Image sensor and formation method thereof

An image sensor and pixel technology, which is applied in the manufacture of electrical solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of reduced device performance, large alignment deviation, and increased resistance, and achieve the effect of improving device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

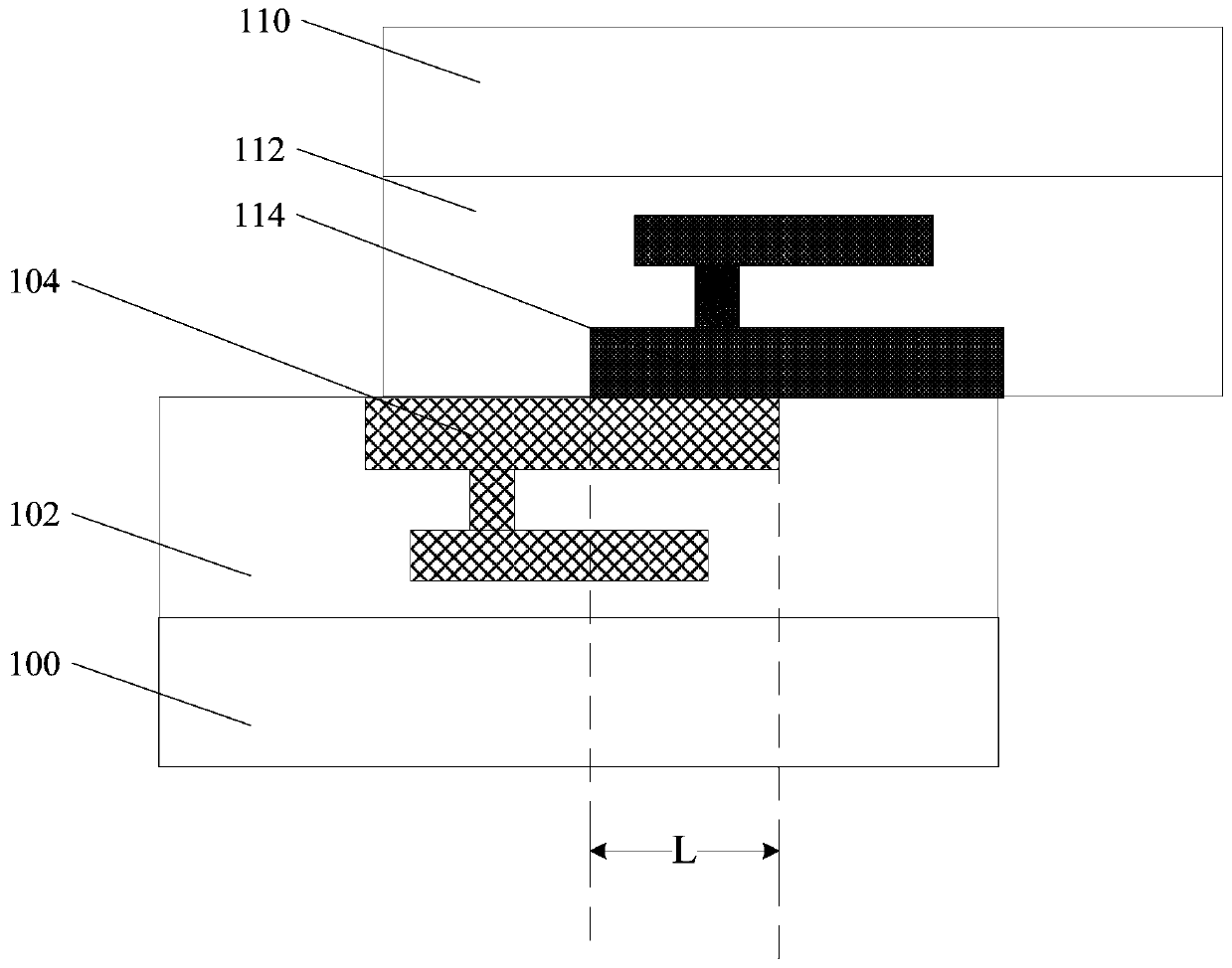

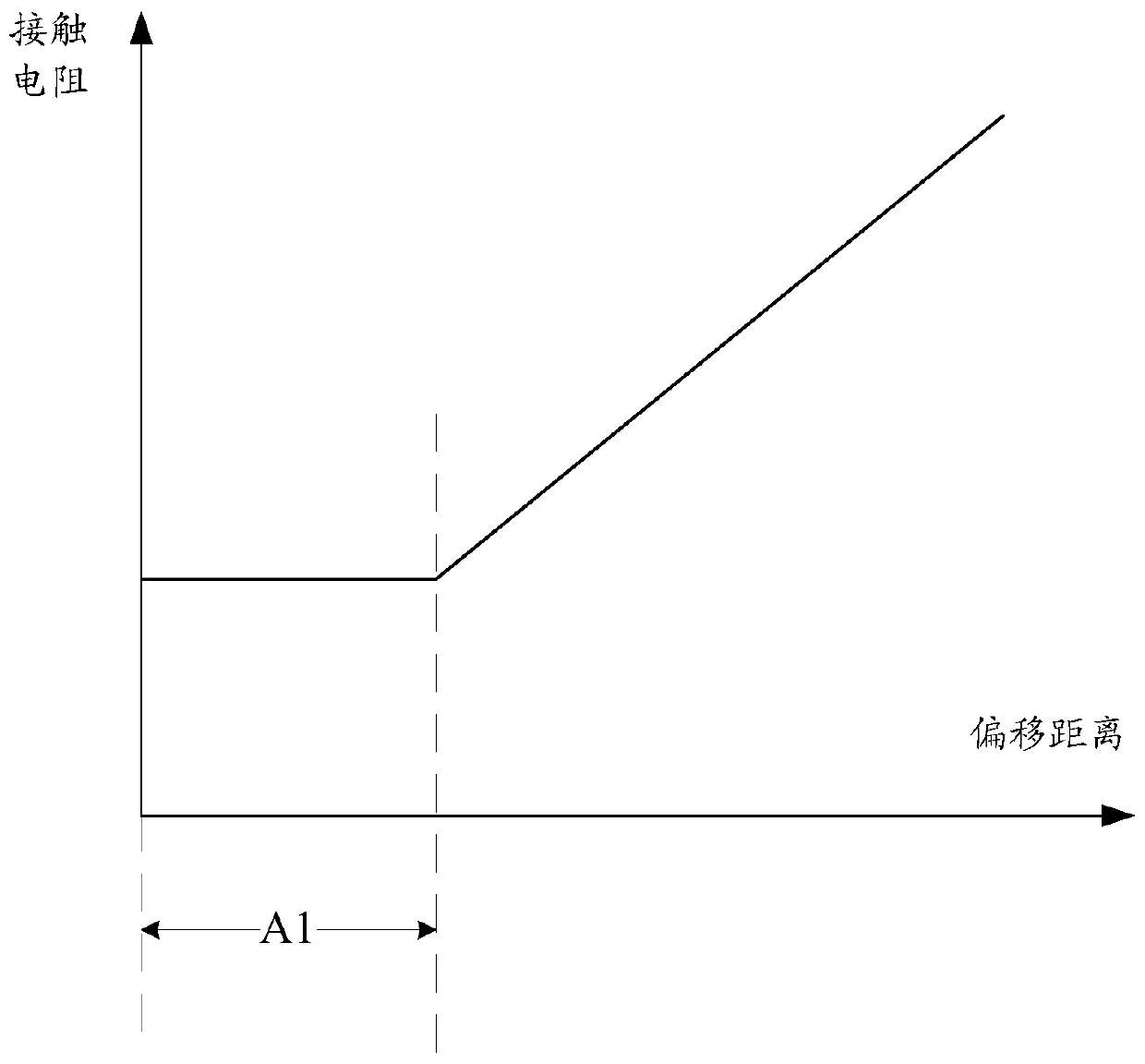

[0027] In the prior art, a logic wafer and a pixel wafer may be bonded by using metal bonding technology (such as Cu-Cu wafer bonding technology), so as to realize the interconnection function between the wafers. However, in the existing Cu-Cu wafer bonding technology, the problem of relatively large alignment deviation between corresponding pads is prone to occur, resulting in increased resistance and reduced device performance.

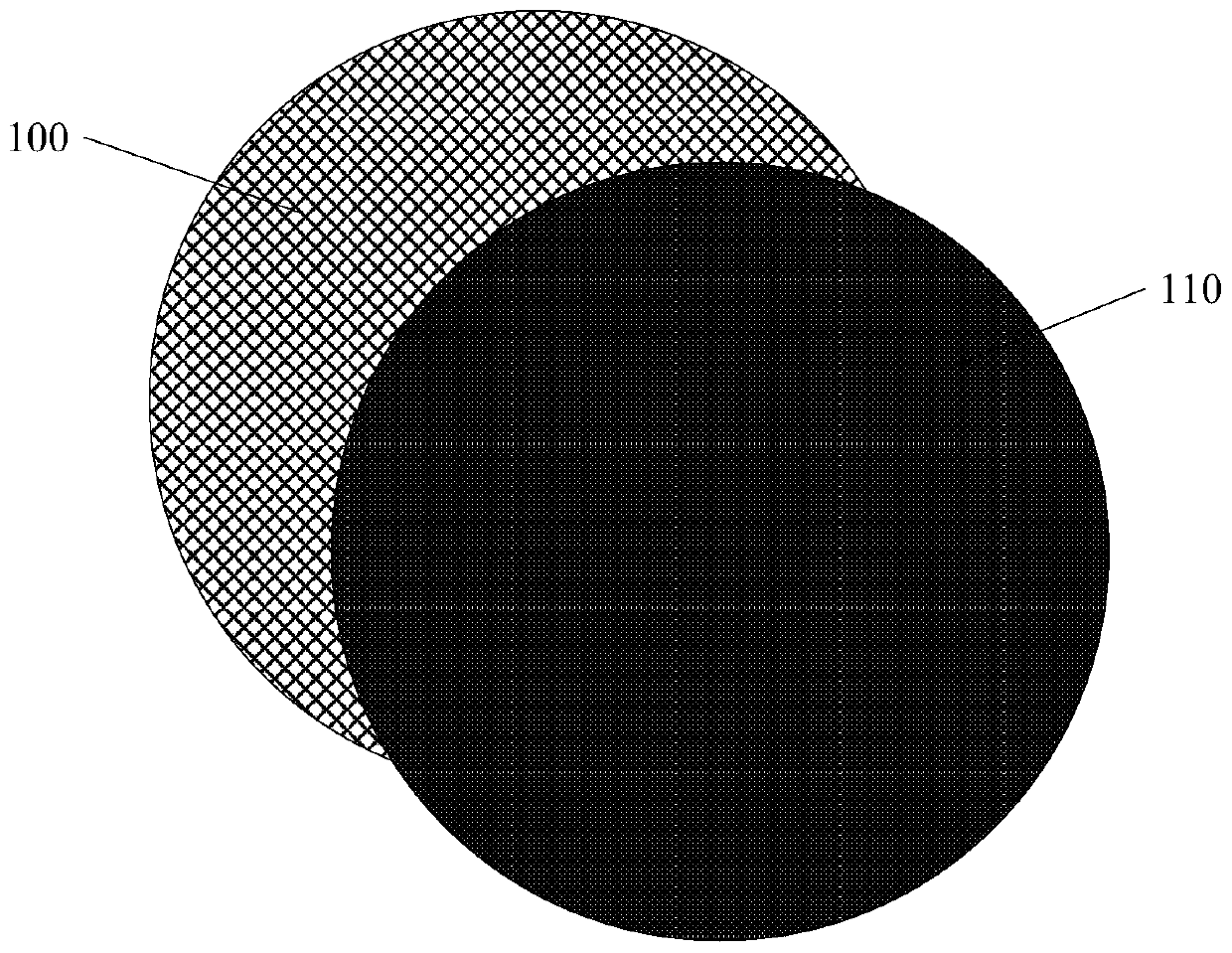

[0028] refer to figure 1 , figure 1 It is a schematic diagram of a working scene of wafer alignment in the prior art.

[0029] In a specific application, the first wafer 110 is usually grabbed by a robot arm, placed on the surface of the second wafer 100, and aligned, wherein the second wafer 100 can be fixed on the wafer substrate of the alignment chamber. seat.

[0030] The inventors of the present invention have found through research that in the prior art, if the uniformity of the pad pattern is not good, it is easy to cause bonding problems ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com