Method for using ionic liquid catalyst with surface activity for synthesizing ethoxyquin

A technology of ethoxyquinoline and ionic liquid, applied in organic chemistry, chemical recovery, etc., can solve the problems of high reaction temperature, long reaction time, high process cost, etc., achieve good thermal stability, reduce process cost, high acid The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

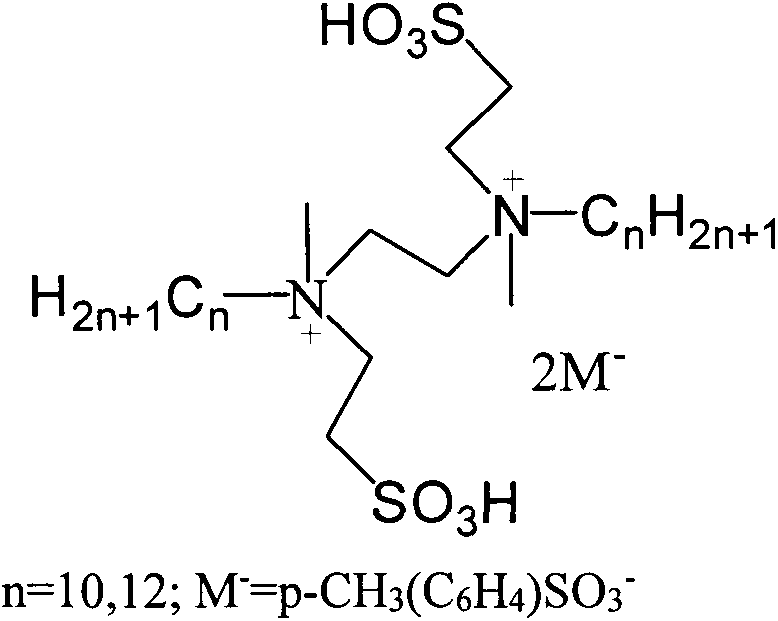

Method used

Image

Examples

Embodiment 1

[0020] Add 68.5g of p-aminophenethyl ether and 14g of catalyst into the reactor at one time, mix thoroughly, heat up, and add 64g of acetone dropwise under normal pressure at a reaction temperature of 70°C. The reaction time is 6h, and the reaction The temperature of the liquid is cooled to room temperature, and the unreacted acetone is condensed and then enters the acetone recovery device to recover acetone; a small amount of water is added to the reaction liquid, the liquid is separated, and the lower layer is separated for catalyst recovery and recycling; the upper layer ethoxyquinoline material separated by water is washed After the liquid is distilled, the finished product is obtained with a yield of 65%.

Embodiment 2

[0022] Add 68.5g of p-aminophenethyl ether and 14g of ionic liquid into the reactor at one time, mix thoroughly, heat up, and add 64g of acetone dropwise under normal pressure at a reaction temperature of 100°C. The reaction time is 5h. The temperature of the reaction liquid is cooled to room temperature, and the unreacted acetone is condensed and put into the acetone recovery device to recover acetone; a small amount of water is added to the reaction liquid, the liquid is separated, and the lower layer is separated for catalyst recovery and recycling; the separated upper layer of ethoxyquinoline is washed with water The finished product is obtained after the feed liquid is distilled, and the yield is 88%.

[0023] Example 3

[0024] Add 68.5g of p-aminophenethyl ether and 20g of ionic liquid into the reactor at one time, mix thoroughly, heat up, and add 64g of acetone dropwise under normal pressure at a reaction temperature of 110°C. The reaction time is 5h. The temperature ...

Embodiment 4

[0026] Add 68.5g of p-aminophenethyl ether and 20g of ionic liquid into the reactor at one time, mix thoroughly, heat up, and add 70g of acetone dropwise under normal pressure at a reaction temperature of 110°C. The reaction time is 8h. The temperature of the reaction solution is lowered to below 60°C, and the unreacted acetone is condensed and then enters the acetone recovery device to recover acetone; the reaction solution is washed with water, and the lower catalyst aqueous solution is separated, and the catalyst is recovered and recycled; the upper layer ethoxyquinoline separated by water is washed The finished product is obtained after the feed liquid is distilled, and the yield is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com