Method for preparing high-purity conjugated linoleate by using simulated moving bed

A technology of conjugated linoleate and conjugated ethyl linoleate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as the inability to prepare pure products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (1) Preparation of the raw material solution, dissolving the low-purity conjugated ethyl linoleate raw material in methanol (or ethanol) to prepare a raw material solution.

[0021] (2) The eluent can be ethanol / water, methanol / water, acetonitrile / water, etc., preferably methanol / water (80:20W / W).

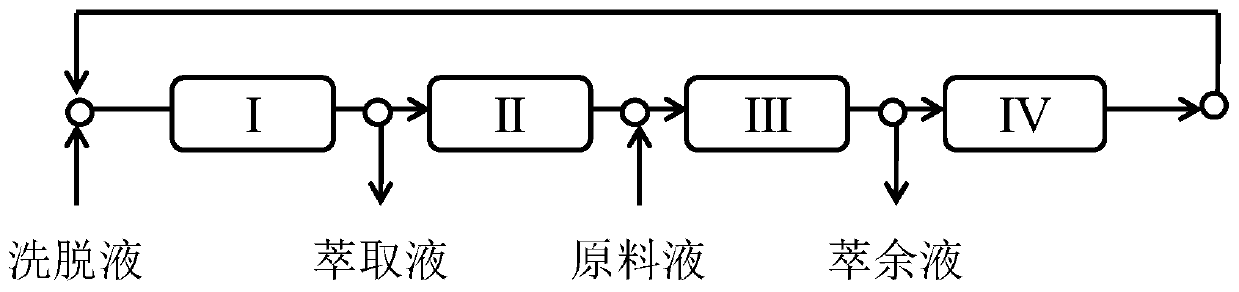

[0022] (3) The raw material liquid and eluent are continuously flowed into the simulated moving bed chromatography system, which is a four-zone simulated moving bed, with two chromatographic columns arranged in each zone, and the two chromatographic columns are both C18 silica gel columns, or C8 silica gel The chromatographic column and C18 silica gel are connected in series, the product is taken out from the extraction port, and the impurities are flowed out from the raffinate port. Set an appropriate switching time for separation and purification, see the specific process flow figure 2 .

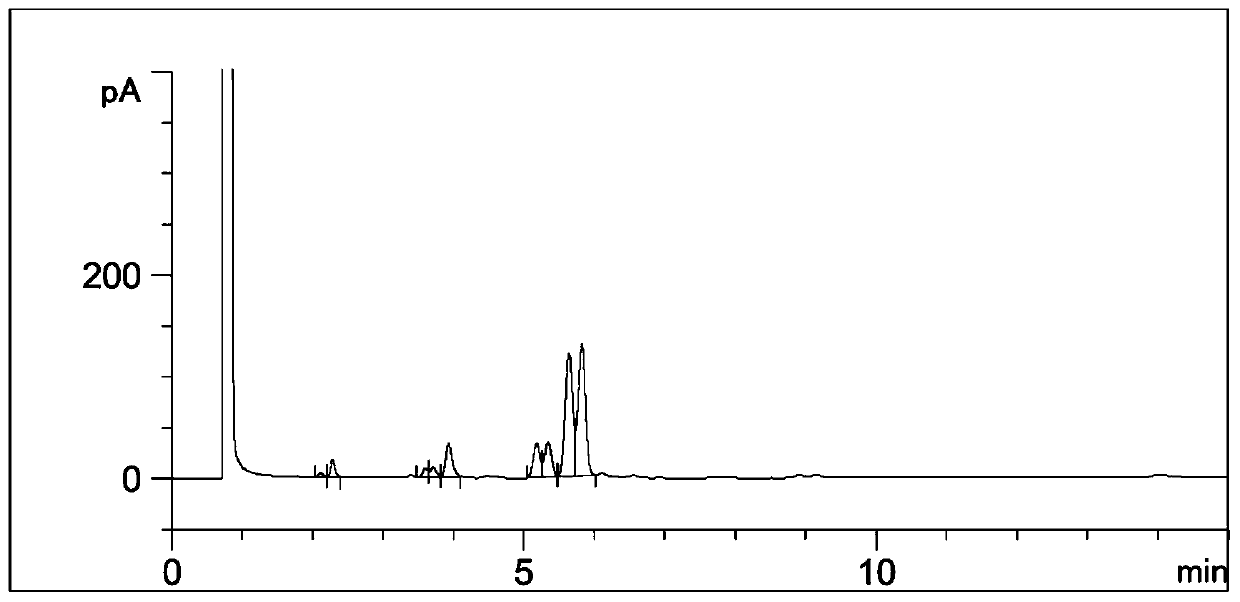

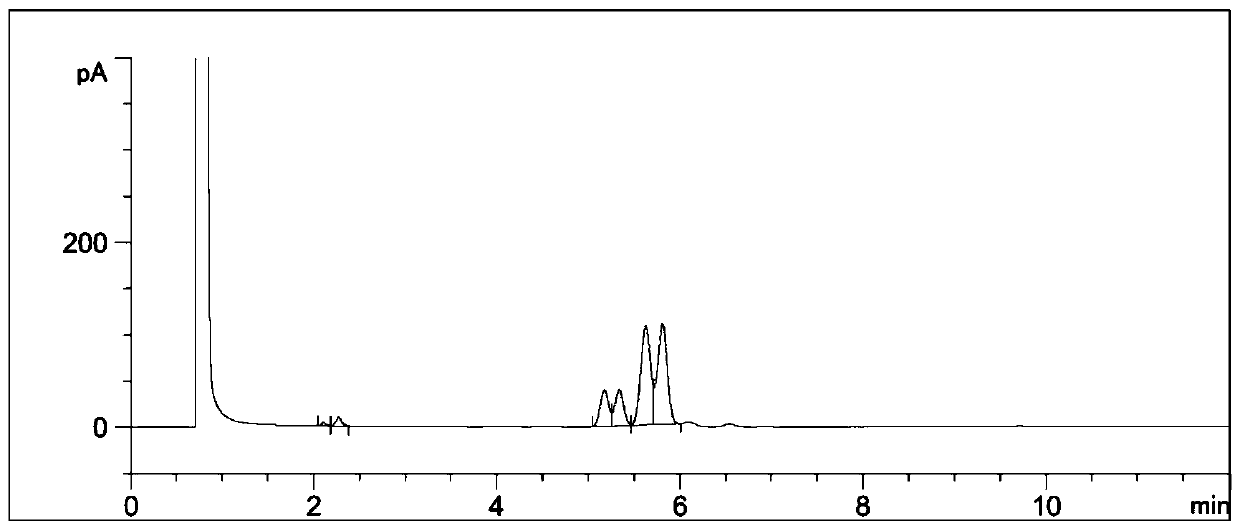

[0023] The purified conjugated ethyl linoleate was determined by gas chromatograp...

Embodiment 1

[0025] The preparation method of high-purity conjugated ethyl linoleate comprises the following steps:

[0026] For the preparation of the raw material injection solution, ethyl conjugated linoleate with a purity of 80.15% was dissolved in methanol to prepare a 25 mg / mL solution.

[0027] The eluent was methanol / water (80:20W / W).

[0028] The raw material liquid and eluent flow into the simulated moving bed chromatographic system continuously. The system is a four-zone simulated moving bed. Two chromatographic columns are arranged in each zone, and the two chromatographic columns are C18 silica gel chromatographic columns. The product is taken out from the extraction port, and Impurities flow out from the raffinate port. Set the switching time for 5 minutes, and the flow rate in the I-IV area is 3.8mL / min, 3.2mL / min, 3.5mL / min and 2.8mL / min in sequence for separation and purification.

[0029] Utilize gas chromatography to measure the content of conjugated ethyl linoleate af...

Embodiment 2

[0031] The preparation method of high-purity conjugated ethyl linoleate comprises the following steps:

[0032] For the preparation of the raw material injection solution, ethyl conjugated linoleate with a purity of 80.15% was dissolved in methanol to prepare a 25 mg / mL solution.

[0033] The eluent was methanol / water (80:20W / W).

[0034] The raw material liquid and the eluent are continuously flowed into the simulated moving bed chromatography system. The system is a four-zone simulated moving bed, and two chromatographic columns are arranged in each zone. The two chromatographic columns are a C8 silica gel column and a C18 silica gel in series. The product is taken out from the extraction port (Extract), while the impurities flow out from the raffinate port (Raffinate). Set the switching time to 5.2min, and the flow rate in the I-IV area is 3.6mL / min, 3.1mL / min, 3.3mL / min and 2.5mL / min in sequence, for separation and purification.

[0035] Utilize gas chromatography to mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com