Invar and aluminum alloy dissimilar metal electron beam welding method

A technology of electron beam welding and Invar alloy, applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of large difference in linear expansion coefficient and chemical properties between tile alloy and aluminum alloy, high stress intermetallic compound, Reduce problems such as joint mechanical properties, achieve the effects of reducing mismatch, reducing complexity, and inhibiting post-weld cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

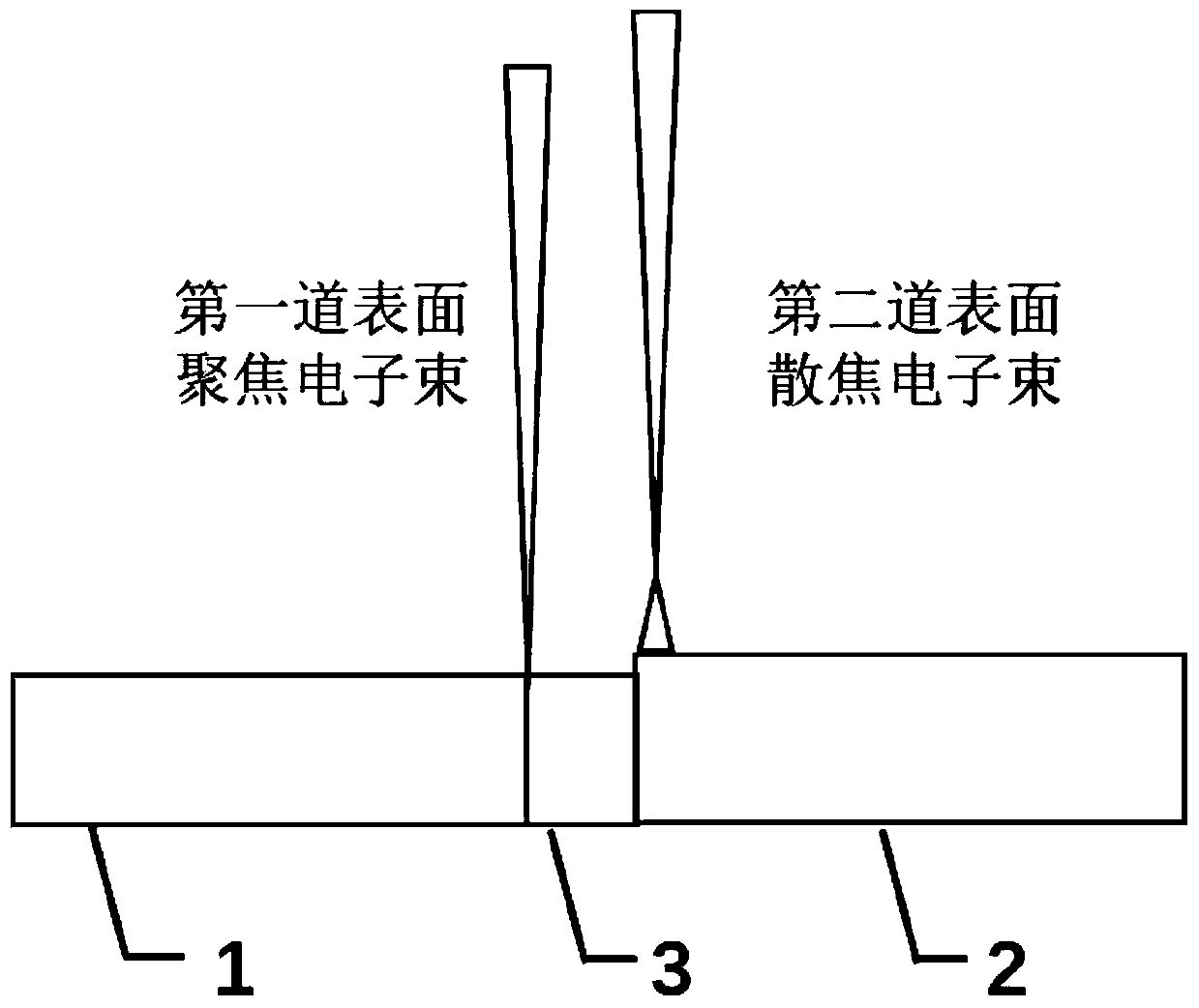

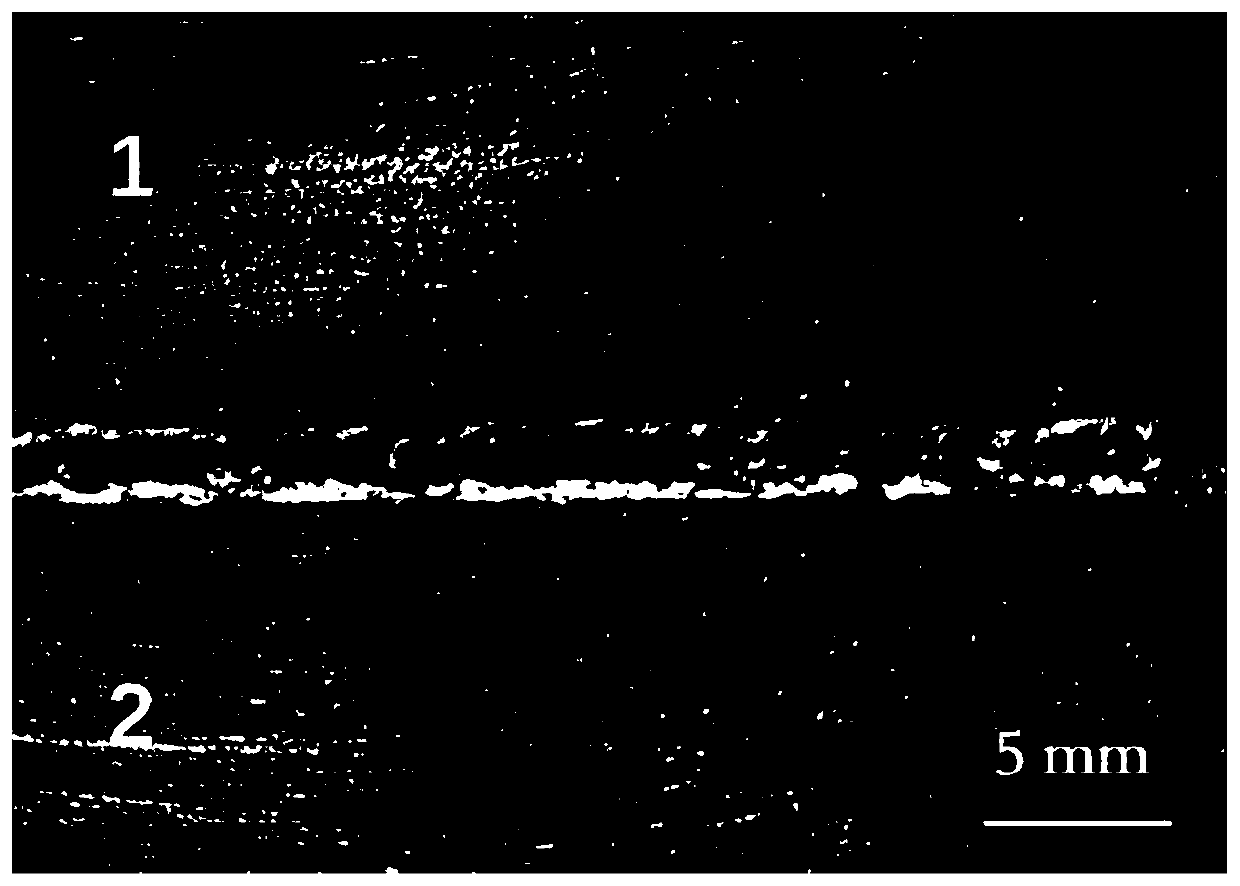

Embodiment 1

[0058] The electron beam butt joint test was carried out on the Invar alloy with a thickness of 2mm and the aluminum alloy with a thickness of 4mm. The middle layer of steel is cut into strips of 50mm×10mm×2mm, and the base material and the middle layer are polished with No. 200 sandpaper until they are bright. Ultrasonic cleaning equipment is used to clean and remove oil stains in industrial alcohol. After drying in a clean drying cabinet, the middle layer is butted with Invar and put into a vacuum chamber. Surface focusing is used during spot welding, spot solid beam current is 1mA, spot solid position interval is 5mm, acceleration voltage is 60kV, surface focusing is used for formal welding, welding speed is 480mm / min, electron beam current is 6mA, and it is cooled in a vacuum chamber after welding After 5 minutes, open the vacuum chamber and take out the welded components. Use wire cutting to cut the side of the middle layer between the welded Invar alloy and the middle ...

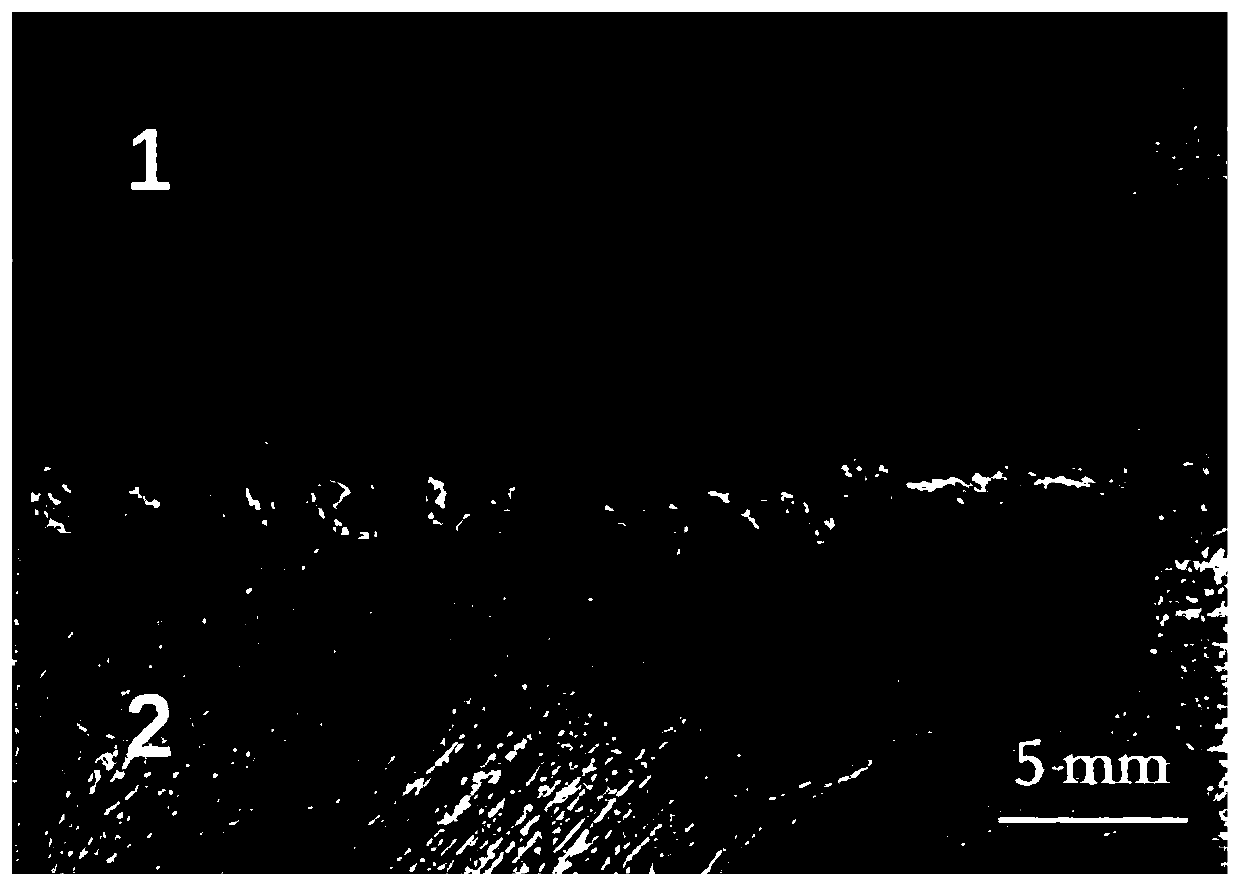

Embodiment 2

[0060] The electron beam butt joint test was carried out on the Invar alloy with a thickness of 3mm and the aluminum alloy with a thickness of 5mm. The middle layer of steel is cut into strips of 50mm×10mm×3mm, and the base material and the middle layer are polished with No. 200 sandpaper until they are bright. Ultrasonic cleaning equipment is used to clean and remove oil stains in industrial alcohol. After drying in a clean drying cabinet, the middle layer is butted with Invar and put into a vacuum chamber. Surface focusing is used during spot welding, spot solid beam current is 1mA, spot solid position interval is 5mm, acceleration voltage 60kV is used for formal welding, surface focusing is used, welding speed is 480mm / min, electron beam current is 8mA, and it is cooled in a vacuum chamber after welding After 5 minutes, open the vacuum chamber and take out the welded components. Use wire cutting to cut the side of the middle layer between the welded Invar alloy and the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com