White light emitting material as well as preparation method and application thereof

A luminescent material and white light technology, which is applied in the field of white light luminescent material and its preparation, can solve problems such as complex preparation methods, and achieve the effect of saving raw material costs, saving raw material and manufacturing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

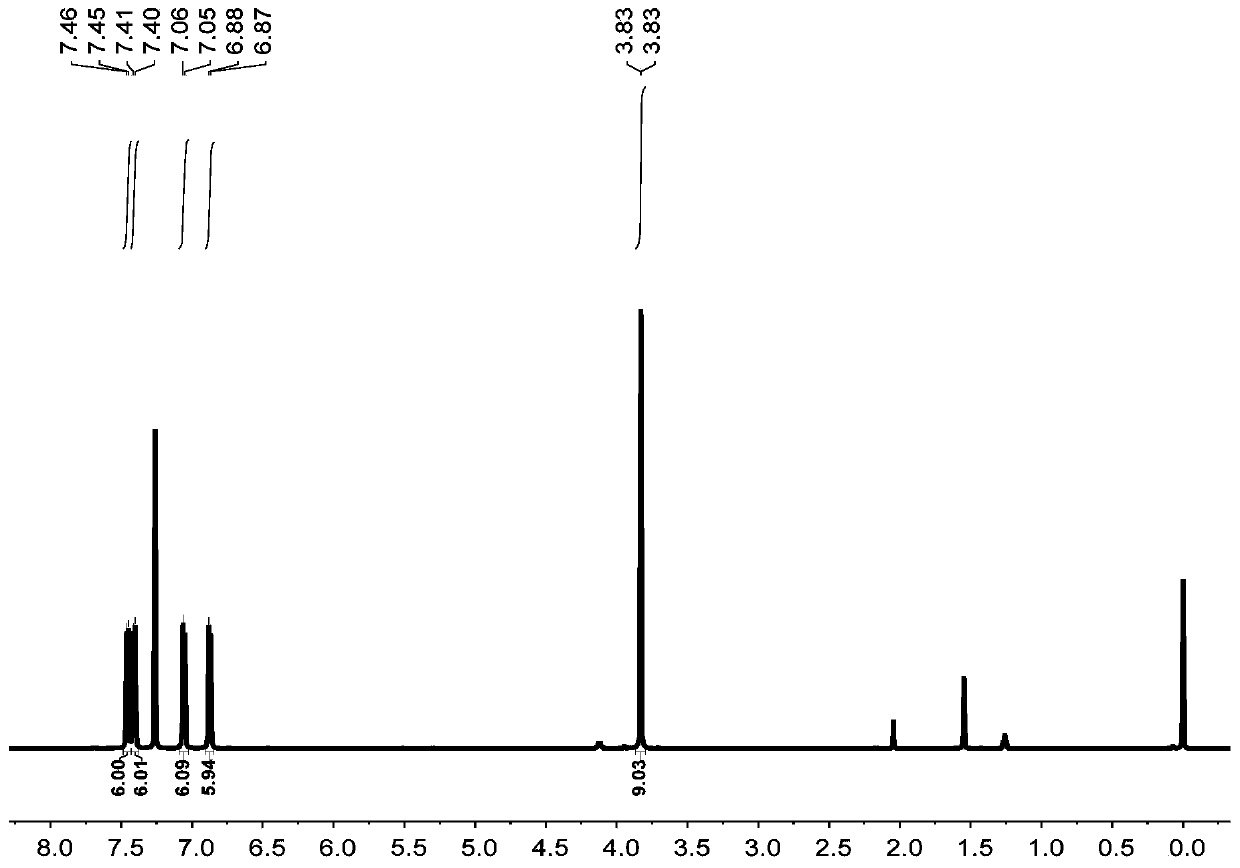

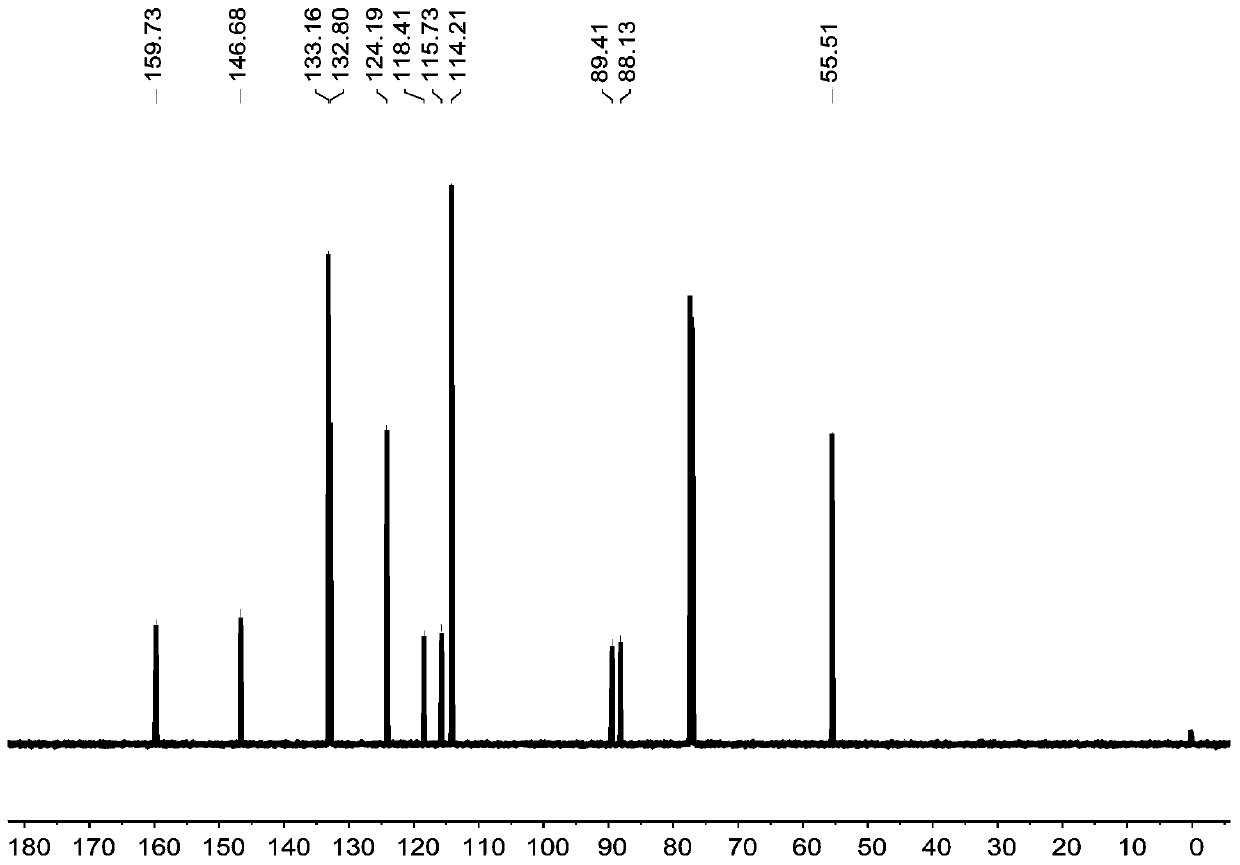

[0070] In this embodiment, a white light emitting material is synthesized, and the chemical structural formula of the white light emitting material is as follows:

[0071]

[0072] Its preparation method comprises the following steps:

[0073] (1) Put 5.0mmol tris(4-iodophenyl)amine, 21.0mmol 4-methoxyphenylacetylene, 30.0mL tetrahydrofuran, and 7.0mL triethylamine into a 100mL double-necked flask equipped with a stirring bar, and connect return pipe;

[0074] (2) The above reaction mixture is evacuated with a vacuum pump so that the pressure reaches 1×10 -2 After Pa, feed nitrogen, repeat pumping and pass nitrogen three times, keep reaction system nitrogen atmosphere;

[0075] (3) 0.125mmol tetrakis (triphenylphosphine) palladium and 0.8mmol cuprous iodide are added in the above reaction solution under nitrogen environment;

[0076] (4) The above reaction mixture was heated to 70° C. under nitrogen protection, and kept under reflux for 10 hours. Then the solvent was ev...

Embodiment 2

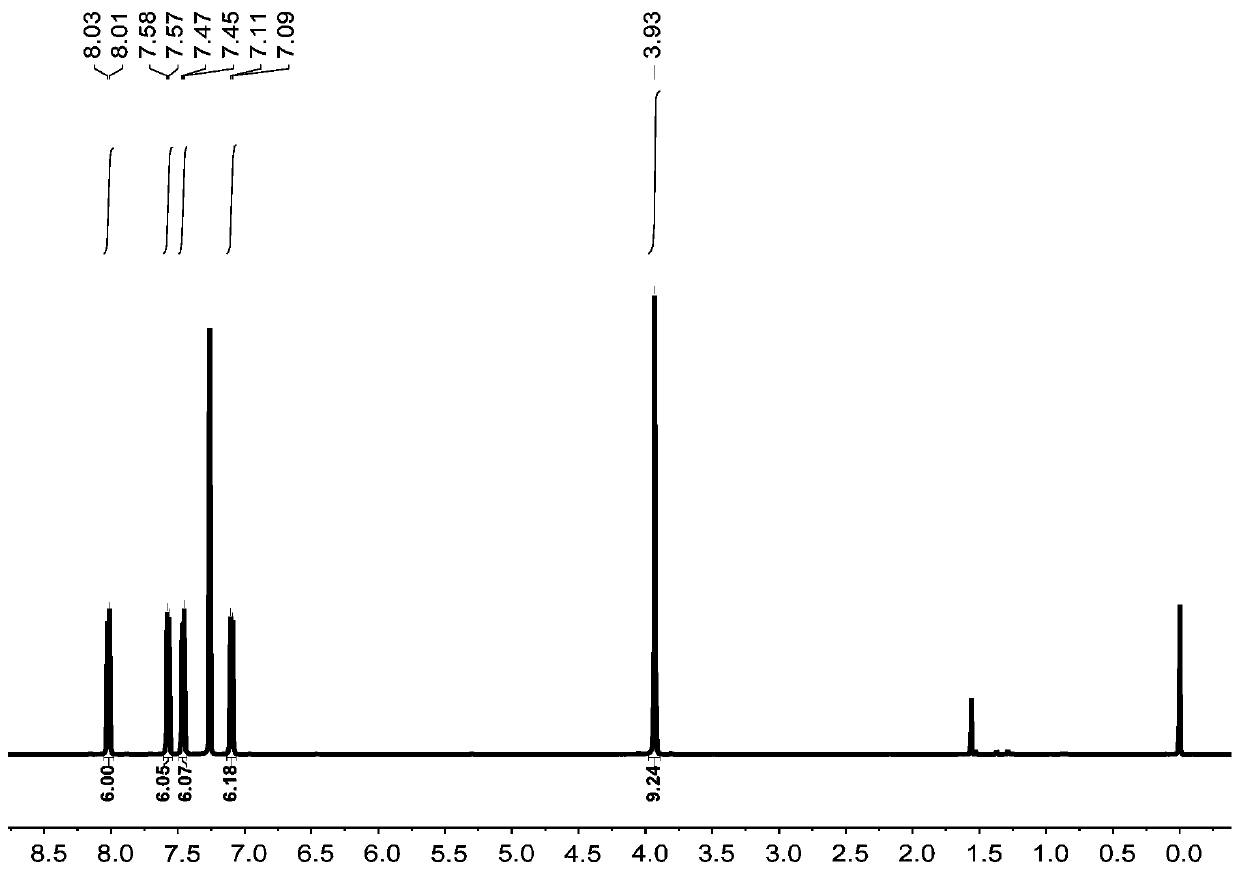

[0081] In this embodiment, a white light emitting material is synthesized, and the chemical structural formula of the white light emitting material is as follows:

[0082]

[0083] Its preparation method comprises the following steps:

[0084] (1) Put 5.0mmol tris(4-iodophenyl)amine, 21.0mmol methyl 4-ethynylbenzoate, 30.0mL tetrahydrofuran, and 7.0mL triethylamine into a 100mL double-necked flask equipped with a stirring bar, and Connect the return pipe;

[0085] (2) The above reaction mixture is evacuated with a vacuum pump so that the pressure reaches 1×10 -2 After Pa, feed nitrogen, repeat pumping and pass nitrogen three times, keep reaction system nitrogen atmosphere;

[0086] (3) 0.125mmol tetrakis (triphenylphosphine) palladium and 0.8mmol cuprous iodide are added in the above reaction solution under nitrogen environment;

[0087] (4) The above reaction mixture was heated to 70° C. under nitrogen protection, and kept under reflux for 10 hours. Then the solvent wa...

Embodiment 3

[0092] This embodiment provides a white light organic light emitting diode, the preparation method of which includes the following steps:

[0093] (1) Place the glass substrate with 200nm anode material ITO in pure water, acetone and isopropanol in sequence, and ultrasonically clean them for 15 minutes respectively;

[0094] (2) spin-coat polyethylenedioxythiophene-poly(styrene sulfonate) with a thickness of 20 nm on the surface of the ITO material after cleaning in step (1);

[0095] (3) Place the product obtained in step (2) on a heating platform and heat it to 150°C, and then keep it for 15 minutes;

[0096] (4) the material that embodiment 1 is made in 10 -5 Under the pressure of Pa and the speed of 0.5 angstroms / second, thermal vacuum evaporation is deposited on the polyethylenedioxythiophene-poly(styrene sulfonate) layer of the product of step (3), forming a white light emitting layer of 40nm;

[0097] (5) Heat the product obtained in step (4) to raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com