Projector light source and forming method thereof

A projector and light source technology, which is applied in the field of projection light sources, can solve the problems of large volume, high cost, and complex optical path system structure, and achieve the effects of small size, low cost, and simplified optical path system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

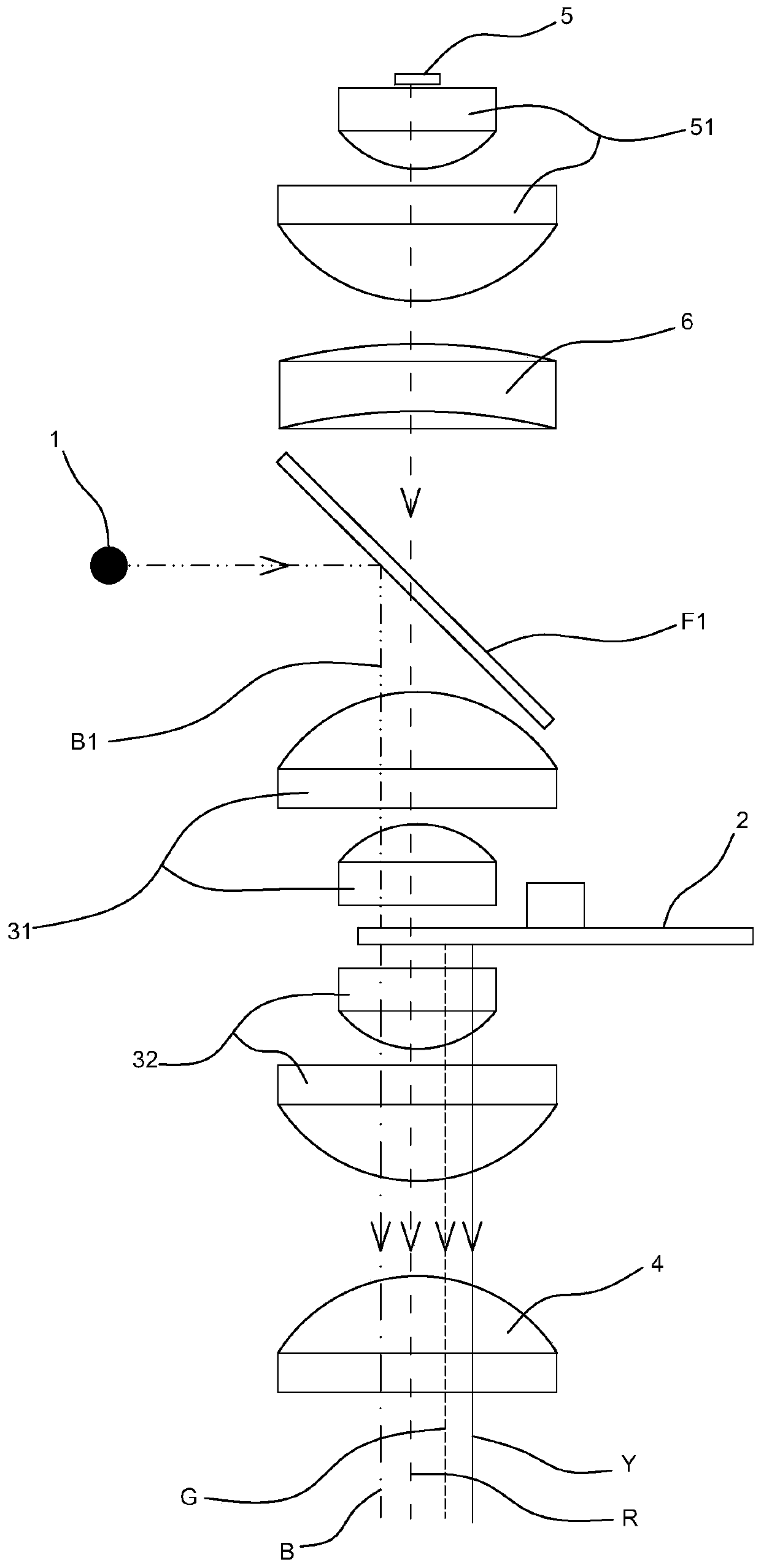

[0027] Embodiment one, with reference to figure 1 with image 3 As shown, a projector light source includes: an excitation light source 1 , a red LED light source 5 , a runner 2 , a light guide assembly, and a fourth collimating mirror 4 .

[0028] The excitation light source 1 is used to generate the blue laser beam B1; the red LED light source 5 is used to generate the first red projection beam R;

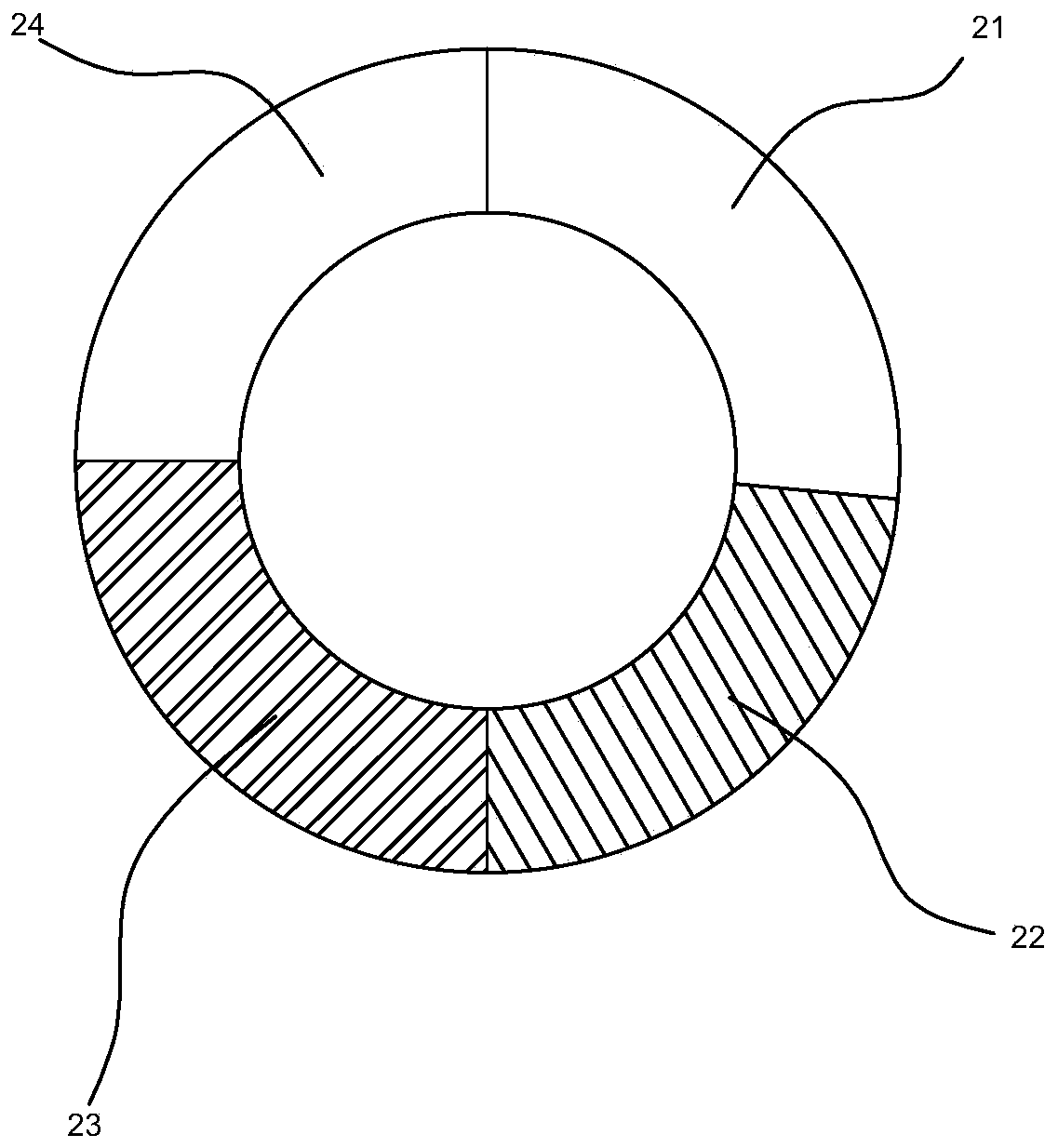

[0029] The rotary wheel 2 is rotatably arranged on the path of the laser beam B1 and the first projected beam R, and the rotary wheel 2 has a first penetration zone 21, a second penetration zone 24, a first wavelength conversion zone 23 and a second wavelength conversion zone. Zone 22, the first penetrating zone 21 is for the first projection beam R to penetrate and guide the projection direction, the second penetrating zone 24 is for the laser beam B1 to penetrate the second projection beam B that produces blue and guide the projection direction; the first The wavelength conve...

Embodiment 2

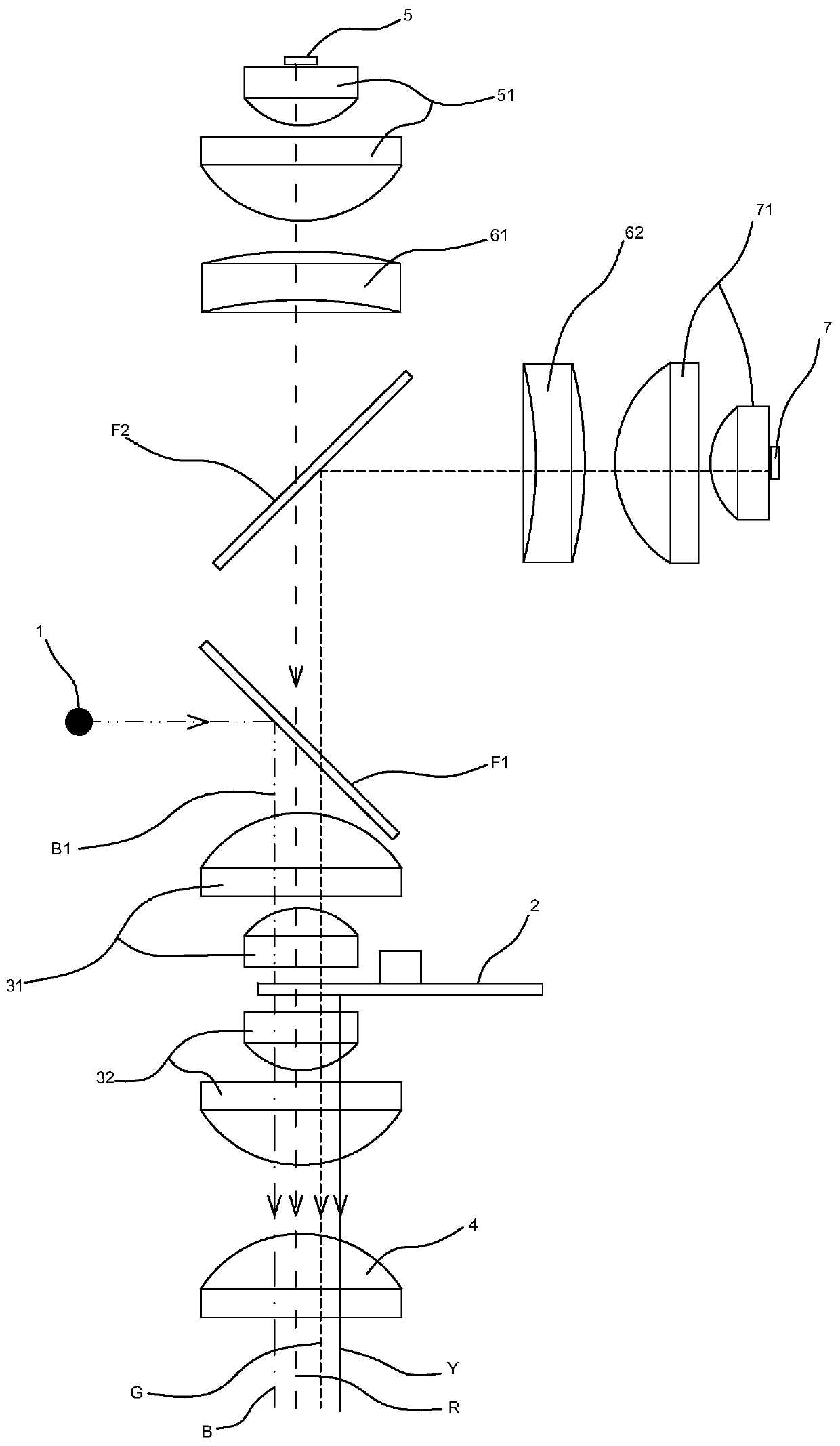

[0032] Embodiment two, refer to figure 2 with Figure 4 As shown, a projector light source includes: an excitation light source 1 , a red LED light source 5 , a green LED light source 7 , a second filter F2 , a runner 2 , a light guide assembly, and a fourth collimating mirror 4 .

[0033] The excitation light source 1 is used to generate the blue laser beam B1; the red LED light source 5 is used to generate the first red projection beam R; the light emitting side of the red LED light source 5 is sequentially provided with a third collimating mirror 51 and a relay mirror 61, The green LED light source 7 is used to generate the third green projection light beam G, and the light emitting side of the green LED light source 7 is provided with a third collimating mirror 71 and a relay mirror 62 in sequence.

[0034] The rotary wheel 2 is rotatably arranged on the path of the laser beam B1 and the first projection beam R, and the rotary wheel 2 has a first penetration zone 21, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com