A kind of preparation method of impurity w in cisatracurium besylate

A technology of cisatracurium besylate and impurities, which is applied in the field of impurities in cisatracurium besylate and cisatracurium besylate, which can solve the difficulty of impurity W, unclear efficacy and side effects, etc. problem, to achieve the effect of simple preparation method, high purity, and promotion of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

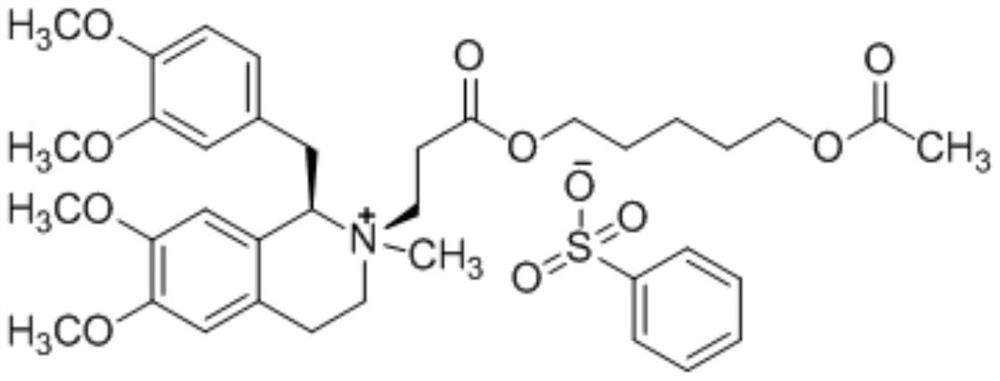

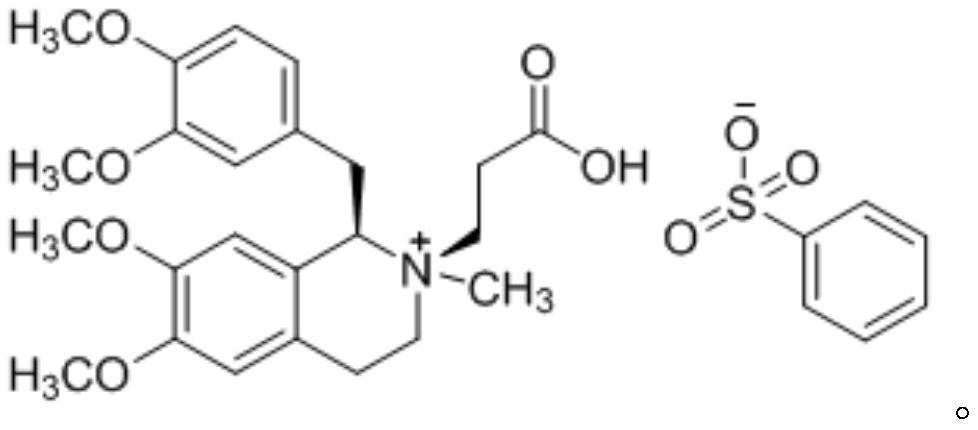

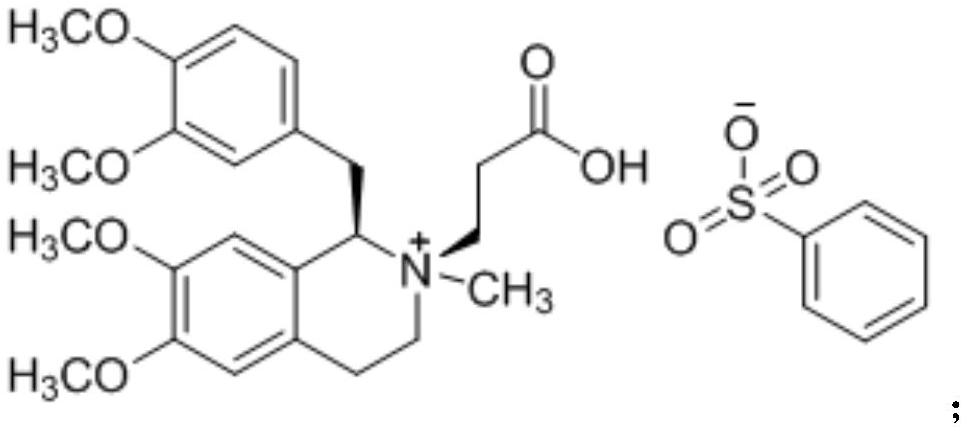

[0030] A kind of preparation method of impurity W in cisatracurium besylate, the structure of impurity W is as shown in formula (I),

[0031] Formula (I):

[0032] The preparation method of impurity W comprises the steps:

[0033] A. Get 1,5-pentanediol, glacial acetic acid, and catalyst to react to obtain a reaction solution; wherein the catalyst is p-toluenesulfonic acid, and the molar ratio of 1,5-pentanediol, glacial acetic acid and catalyst is 1: 1.4~1.6:0.4~0.6; During the reaction process, continuously feed boiling n-hexane into the reaction system (for example, n-hexane can be heated to 70-80°C) to reflux and divide water (the boiling n-hexane enters the reaction system to During the process of external circulation of the system, the water generated in the reaction system will be taken out to promote the positive progress of the reaction. When the n-hexane with water is discharged from the system, the water will be removed through the liquid separator first, and the...

Embodiment 1

[0046] A kind of preparation method of impurity W in cisatracurium besylate, the structure of impurity W is as shown in formula (I),

[0047] Formula (I):

[0048] The preparation method of impurity W comprises the steps:

[0049] A. Get 1,5-pentanediol, glacial acetic acid, and catalyst to react to obtain a reaction solution; wherein the catalyst is p-toluenesulfonic acid, and the molar ratio of 1,5-pentanediol, glacial acetic acid and catalyst is 1: 1.4:0.4; During the reaction process, continuously feed boiling n-hexane into the reaction system (for example, the n-hexane can be heated to 70°C) for reflux and water separation. After the reaction is completed, the boiling n-hexane is discharged from the system and no longer enters Reaction system, thereby abandoning n-hexane;

[0050] B. Add the mixed solution of water and n-hexane to the reaction solution, leave to stand for layering after stirring for liquid separation, discard the n-hexane layer solution, and collect t...

Embodiment 2

[0057] A kind of preparation method of impurity W in cisatracurium besylate, the structure of impurity W is as shown in formula (I),

[0058] Formula (I):

[0059] The preparation method of impurity W comprises the steps:

[0060] A. Get 1,5-pentanediol, glacial acetic acid, catalyzer to react, obtain reaction liquid; Wherein catalyzer is p-toluenesulfonic acid, the mol ratio of 1,5-pentanediol, glacial acetic acid and catalyzer is 1: 1.6:0.6; During the reaction process, continuously feed boiling n-hexane into the reaction system (for example, the n-hexane can be heated to 80°C) for reflux and water separation. After the reaction is completed, the boiling n-hexane is discharged from the system and no longer enters Reaction system, thereby abandoning n-hexane;

[0061] B. Add the mixed solution of water and n-hexane to the reaction solution, leave to stand for layering after stirring for liquid separation, discard the n-hexane layer solution, and collect the water layer so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com