Super-thick regenerative cement stabilized macadam foundation

A technology for stabilizing gravel base and reclaiming cement, applied in roads, roads, buildings, etc., can solve problems such as waste of machinery and personnel, increase road costs, strength damage, etc., and achieve high utilization, cost saving, and shortening of age. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

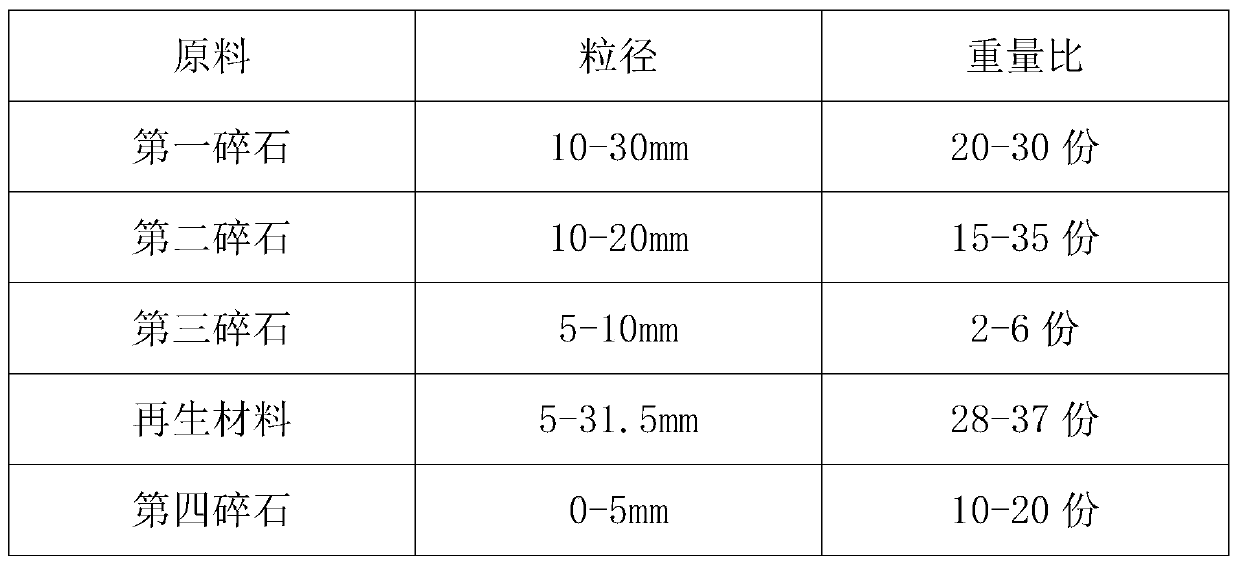

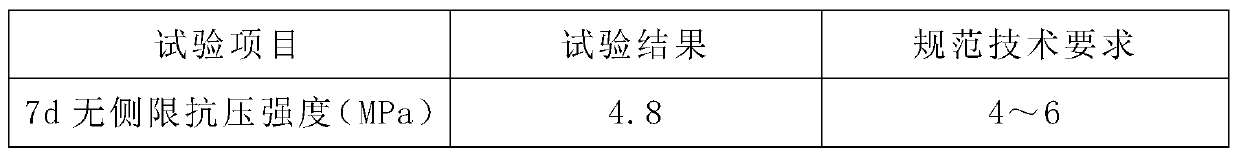

[0055] The ultra-thick recycled cement stabilized crushed stone base is composed of the following raw materials: the first crushed stone, the second crushed stone, the third crushed stone, recycled materials, and the fourth crushed stone; the weight ratio of the above raw materials is: the first crushed stone: The second crushed stone: the third crushed stone: recycled material: the fourth crushed stone=27 parts: 14 parts: 4 parts: 33 parts: 20 parts, the degree of compaction of the base layer is ≥ 96%, and the water content of the base layer 5.5%~6.3%, the dry density of the base layer is 2.0~2.4g / cm 3 .

Embodiment 2

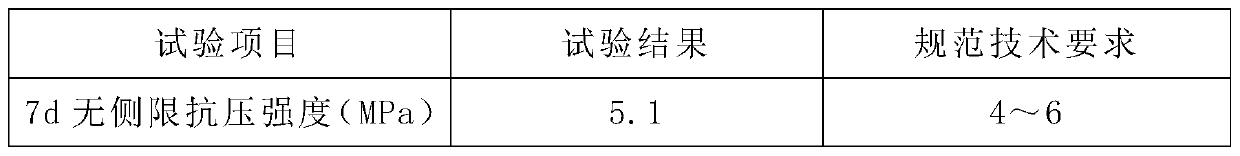

[0057] Ultra-thick recycled cement stabilized crushed stone base, composed of the following raw materials: first crushed stone: second crushed stone: third crushed stone: recycled material: fourth crushed stone = 23 parts: 30 parts: 3 parts: 29 parts: 14 share.

[0058] The degree of compaction of the base layer is ≥96%, the water content of the base layer is 6.1%, and the maximum dry density of the base layer is 2.298g / cm 3 .

Embodiment 3

[0060] In order to prepare an ultra-thick recycled cement-stabilized gravel base, the preparation process of the ultra-thick recycled cement-stabilized gravel base comprises the following steps:

[0061] 1) Demolition and milling of pavement, planing and milling of asphalt pavement with milling machine, oil hammer for cement concrete pavement, breaking water stabilization layer and fly ash layer with oil hammer, and concentrating water stabilization or fly ash with excavator pile up.

[0062] 2) Crushing and grading. After the old cement-stabilized gravel is sent to the crushing station, it is crushed by a conventional gravel crusher. The crushed cement-stabilized gravel is conveyed to the grading sieve for classification and screening through a belt to obtain recycled materials that meet the particle size requirements. Material.

[0063] 3) Design grading, carry out tests such as sieving the graded crushed stone, compacting the inorganic binder, and designing the mixing rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com