VOCs treatment system by centrifugal oxidation method combined with micro-nano bubbles

A micro-nano bubble and treatment system technology, applied in the field of centrifugal oxidation method and micro-nano bubble VOCs treatment system, can solve the problems of low treatment efficiency, long treatment time, low wind speed, etc., to reduce operating costs and prolong service life , easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in this embodiment will be clearly and completely described below in conjunction with the accompanying drawings in this embodiment. However, this should not be construed as limiting the present invention to specific embodiments, but only for explanation and understanding:

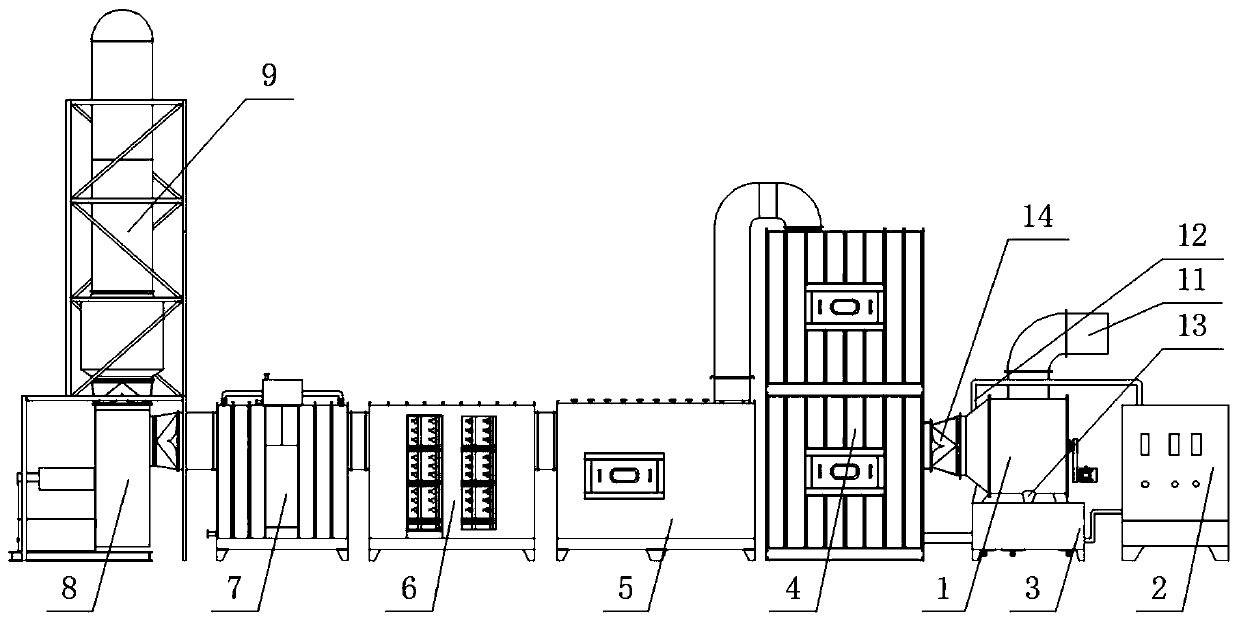

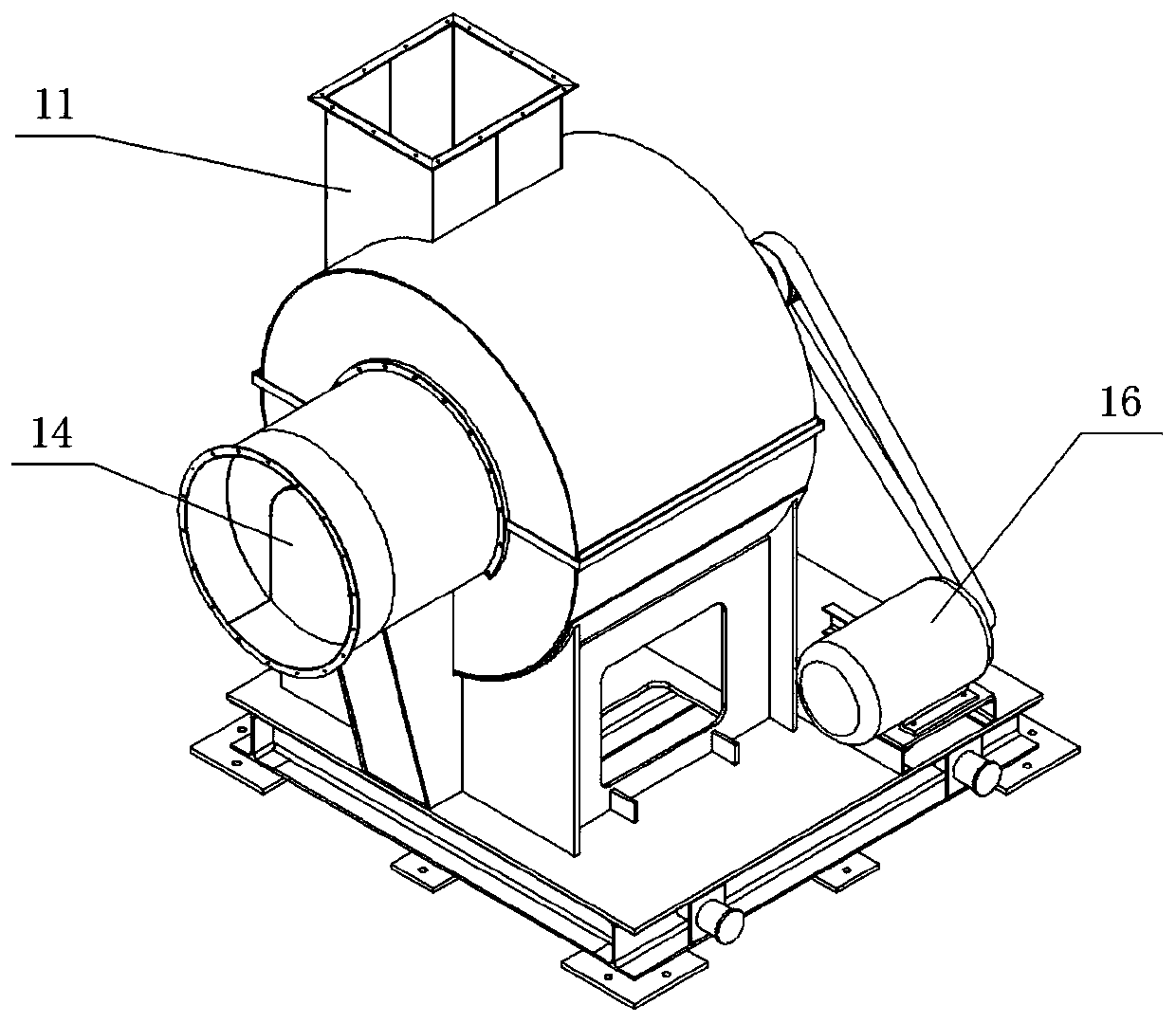

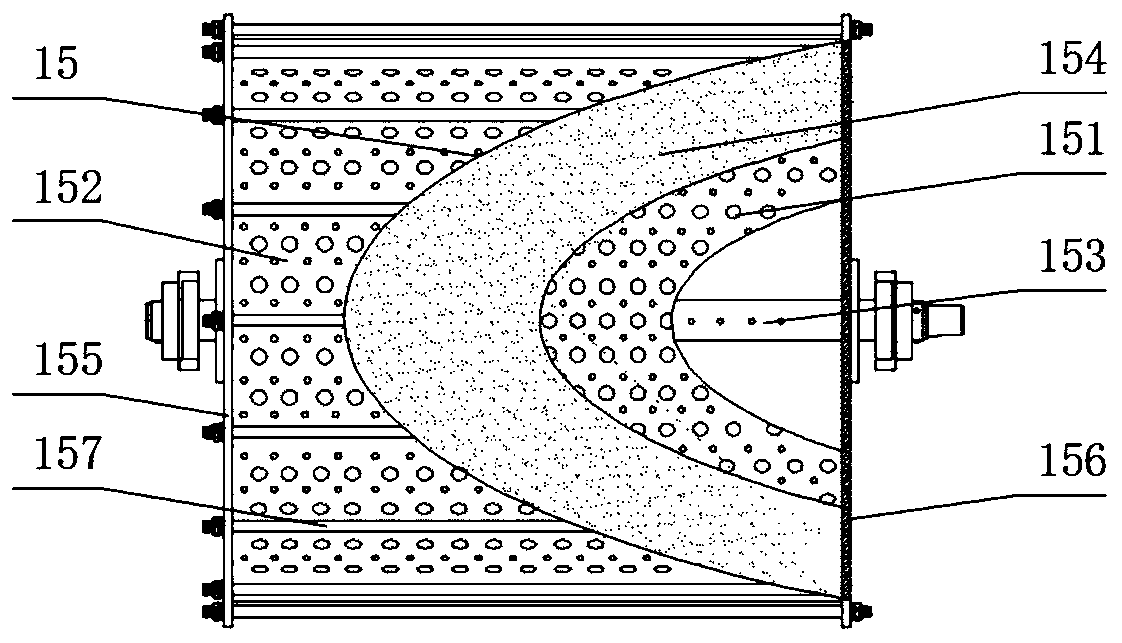

[0034] Such as figure 1As shown, a centrifugal oxidation method combined with micro-nano bubble VOCs treatment system includes a centrifugal separation and desorption device 1, and the centrifugal separation and desorption device 1 includes a shell on which a first air inlet pipe 11 and a first water inlet pipe are installed. 12. The first drain pipe 13 and the first exhaust pipe 14, the first intake pipe 11 is connected to the VOCs gas source, the first water inlet pipe 12 is connected to the micro-nano bubble ozone generator 2, and the first drain pipe 13 is connected to the purified water tank 3 , the first exhaust pipe 14 is connected with a defoaming device 4, the defoami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com