Microbial products and their use in bioremediation and to remove paraffin and other contaminating substances from oil and gas production and processing equipment

A technology for processing equipment and natural gas, applied in the fields of biochemical equipment and methods, microbial determination/inspection, petroleum industry, etc., which can solve problems such as reduced operator output, blocked production of oil pipes and pipelines, improper pump function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] Preparation of Microbial-Based Products

[0129] A microorganism-based product of the invention is simply a fermentation broth containing the microorganisms and / or microbial metabolites and / or any residual nutrients produced by the microorganisms. Fermentation products can be used directly without extraction or purification. Extraction and purification can be readily achieved, if desired, using standard extraction and / or purification methods or techniques described in the literature.

[0130] Microorganisms in microorganism-based products can be in active or inactive form. Microbial based products can be used without further stabilization, preservation and storage. Advantageously, direct use of these microbial-based products maintains high viability of the microorganisms, reduces the possibility of foreign material and unwanted microbial contamination, and preserves the viability of the by-products of microbial growth.

[0131] The microorganisms and / or liquid medium...

Embodiment 1

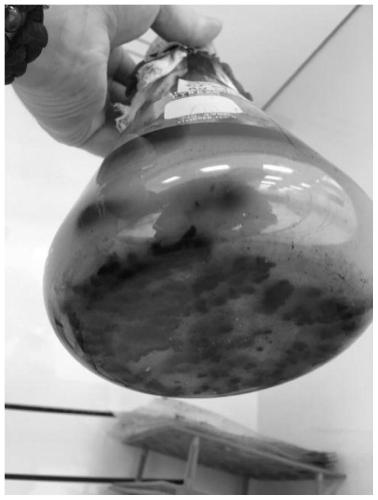

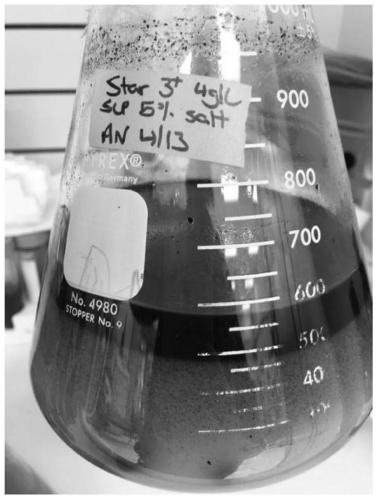

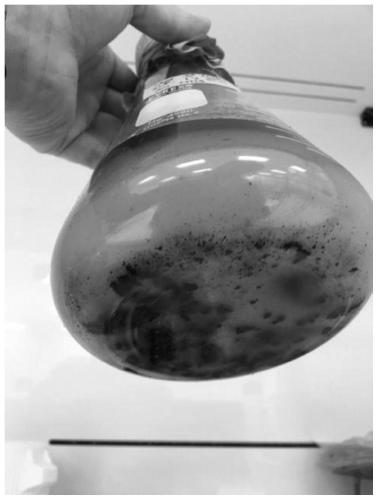

[0245] Example 1 - Liquefaction of Precipitated Asphaltenes Using STAR 3+

[0246] The Star 3+ process of the present invention is used to liquefy refinery fully precipitated and hardened asphaltenes. As shown in Figures 1-6, solutions of Star 3+ (500ml), 4g / L purified SLP and ionic liquid were compared for their ability to liquefy 100g of asphaltene precipitate in a shake flask. like Figure 7 The effectiveness of the Star 3 treatment was also compared to that of the Star 3+ as shown.

[0247] As shown in Figure 8, the flask was subjected to shaking for 5 hours, and then the amount of asphaltene precipitated was measured.

Embodiment 2

[0248] Example 2 - Example protocol for fermenting bioemulsifying yeast

[0249] A nutrient medium comprising two carbon sources is used to grow yeast of eg the Wickhamia, Pichia and / or Starmerella clades. The first carbon source is a sugar such as dextrose or glucose at a concentration of 20 to 50 g / L. The second carbon source is a hydrophobic carbon source such as purified canola oil or vegetable oil at a concentration of 50 to 100 g / L.

[0250] Nitrogen sources such as urea or ammonium salts are also added, as well as sources of magnesium, phosphate and potassium.

[0251] Fermentation occurs for 1 to 5 days. Final concentrations of yeast that can be obtained range from about 500 million to 2.5 billion CFU / mL.

[0252] Example 3 - Fermentation of Candida globosa for Sophoryl ester (SLP) production in a 110 L reactor

[0253] A portable, airlift fully enclosed reactor operated by a PLC with water filtration, temperature control unit and on-board blower was used. When gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com