A kind of production method of high-strength cement

A technology of high-strength cement and production method, applied in the field of cement, can solve the problems of limited cement adhesion and strength, insufficient mixing of raw materials, and easy to agglomerate, so as to reduce the phenomenon of agglomeration, fully stir, and increase stirring. Evenness of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

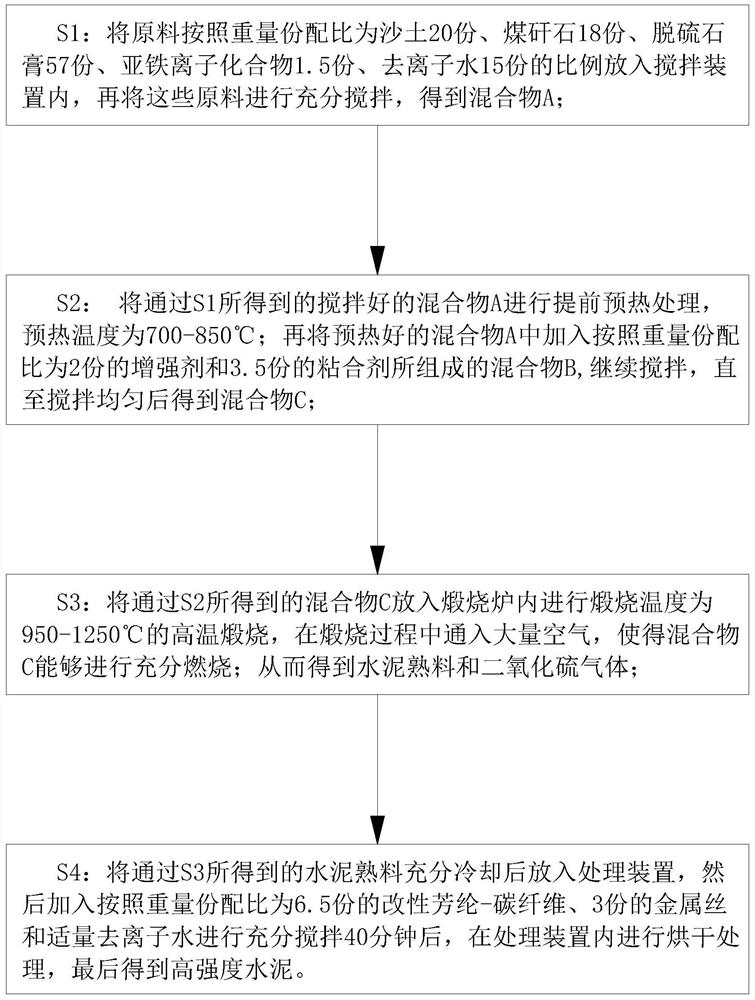

Method used

Image

Examples

Embodiment approach

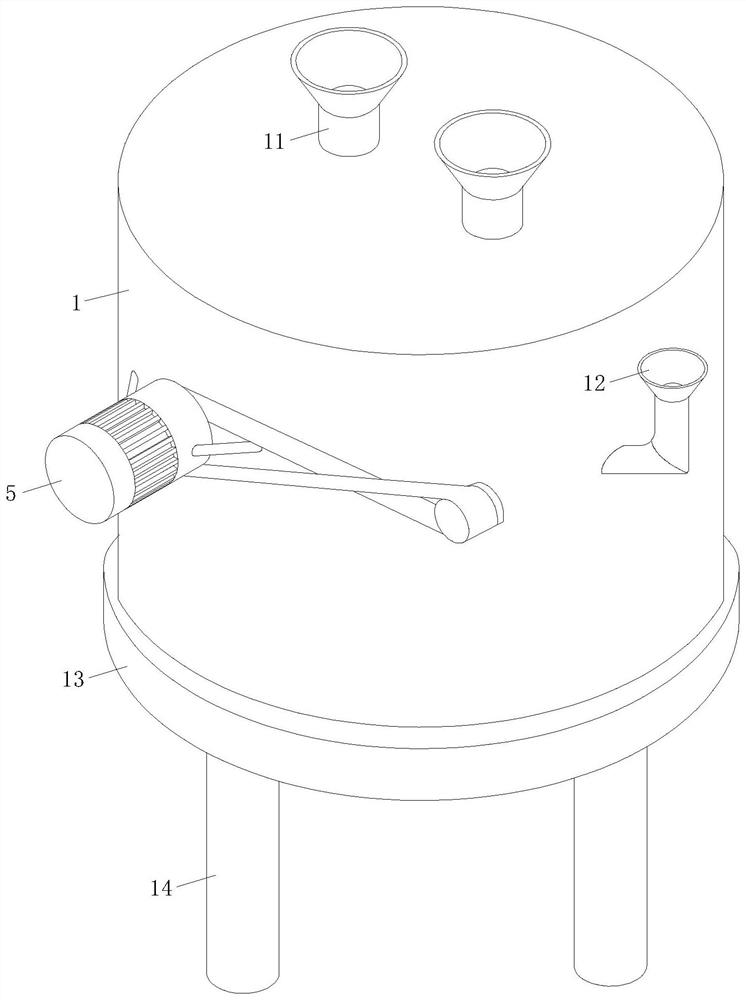

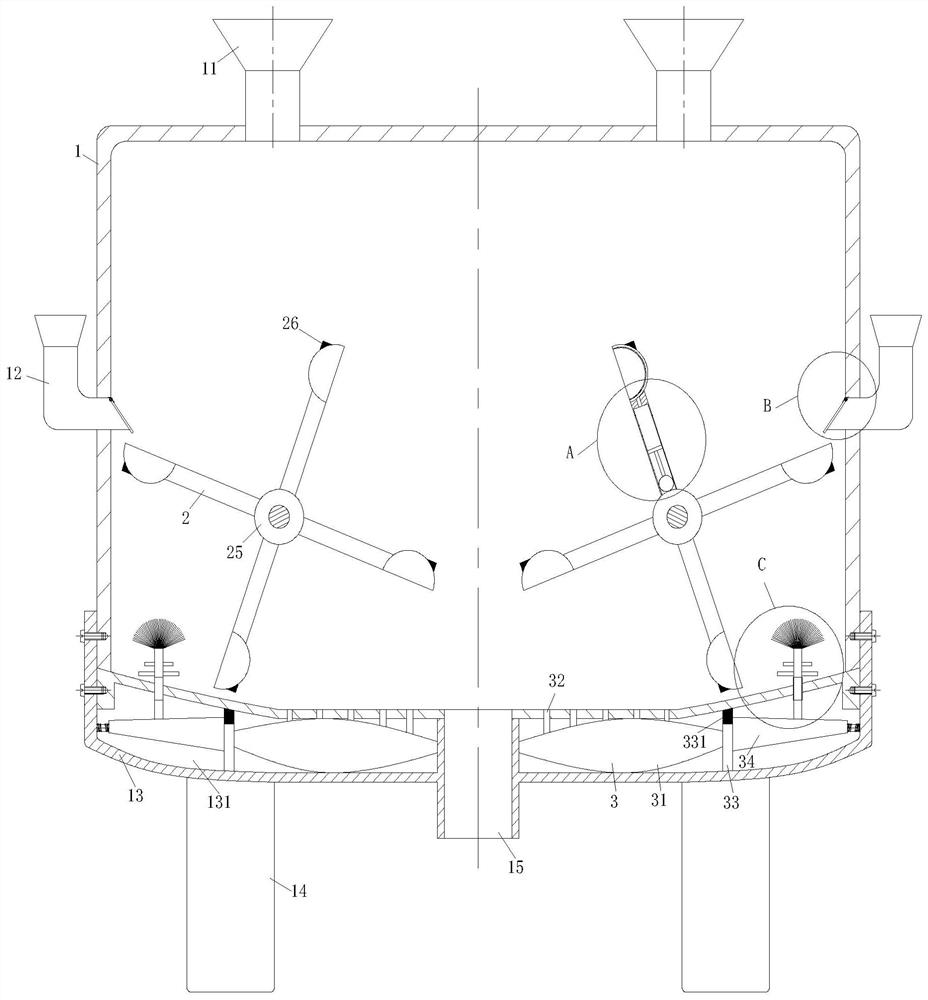

[0035] As an embodiment of the present invention, a baffle 122 is provided at the discharge port of the No. 2 feeding pipe 12; the baffle 122 is connected with the No. 2 feeding pipe 12 through a torsion spring 121, During the rotation process of the baffle plate 122, there is interference between the end of the baffle plate 122 and the spoon-shaped end of the stirring fan blade 2; through the cooperation of the motor 5, the stirring fan blade 2 and the baffle plate 122, uniform discharge during the stirring process is realized; use , the motor 5 rotates after being energized, and drives the stirring blade 2 to rotate. During the rotation of the stirring blade 2, the end of the stirring blade 2 will lift the baffle plate 122, so that part of the raw material is put into the stirring through the No. 2 feeding pipe 12. In the device, the effect of uniform feeding is realized, which prevents all the raw materials from being poured into the mixing device at one time during the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com