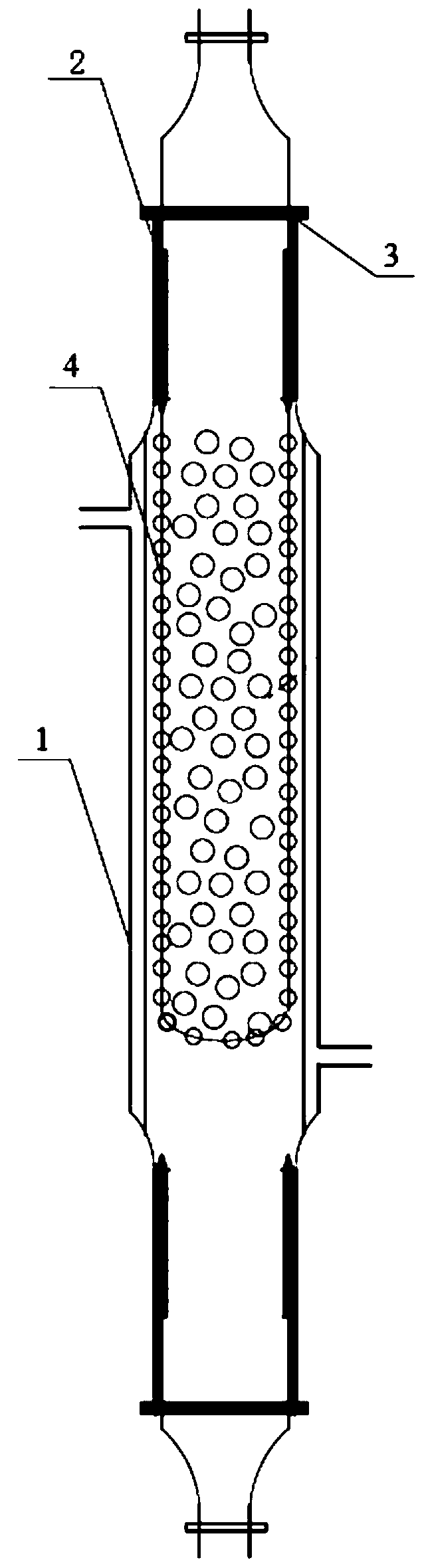

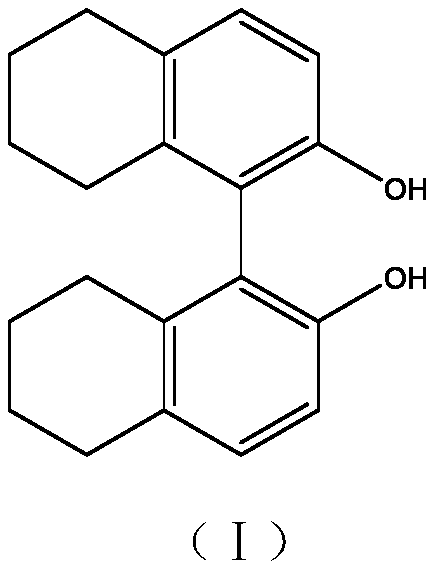

Purification method for octahydro-1,1'-bi-2-naphtol (H8-BINOL)

A purification method, the technology of binaphthol, applied in the field of separation and purification of fine chemicals, can solve the problems of low solubility, large amount of recrystallization solvent, cumbersome operation process, etc., to reduce the amount of solvent used, and facilitate disassembly and cleaning , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

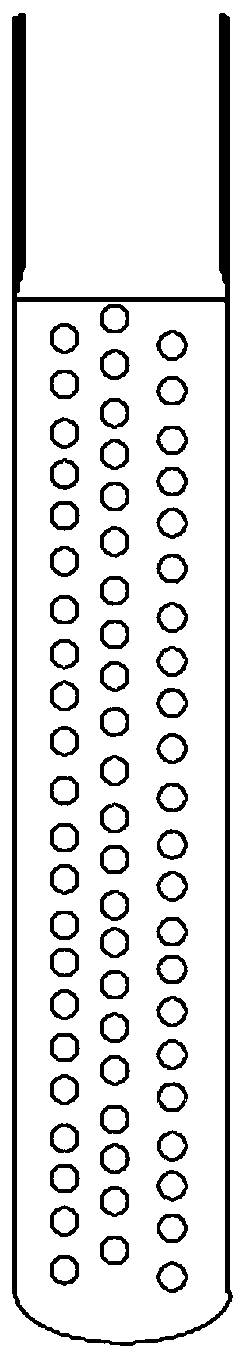

Method used

Image

Examples

Embodiment 1

[0027] Add 50g of silica gel powder to the ground casing in the purification device, raise the temperature of the heat transfer medium in the condensation tube in the purification device to 40°C, and prepare the 5,5',6,6',7,7 1500mL of ',8,8'-octahydro-1,1'-bi-2-naphthol reaction solution was passed into the purification device, purified by a silica gel powder bed to obtain a purified solution, and the solvent of the purified solution was evaporated completely, 5,5',6,6',7,7',8,8'-octahydro-1,1'-bi-2-naphthol with a content of 99.3% was obtained.

Embodiment 2

[0029]Add 50g of silica gel powder to the ground casing in the purification device, raise the temperature of the heat transfer medium in the condensation tube in the purification device to 60°C, and use binaphthol as raw material to prepare 5,5',6,6',7,7 1500mL of ',8,8'-octahydro-1,1'-bi-2-naphthol reaction solution was passed into the purification device, purified by a silica gel powder bed to obtain a purified solution, and the solvent of the purified solution was evaporated completely, 5,5',6,6',7,7',8,8'-octahydro-1,1'-bi-2-naphthol with a content of 99.7% was obtained.

Embodiment 3

[0031] Add 50g of silica gel powder to the ground casing in the purification device, raise the temperature of the heat conduction medium in the condensation tube in the purification device to 80°C, and use binaphthol as raw material to prepare 5,5',6,6',7,7 1500mL of ',8,8'-octahydro-1,1'-bi-2-naphthol reaction solution was passed into the purification device, purified by a silica gel powder bed to obtain a purified solution, and the solvent of the purified solution was evaporated completely, 5,5',6,6',7,7',8,8'-octahydro-1,1'-bi-2-naphthol with a content of 99.2% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com