Integrated system equipment for treating drilling oil-based slurry rock debris by cement kiln

An oil-based mud and system equipment technology, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problem of not realizing high-value resource recovery and utilization, and achieve convenient equipment transportation, secondary pollution control, and small equipment modification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

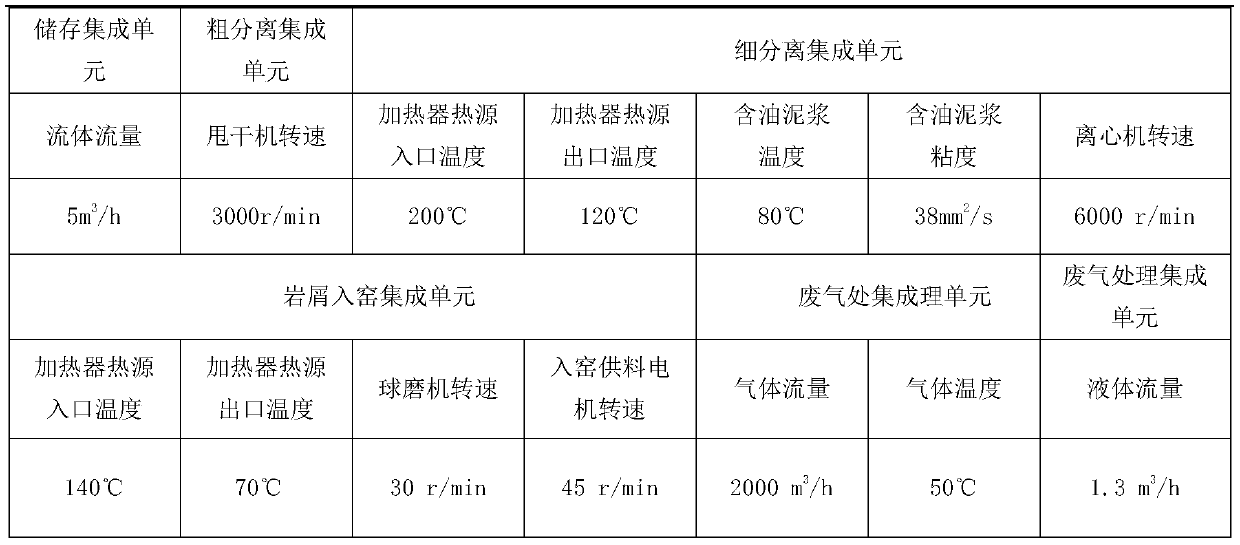

[0037] In this example, the kiln pretreatment unit adopts the cement kiln co-processing drilling oil-based mud cuttings integrated treatment system with dry pretreatment process.

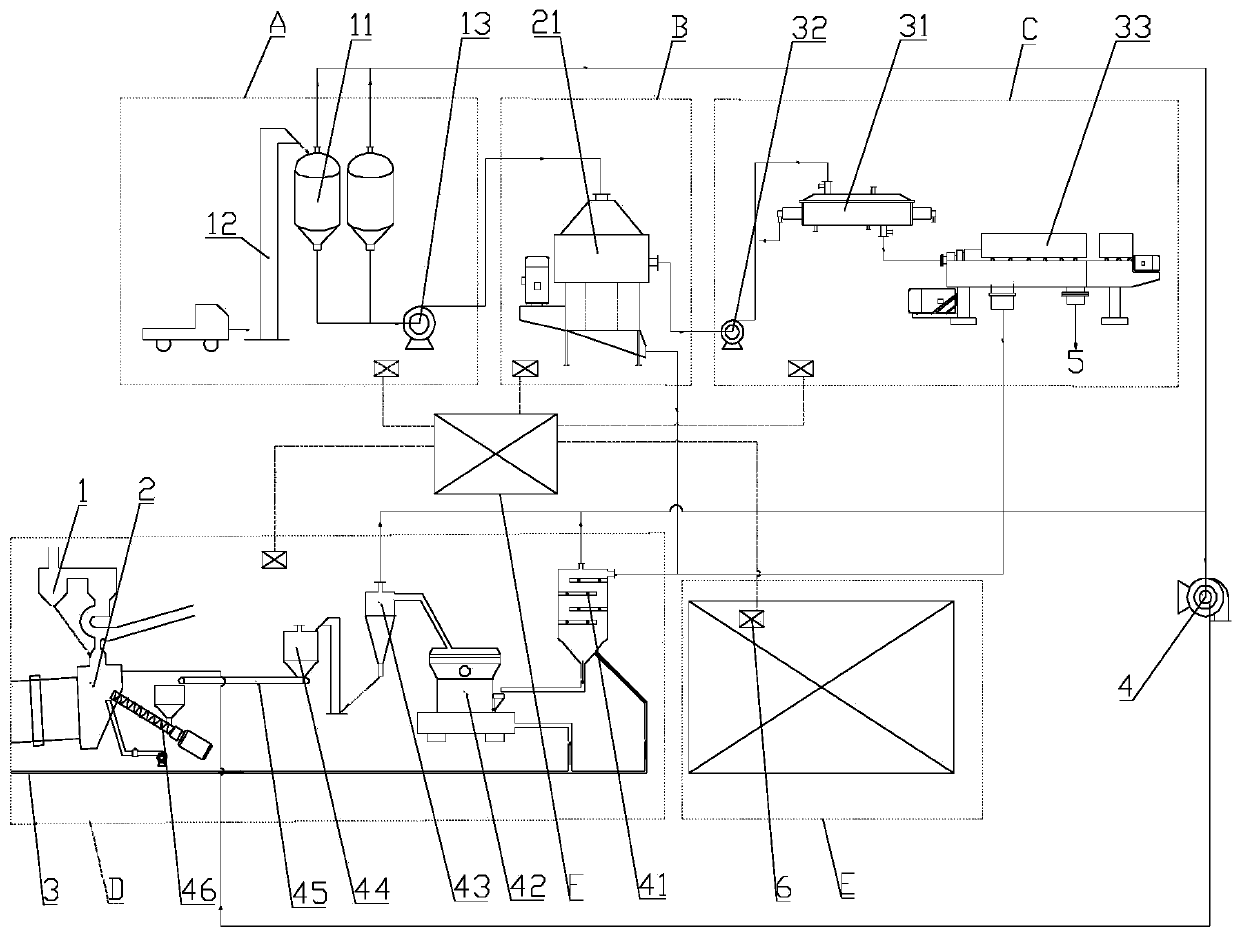

[0038] 1. The integrated processing system for cement kiln cooperative processing of drilling oil-based mud cuttings is composed of the following parts: drilling oil-based mud cuttings storage integrated unit, coarse separation integrated unit, fine separation integrated unit, kiln pretreatment integrated unit, Waste gas treatment integrated unit, waste water treatment integrated unit, integrated control unit.

[0039] 2. Storage of drilling oil-based mud cuttings: cuttings enter the unloading area through special transport vehicles, and are sent to the drilling oil-based mud cuttings storage bin for storage through special equipment; leachate and site flushing of the drilling oil-based mud cuttings storage bin Wastewater, equipment flushing wastewater, and transport vehicle flushing wastewater are ...

Embodiment 2

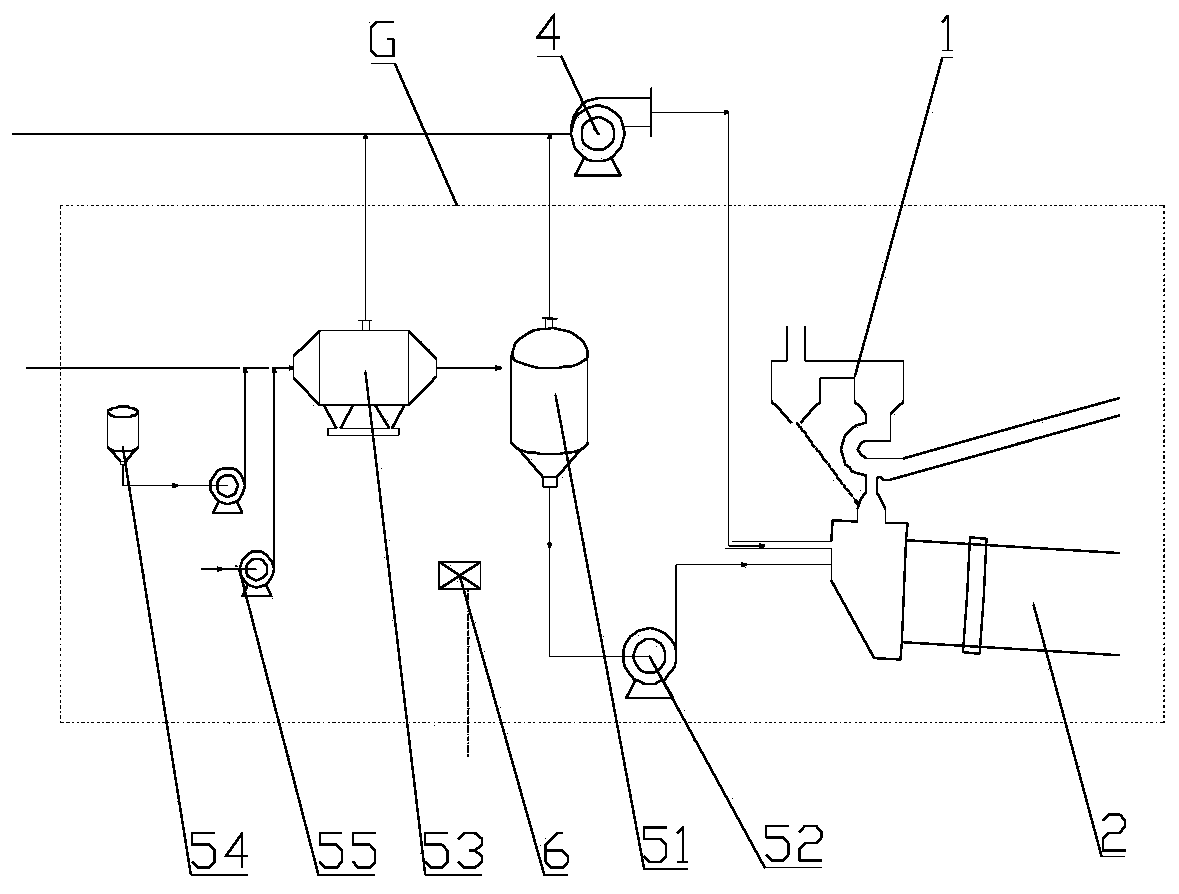

[0054] In this example, the cement kiln cooperative processing drilling oil-based mud cuttings integrated processing system using wet pretreatment process.

[0055] 1. The integrated treatment system for cement kiln co-processing drilling oil-based mud cuttings is composed of the following parts: Drilling oil-based mud cuttings storage integrated unit, kiln pretreatment integrated unit, waste gas treatment integrated unit, wastewater treatment integrated unit, Integrated control unit.

[0056] 2. The storage of drilling oil-based mud cuttings, waste gas treatment integrated unit, wastewater treatment integrated unit, and integrated control unit are the same as the integrated treatment system using dry pretreatment process.

[0057] 3. Kiln pretreatment: Drilling oil-based mud cuttings are sent to wet grinding equipment after adding admixtures and water to grind into a slurry that meets the particle size requirements of the kiln, and the slurry is sent to the slurry homogenizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com