Construction method of water intaking pipes

A construction method and technology for water intake pipes, applied in water conservancy projects, artificial islands, water supply devices, etc., can solve problems such as inability to guarantee construction quality, expensive machinery and equipment, and inability to isolate water, so as to ensure the quality of welding, shorten the docking time, The effect of ensuring the quality of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means and effects of the present invention for solving technical problems, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the provided accompanying drawings are schematic and mutually exclusive They are not drawn to scale or scale, and therefore the drawings and specific examples are not intended to limit the scope of protection claimed by the invention.

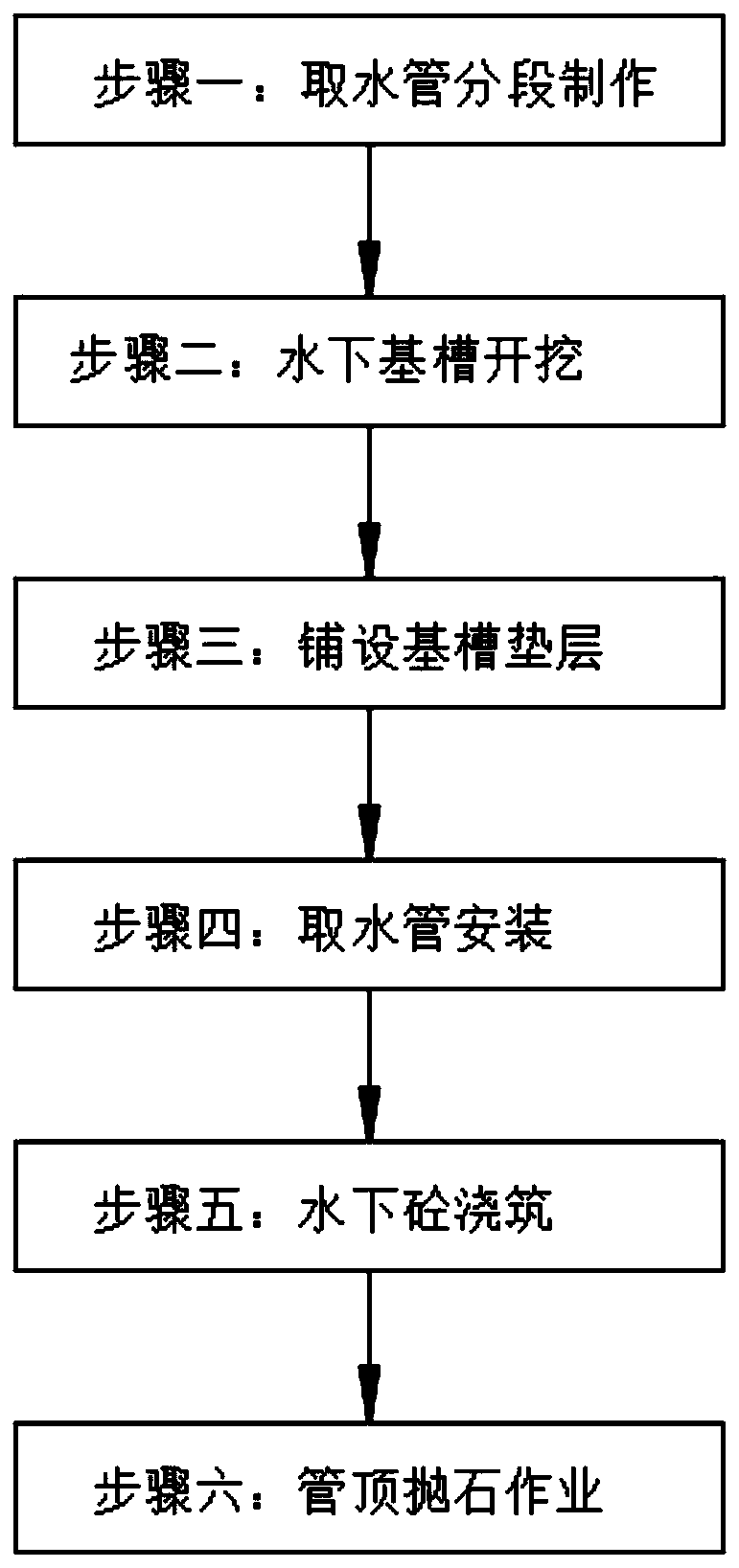

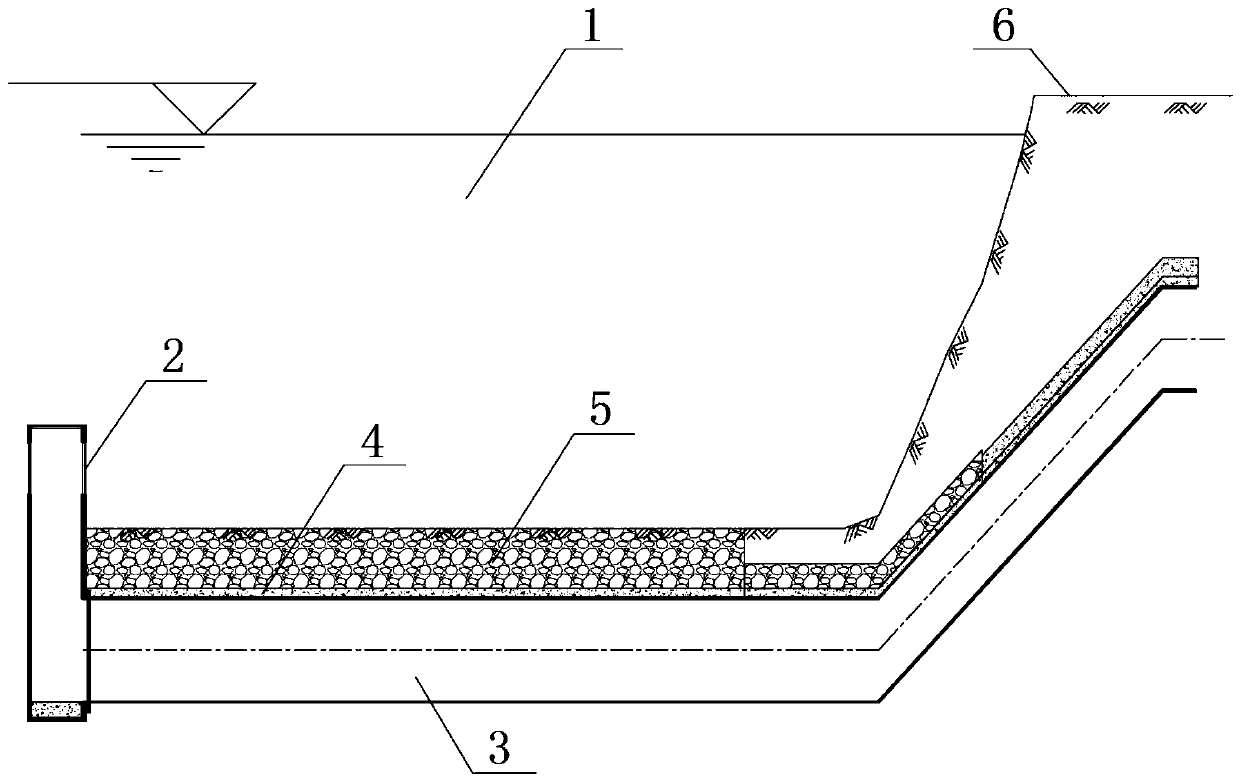

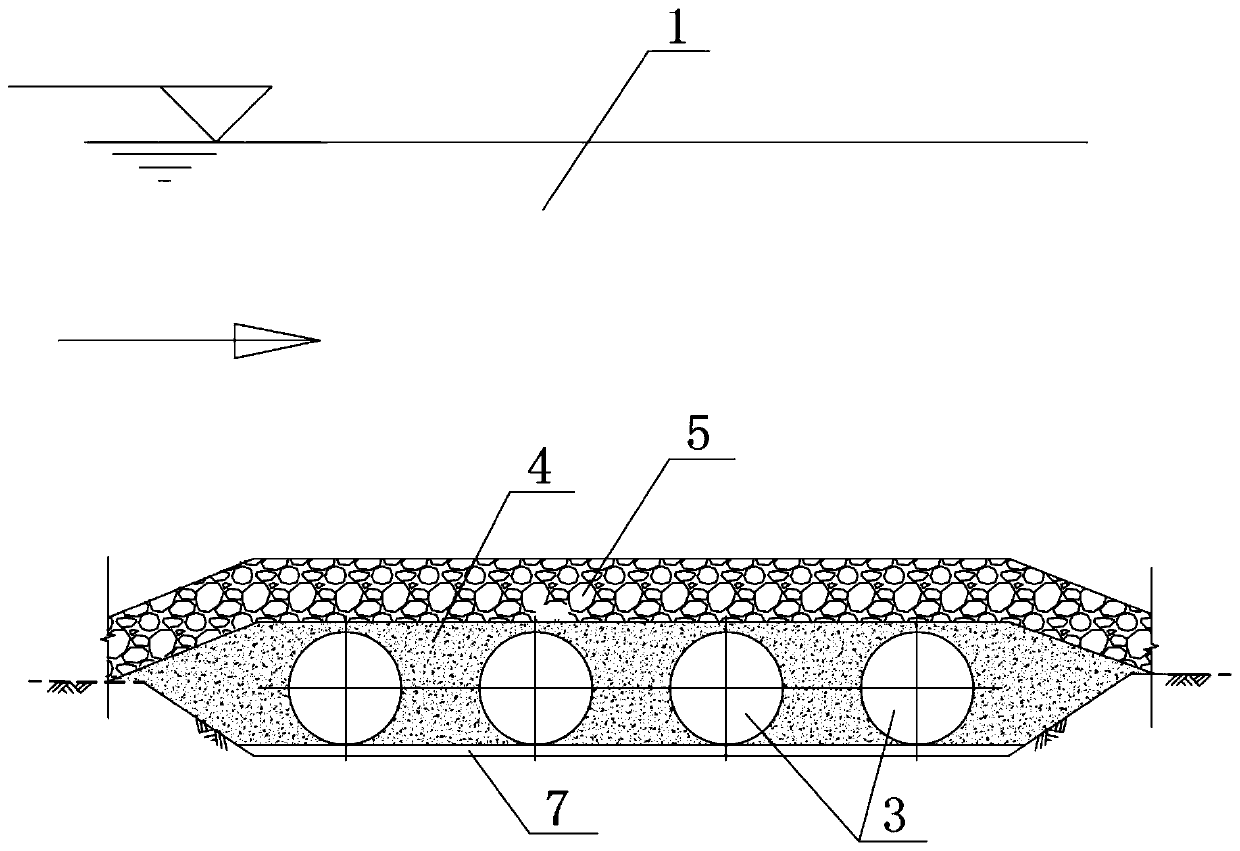

[0026] Such as figure 1 The construction method of the water intake pipe of the present invention shown, carry out figure 2 and image 3 The construction of the shown water intake pipeline includes the following steps:

[0027] Step 1: The water intake pipe 3 is made in sections; the water intake pipe 3 is made of Q235B steel pipe, the outer diameter of the water intake pipe is 3020mm, and the wall thickness is 30mm. To protect the automatic welding process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com