Fault diagnosis method based on fault data deep mining and learning

A fault diagnosis and fault data technology, applied in the direction of electrical digital data processing, special data processing applications, digital data information retrieval, etc., can solve problems such as huge data storage, difficult analysis, increased diagnostic complexity, etc., to achieve improved robustness Performance and reliability, accurate and fast fault judgment, and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

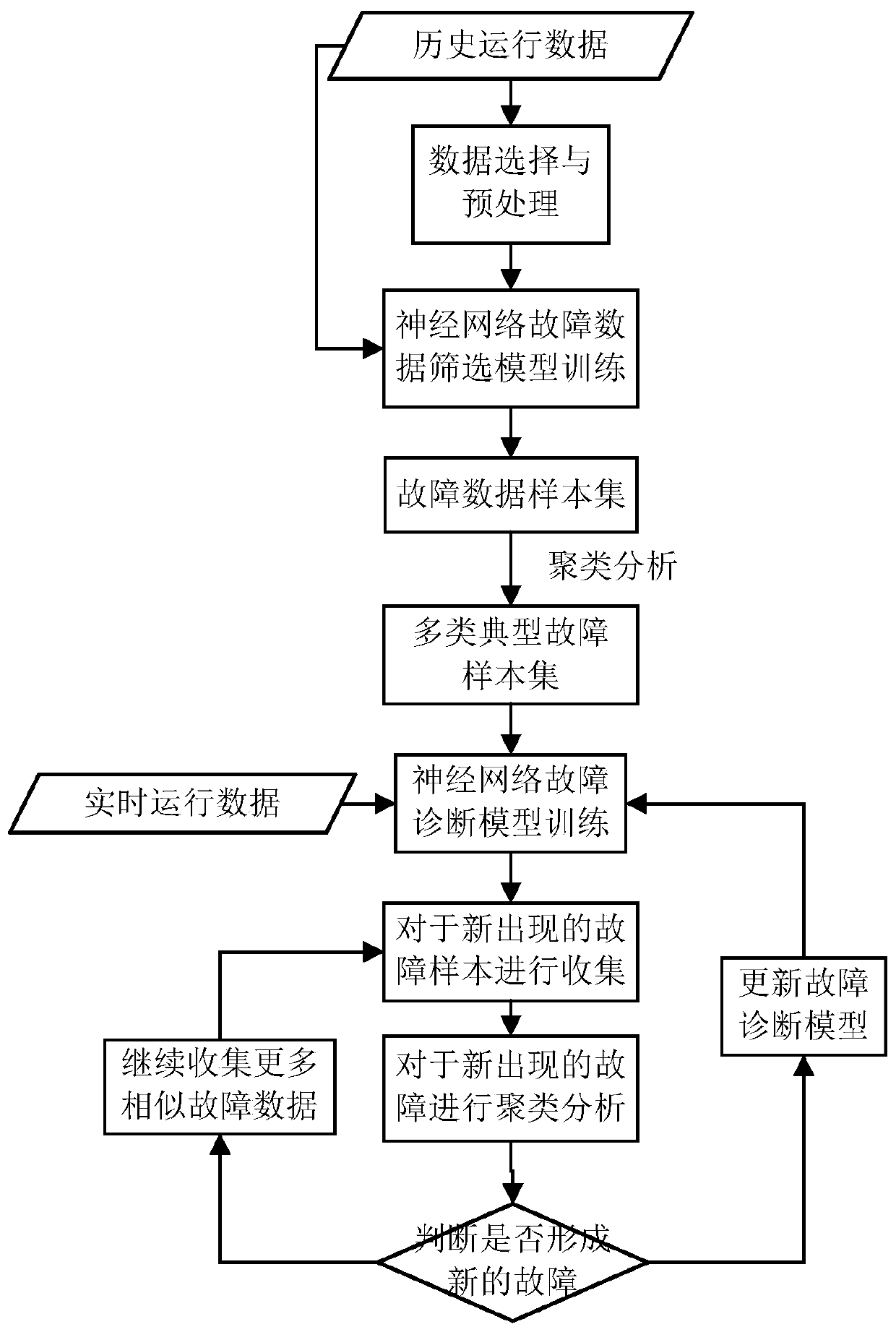

[0023] Such as figure 1 As shown, a fault diagnosis technology based on deep learning and historical data mining described in the present invention realizes the monitoring and diagnosis of real-time operating faults of the system and ensures safe and reliable operation of the system, including the following steps:

[0024] The first step is deep mining of historical fault data.

[0025] (1) Historical data collection. According to the input / output variables of the system, the effective historical data during the normal operation period of the system is collected from the massive historical database of the unit, and the historical data is preprocessed by discrete point detection, missing value completion and normalization, etc. The feature is scaled to a specific interval, and the original distribution is preserved, so that the neural network converges quickly. The normalized formula is:

[0026]

[0027] where x i is the original data, x max is the maximum value in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com