Laser remanufacturing processing method for automobile stamping die

A technology of laser remanufacturing and stamping dies, which is applied in the direction of metal material coating process and coating, can solve the problems of high loss cost, large heat-affected area, waste of resources, etc., and achieve enhanced corrosion resistance, efficient and rapid cooling, The effect of improving environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

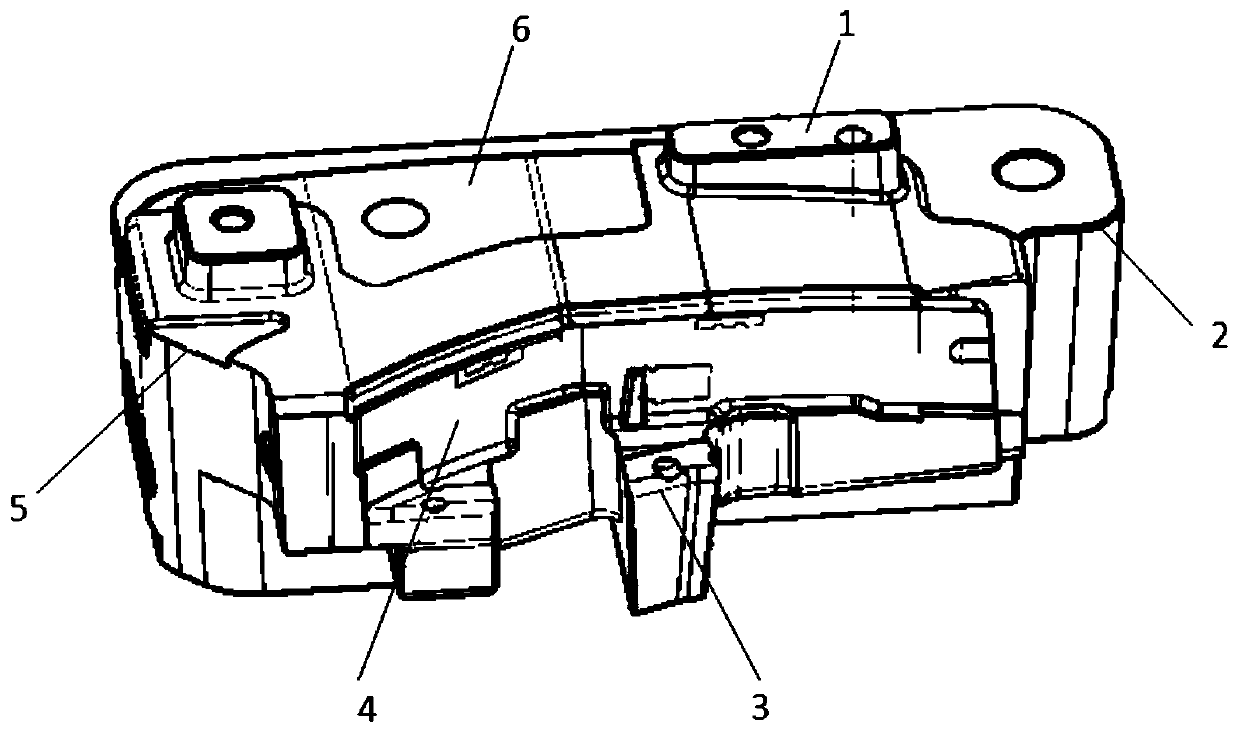

[0042] Method provided by the present invention: as figure 1 As shown, a laser remanufacturing method for an automobile stamping die, the specific steps are as follows:

[0043] Step 1: Pretreat the overall material of the mold to keep it clean and tidy;

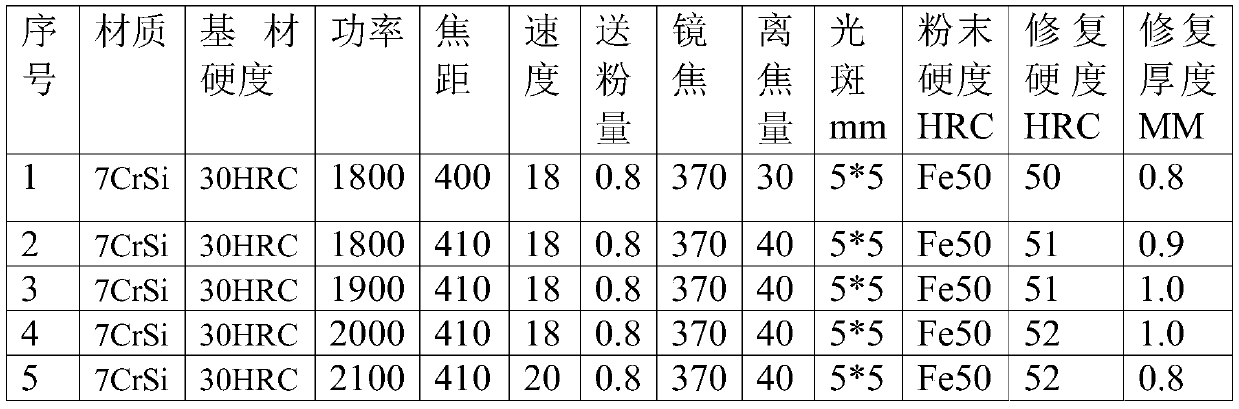

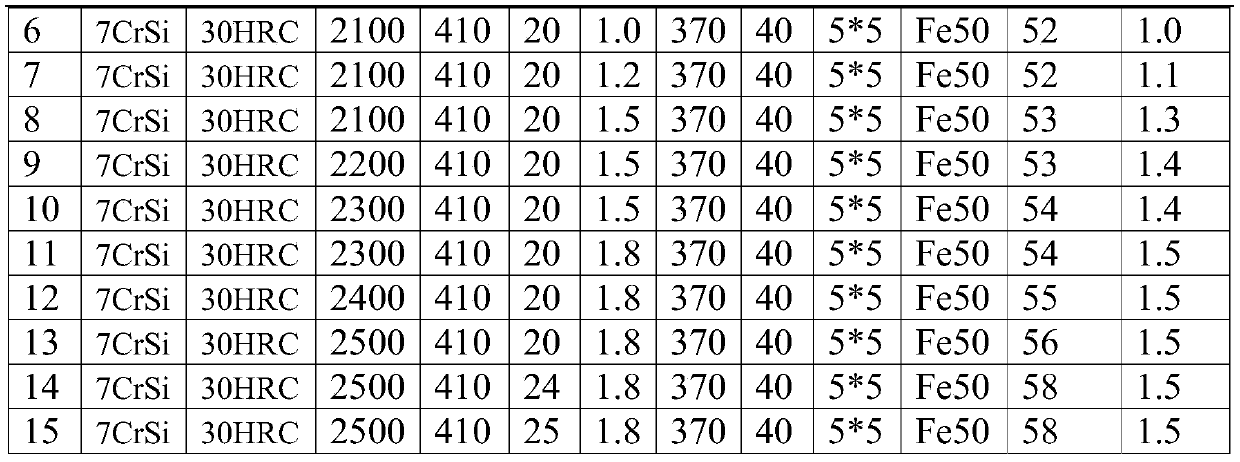

[0044] Step 2: Detect the actual hardness of the base material, and the actual detection base material hardness is HRC30-40;

[0045] Step 3: Select powder for the mold according to the requirements of the working conditions, and start the mixer of the powder feeder to load the powder;

[0046] Step 4: Turn on the gas to test the powder, that is, turn on the switch on the nitrogen bottle, adjust the nitrogen delivery volume so that the delivery value is between 5mbar, adjust the pressure gauge detection value of the powder feeder between 6-8mbar, and start the gas test button;

[0047] Step 5: Start the powder feeding button to focus on the powder, turn on the red light spot of the equipment, and adjust the processing heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com