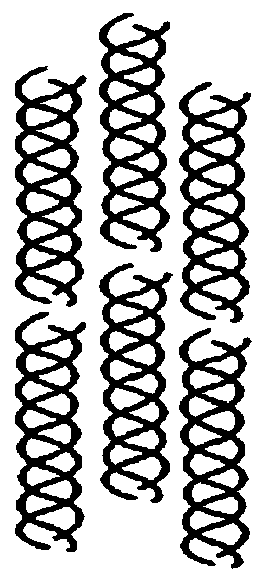

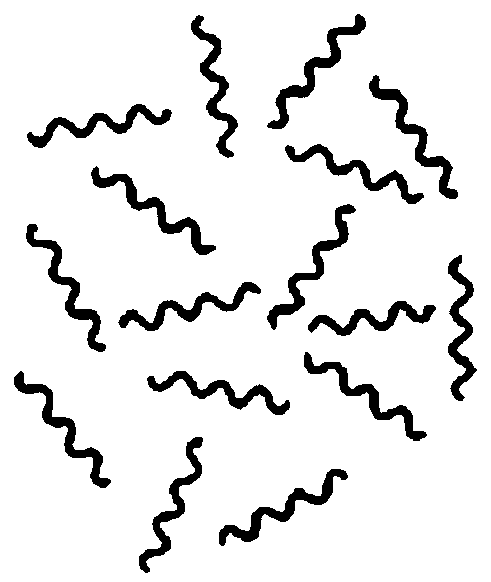

Curdlan gum purification method and application

A purification method and technology of alkaline solution, applied in the field of industrialized production of keratin, can solve the problems of unsatisfactory purity and gel strength, ineffective enzyme preparation, poor separation effect, etc., to achieve comparable appearance transparency and reduce processing capacity The effect of reducing production equipment cost and viscosity reduction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

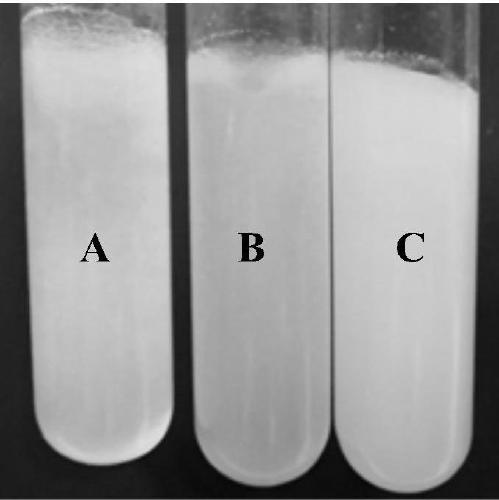

Examples

Embodiment 1

[0039] A high-efficiency sterilization method for microbial polysaccharide curdlan gum fermentation broth, the specific process steps are as follows:

[0040] (1) Dilute alkali solution

[0041] Add curdlan gum fermentation liquid in sodium hydroxide solution, constantly stir and make it dissolve completely, control the concentration of curdlan gum in the solution to be 1.6% (w / v), [OH - ] The concentration is 0.35mol / L. After the dissolution is completed, the initial viscosity of the solution is 1500mPa.s.

[0042] (2) High shear quickly reduces viscosity

[0043] After the dilution and alkali dissolution is completed, the curdlan gum solution is treated at a shear rate of 5000r / min for 6 minutes to reduce the viscosity rapidly to facilitate subsequent filtration and sterilization. After the treatment, the viscosity of the curdlan gum solution drops to 31mPa.s.

[0044] (3) Sterilization by filtration

[0045] The curdlan alkali solution whose viscosity is reduced in step...

Embodiment 2

[0055] A high-efficiency sterilization method for microbial polysaccharide curdlan gum fermentation broth, the specific process steps are as follows:

[0056] (1) Dilute alkali solution

[0057] Add curdlan gum fermentation liquid in sodium hydroxide solution, constantly stir and make it dissolve completely, control the concentration of curdlan gum in the solution to be 2.0% (w / v), [OH - ] The concentration is 0.50mol / L. After the dissolution is completed, the initial viscosity of the solution is 2300mPa.s.

[0058] (2) High shear quickly reduces viscosity

[0059] After the dilution and alkali dissolution is completed, the curdlan gum solution is treated at a shear rate of 7000r / min for 8 minutes to reduce its viscosity rapidly, so as to facilitate subsequent filtration and sterilization. After treatment, the viscosity of curdlan gum solution drops to 52mPa.s.

[0060] (3) Sterilization by filtration

[0061] The curdlan alkali solution whose viscosity is reduced in step ...

Embodiment 3

[0071] A kind of high-efficiency sterilization method of microbial polysaccharide curdlan gum crude product, its specific process steps are as follows:

[0072] (1) Dilute alkali solution

[0073] Add the aqueous suspension of curdlan thick product in the sodium hydroxide solution, constantly stir and make it dissolve completely, control the concentration of curdlan in the solution to be 2.3% (w / v), [OH - ] The concentration is 0.60mol / L. After the dissolution is completed, the initial viscosity of the solution is 2800mPa.s.

[0074] (2) High shear quickly reduces viscosity

[0075] After the dilution and alkali dissolution, the curdlan solution was treated at a shear rate of 8000r / min for 10 minutes to reduce its viscosity rapidly to facilitate subsequent filtration and sterilization. After treatment, the viscosity of the curdlan solution dropped to 66mPa.s.

[0076] (3) Sterilization by filtration

[0077] The curdlan alkali solution whose viscosity is reduced in step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com