Master alloy for improving the hardness of pure gold and pure silver, its preparation method and application

A technology of master alloy and pure silver, which is applied in the field of master alloys to improve the hardness of pure gold, preparation and pure silver, can solve problems such as poor casting performance, and achieve good oxidation resistance, enhanced sweat corrosion resistance, and small addition amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a preparation method of the master alloy. The method is to prepare the raw materials of each element according to the required dosage ratio, all of which are processed into -80~-325 mesh powder (the powder is prepared by mechanical method and electrolysis method), and then uniformly mixed, The obtained alloy powder is the master alloy powder. The powder is prepared by mechanical processing or electrolysis, which can solve the problems of composition segregation and difficult processing in the smelting method, and is easy to adjust the composition and industrialized production.

[0063] The present invention also provides another embodiment of the preparation method of the master alloy, the method is an alloying method, specifically comprising the following steps:

[0064] Prepare various raw material components according to the required weight ratio, and then add them into a vacuum melting furnace for smelting. The furnace temperature...

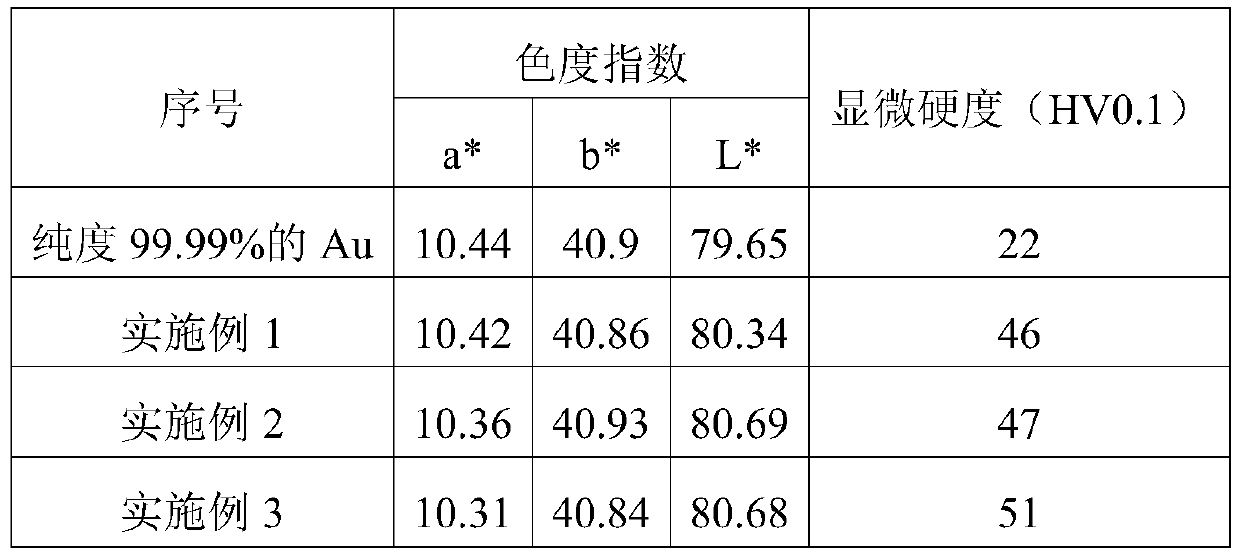

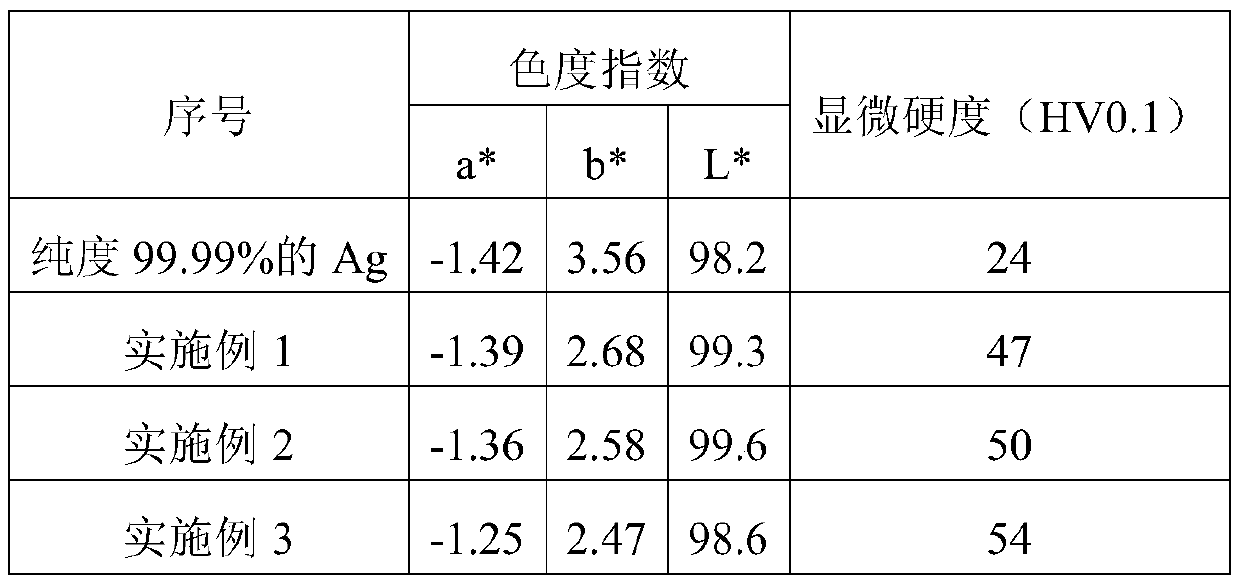

Embodiment 1

[0072] (1) A kind of master alloy that improves pure gold hardness, and this master alloy is prepared from the element of following percentage by weight: Pd powder 10%, Y powder 2%, Ti powder 10%, Cu powder 5%, Si powder 8%, Ge powder 65%, the particle size of the powder is -250 mesh.

[0073] (2) The preparation method of the master alloy described in step (1), the method may further comprise the steps:

[0074] All the above-prepared powders were placed in a three-dimensional mixer and mixed for 3 hours until uniformly mixed to obtain an intermediate alloy.

[0075] (3) Prepare hard pure gold by using the master alloy obtained in step (1) and step (2), as follows (this process is an operation step well known to those skilled in the art):

[0076] a: Take the pure gold raw material with a purity of 99.99% and the master alloy prepared above, and ensure that the pure gold raw material and the master alloy are mixed at a weight ratio of 99.91:0.09;

[0077] b: Make a wax inla...

Embodiment 2

[0086] (1) A kind of master alloy that improves pure gold hardness, and this master alloy is prepared by the element of following percentage by weight: Pd powder 30%, Y powder 5%, Ti powder 12%, Cu powder 3%, Si powder 10%, Ge powder 35%, the particle size of the powder is -250 mesh.

[0087] (2) The preparation method of the master alloy described in step (1), the method may further comprise the steps:

[0088] All the above-prepared powders were placed in a three-dimensional mixer and mixed for 3 hours until uniformly mixed to obtain an intermediate alloy.

[0089] (3) Prepare hard pure gold by using the master alloy obtained in step (1) and step (2), as follows (this process is an operation step well known to those skilled in the art):

[0090] a: Take the pure gold raw material with a purity of 99.99% and the master alloy prepared above, and ensure that the pure gold raw material and the master alloy are mixed at a weight ratio of 99.91:0.09;

[0091] b: Make a wax inlai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com