the mass ratio of the additive to HCB was 5:1 ( The mass of SiC is 2.5g, the particle size is 30 mesh; the mass of HCB is 0.5g), and the total mass of stainless steel grinding balls is 270g (diameter and number of grinding balls: 10 diameters 15mm; 25 diameters 8mm; 25 diameters 5mm), ball mill 1...

Embodiment 1

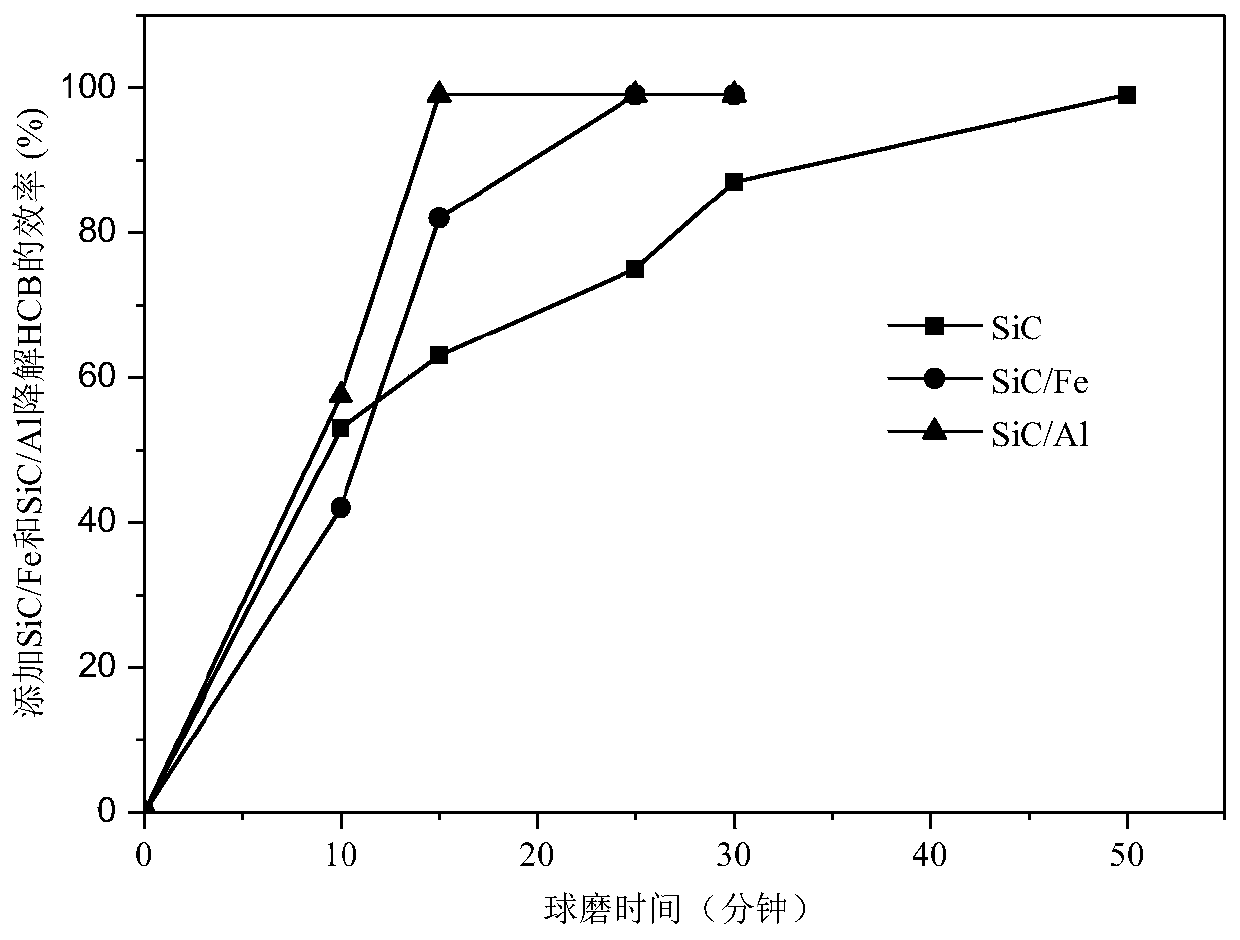

[0049] Using Fe powder and SiC as additives, Fe powder is 40% of the total mass of Fe powder and SiC, and Fe powder particle size is 200 meshes. Add additives and HCB to the stainless steel sealed ball mill tank (0.5L) of the ball mill. The mass ratio is 5:1 (the mass of SiC is 2.5g, the particle size is 30 meshes; the mass of HCB is 0.5g), and the total mass of stainless steel grinding balls is 270g (diameter and number of grinding balls: 10 pieces with a diameter of 15mm; 25 pieces with a diameter of 8mm; 25 pieces with a diameter of 5mm), revolution and rotation ratio of 1:2, rotation at 700r / min, ball milling for 10min, to detect the degradation efficiency of HCB, the results are as follows figure 2 shown.

Embodiment 2

[0051] This embodiment is the same as embodiment 1, the difference is: the ball milling time is 15min, and the result is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com