Device and method of iron powder cold-pressing reduction

A technology of iron powder and cold pressing, which is applied in the field of iron powder cold pressing reduction equipment, can solve the problems of wasting time, manpower and financial resources, increasing equipment load, affecting production capacity, etc. circle chance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

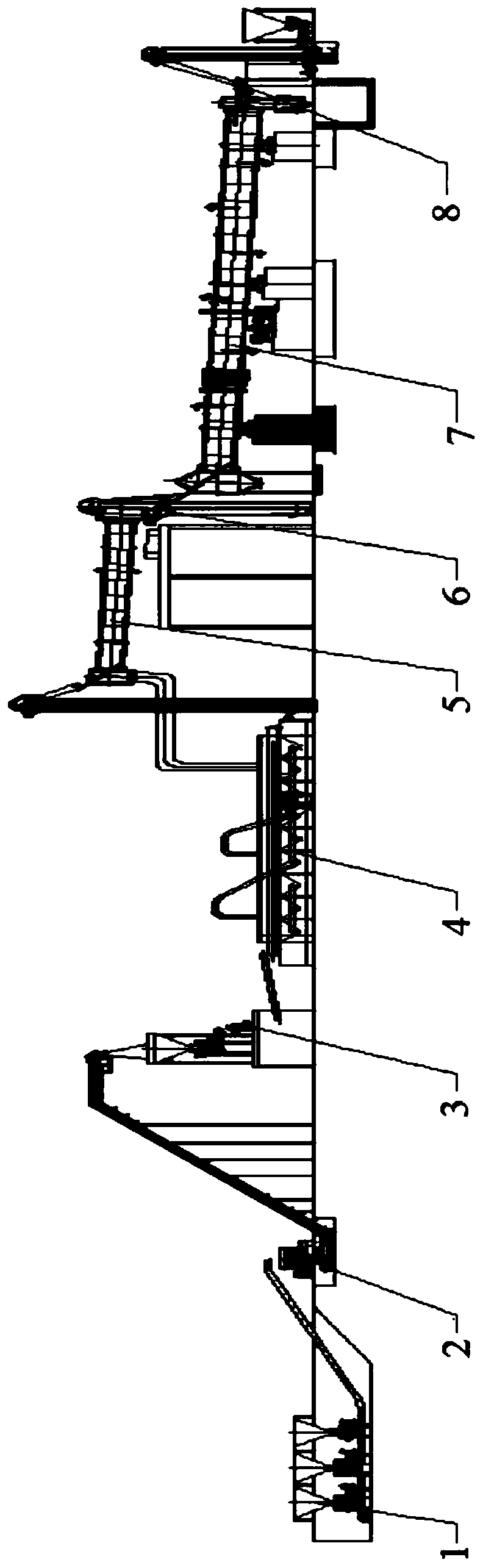

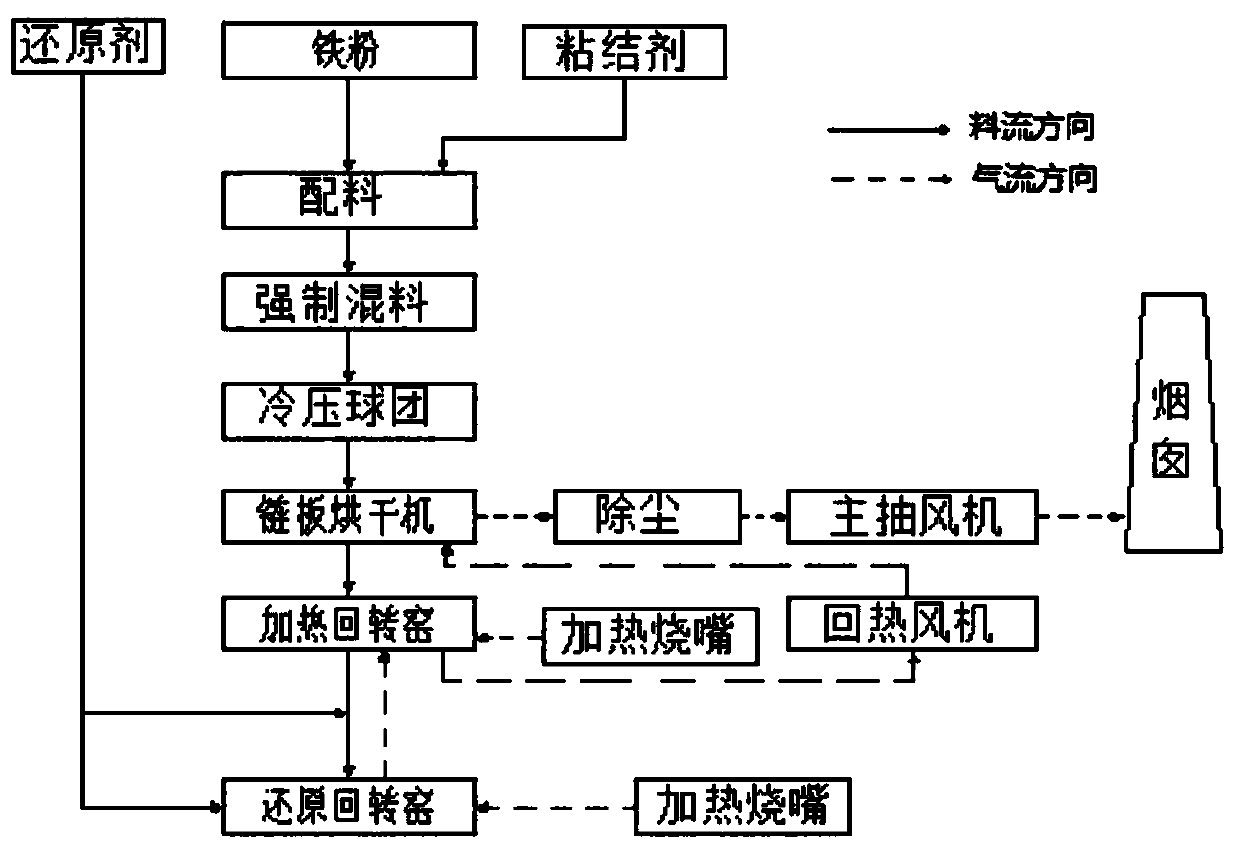

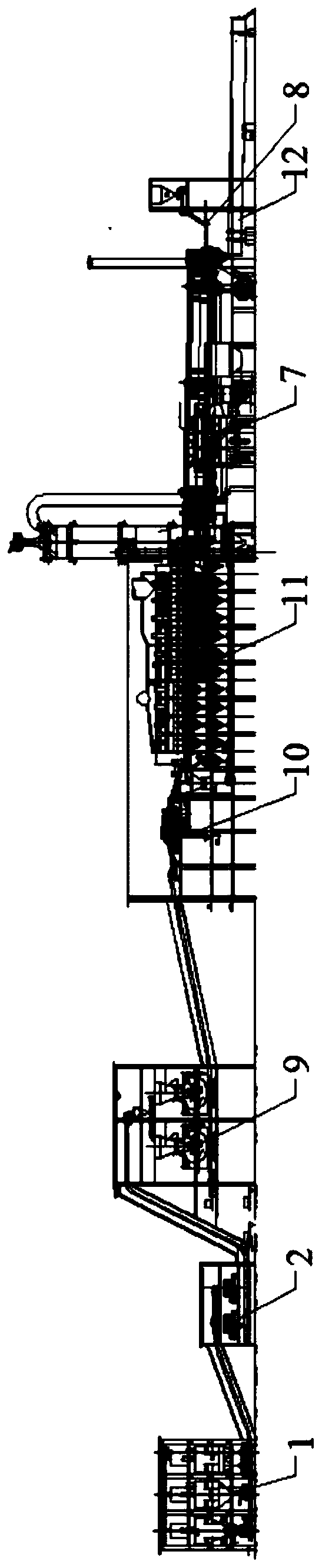

[0032] Such as figure 1 As shown, this embodiment provides an iron powder cold pressing reduction device, including a batching system 1, a forced mixing system 2, a double-roller ball press 3, a chain plate dryer 4, a heating rotary kiln 5, a swing screen 6, The reduction rotary kiln 7 and the reducing agent injection system 8. The batching system 1 is used to batch the iron powder and the binder in proportion and transport the finished iron powder and the binder to the forced mixing system 2. The forced mixing system 2 It is used to mix the finished iron powder and the binder uniformly and transport the evenly mixed iron powder and binder to the double-roller ball press 3, the double-roller ball press 3 is used to mix the evenly mixed iron The powder and binder are pressed into cold-pressed pellets and transported to the chain plate dryer 4, which is used to dry and preheat the cold-pressed pellets and dry preheat The latter cold-pressed pellets are transported to the heating...

Embodiment 2

[0037] This embodiment provides a method for cold-pressing reduction of iron powder. The cold-pressing reduction device for iron powder in the first embodiment is adopted and includes the following steps:

[0038] (1) Mix the iron powder and the binder through the batching system 1. After the batching is completed, the iron powder and the binder are mixed evenly through the forced mixing system 2;

[0039] (2) Press the evenly mixed iron powder and binder into cold-pressed pellets in the double-roller ball press 3;

[0040] (3) Dry and preheat the cold-pressed pellets on the chain plate dryer 4;

[0041] (4) Send the preheated cold-pressed pellets into the heating rotary kiln 5 for heating and sintering, so that the temperature of the cold-pressed pellets reaches 1050~1150℃, and the compressive strength of the cold-pressed pellets is greater than 160Kg / ball;

[0042] (5) The cold-pressed pellets after heating and sintering are screened by a swing screen 6, and the powder in them is scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com