Production process for high-strength fiber-cement hollow lattice plates

A high-strength fiber and production process technology, applied in the field of building materials, can solve the problems of high environmental pollution, low level of production process automation, long production cycle, etc., achieve long service life, benefit environmental protection, and save mold production costs and time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

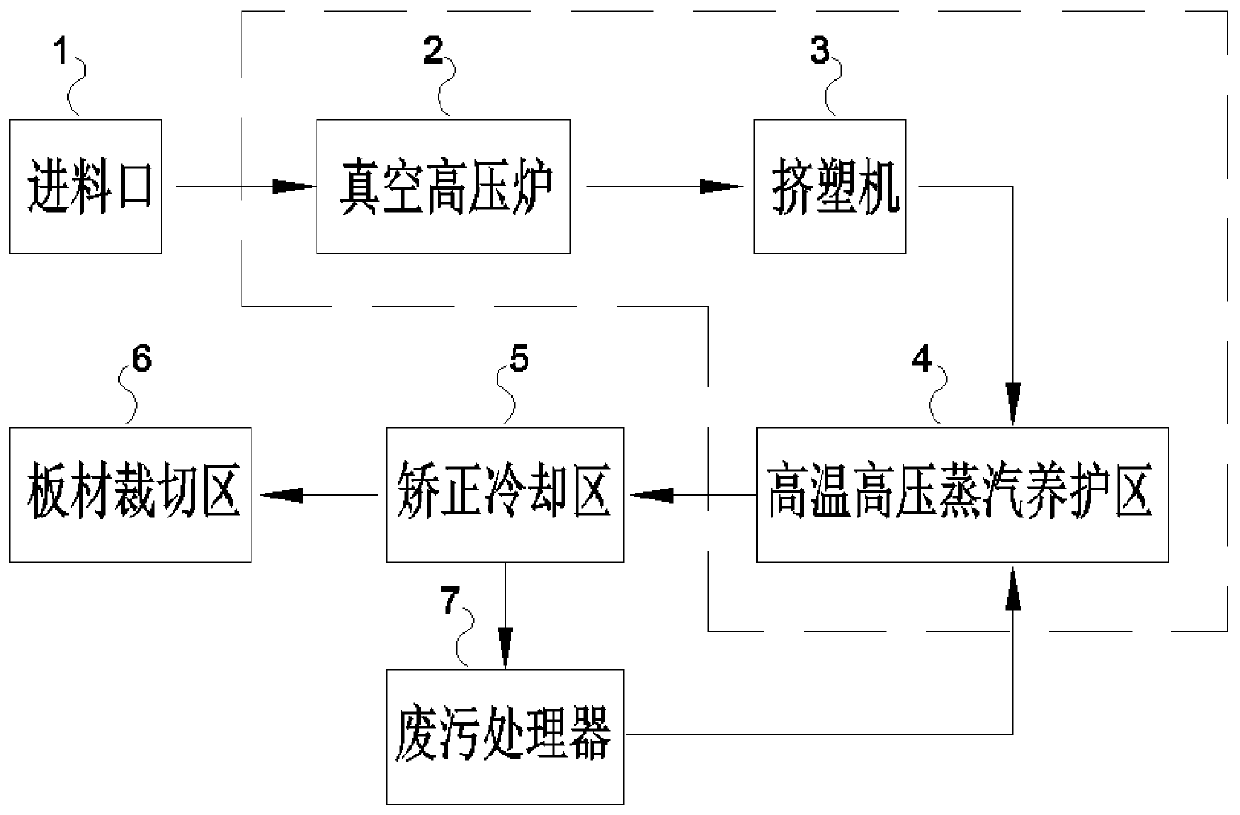

[0014] Such as figure 1 As shown, a high-strength fiber cement hollow lattice panel production process includes the following steps:

[0015] Step 1: The raw materials are mixed and stirred at the feed inlet 1 and then melted in the vacuum high-pressure furnace 2; the raw materials are cement mortar, chopped carbon fiber, and siliceous materials (natural stone powder, fly ash, tailings, etc.).

[0016] Step 2, the material melted in the vacuum high-pressure furnace 2 is extruded through the corresponding mold of the extruder 3 to extrude the board, and transported by the conveyor belt to the high-temperature and high-pressure steam curing 4 for curing of the board.

[0017] Step 3: After curing, the plates are sent to rectification and cooling 5 to cool the plates and then cut and form the plates in the plate cutting 6, and the waste water and waste gas are recycled and utilized through the waste processor 7.

[0018] Conveyor belts are used to transport materials between eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com