Transparent flame retardant organic glass plate and preparation method thereof

A plexiglass plate and transparent technology, applied in the field of transparent flame retardant plexiglass plate and its preparation, can solve the problems of poor flame retardant effect, low limit oxygen index, and difficulty in forming flame retardant effect by flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

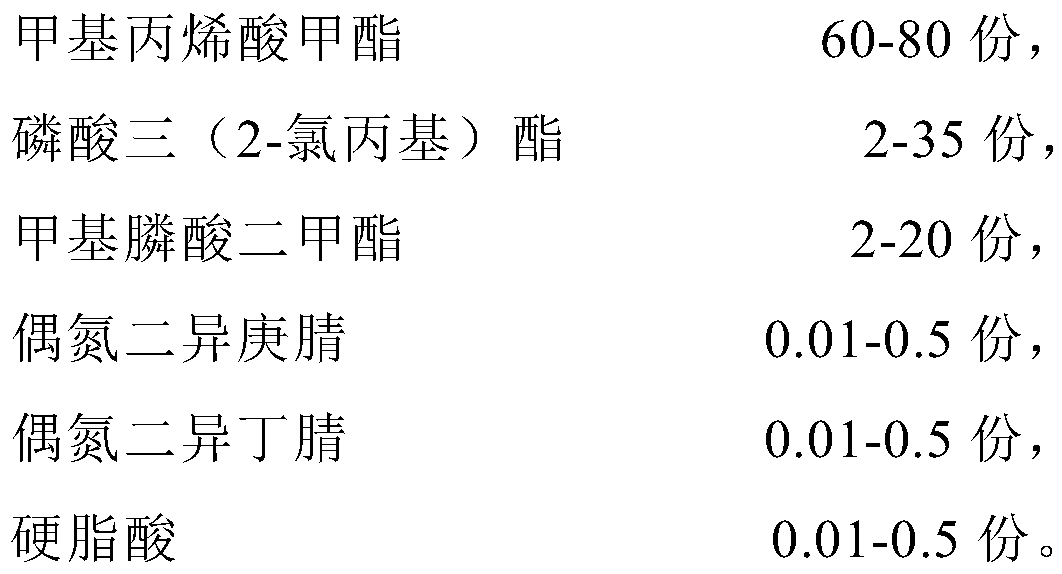

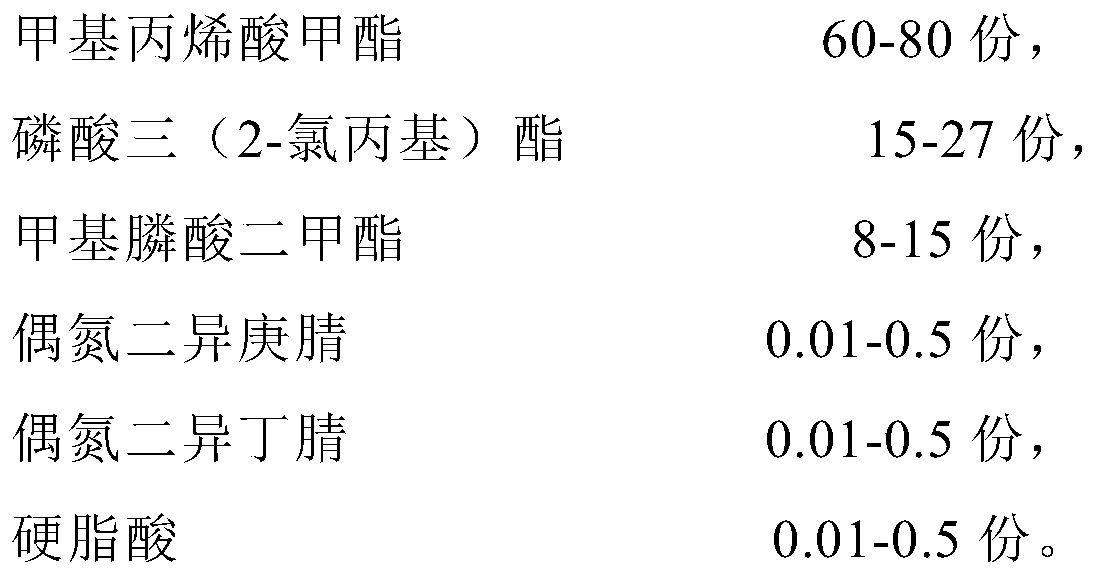

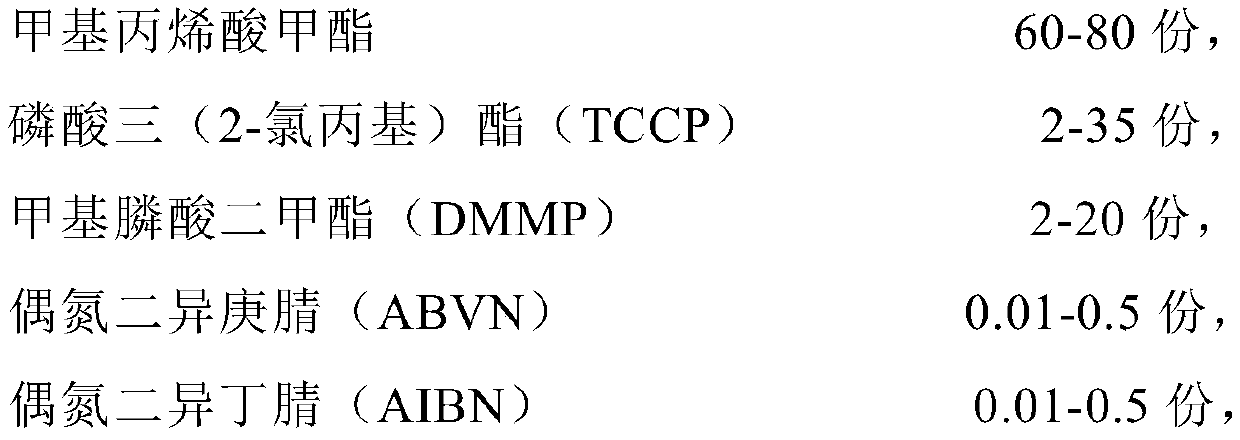

Method used

Image

Examples

Embodiment 1

[0032] A transparent plexiglass flame-retardant board, made of the following raw materials in parts by weight: 72 parts of methyl methacrylate, 19 parts of tris(2-chloroethyl) phosphate, 10 parts of dimethyl methyl phosphonate, 0.03 parts of ABVN initiator, 0.2 parts of AIBN initiator, and 0.3 parts of stearic acid release agent.

[0033] The preparation steps are as follows:

[0034] Step 1, take 72 parts of methyl methacrylate monomer and 0.03 part of ABVN initiator in a beaker and stir and heat;

[0035] Step 2. After the system boils, turn off the heating device and keep stirring for 30 minutes;

[0036] Step 3. After the viscosity of the system reaches 70s, take it out and cool down naturally;

[0037] Step 4. When the system cools down to 27-33°C, add 0.2 parts of AIBN initiator, 0.3 parts of release agent, 19 parts of tris(2-chloropropyl) phosphate, 10 parts of methylphosphonic acid bis Methyl ester, stirred at room temperature for 20 minutes;

[0038] Step 5. Pour ...

Embodiment 2

[0042] A transparent flame-retardant plexiglass plate, made of the following raw materials in parts by weight: 78 parts of methyl methacrylate, 19 parts of tris(2-chloropropyl) phosphate, 10 parts of dimethyl methyl phosphonate, 0.05 parts of ABVN initiator, 0.5 parts of AIBN initiator, and 0.4 parts of stearic acid release agent.

[0043] The preparation steps are as follows:

[0044] Step 1, get 78 parts of methyl methacrylate monomer and 0.05 part of ABVN initiator and stir and heat in a beaker;

[0045] Step 2. After the system boils, turn off the heating device and keep stirring for 30 minutes;

[0046] Step 3. After the viscosity of the system reaches 69-72s, take it out and cool down naturally;

[0047] Step 4. When the system cools down to 27-33°C, add 0.5 parts of AIBN initiator, 0.4 parts of release agent, 19 parts of tris(2-chloropropyl) phosphate, 10 parts of methylphosphonic acid bis Methyl ester, stirred at room temperature for 20 minutes;

[0048] Step 5. Po...

Embodiment 3

[0052] A transparent flame-retardant plexiglass plate is made of the following raw materials in parts by weight: 72 parts of methyl methacrylate, 15 parts of tris(2-chloroethyl) phosphate, 10 parts of dimethyl methyl phosphonate, 0.04 parts of ABVN initiator, 0.3 parts of AIBN initiator, and 0.4 parts of stearic acid release agent.

[0053] The preparation steps are as follows:

[0054] Step 1, get 72 parts of methyl methacrylate monomer and 0.04 part of ABVN initiator and stir and heat in a beaker;

[0055] Step 2. After the system boils, turn off the heating device and keep stirring for 40 minutes;

[0056] Step 3. When the viscosity of the system reaches 71s, take it out and cool down naturally;

[0057] Step 4. When the system cools down to 27-33°C, add 0.3 parts of AIBN initiator, 15 parts of tris(2-chloropropyl) phosphate, 10 parts of dimethyl methylphosphonate, and mold release agent to the system 0.4 parts, stirred at room temperature for 40 minutes;

[0058] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com