Battery silk-screen quality detection method combining block template matching with morphological processing

A quality detection method and morphological processing technology, applied in image data processing, image analysis, instruments, etc., can solve the problems of long detection time, complex algorithm, single application object characteristics, etc., to improve registration accuracy, convenient calibration, Good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

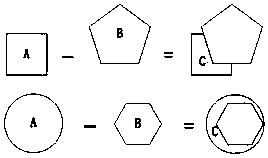

[0083] The invention provides a battery silk screen quality detection method based on block template matching combined with morphological processing. The battery silk screen is divided into a text part and an illustration part, and two types of methods are respectively designed according to the characteristics of the two parts. Finally, an organic combination is applied. The method can quickly and accurately complete the detection of silk screen quality.

[0084] The present invention relates to a battery screen printing quality detection method based on block template matching combined with morphological processing, comprising the following steps:

[0085] S1. Create template data and corresponding parameter configuration files

[0086] S101. Create a template for the illustration part

[0087] For the illustration part, the block template matching method is adopted, so each illustration is used as a unit to create a template. Since there are many types of battery silk scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com