Diamond wire cutting liquid and preparation method and application thereof

A technology of diamond wire cutting and raw materials, applied in the petroleum industry, lubricating compositions, etc.

Active Publication Date: 2019-10-01

SHANGHAI SINYANG SEMICON MATERIALS

View PDF13 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The purpose of the present invention is to overcome the defects of cutting fluid in the prior art, such as dispersibility of chips, cutting accuracy, wettability, defoaming property or friction coefficient, and to provide a diamond wire cutting fluid and its preparation method and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

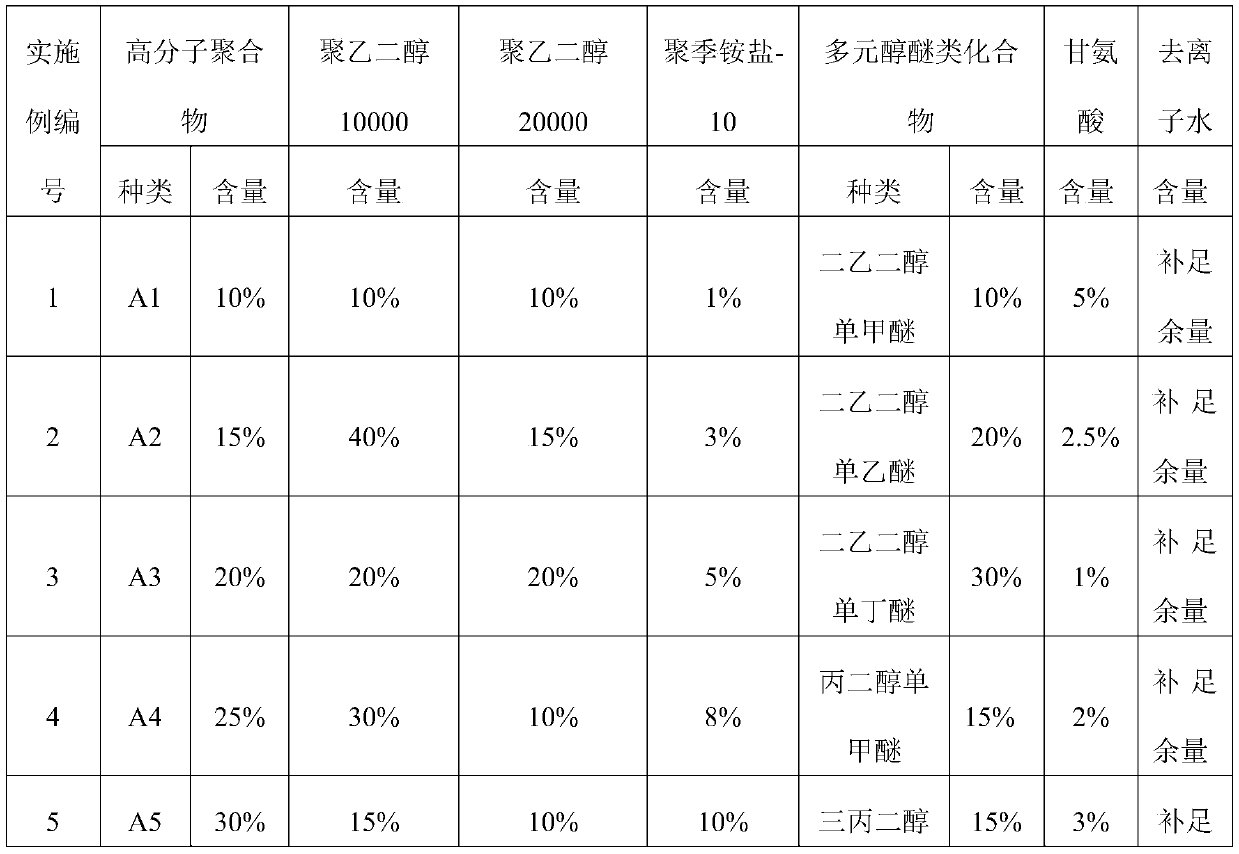

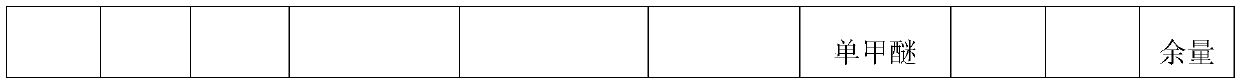

Embodiment 1~5

[0085] Table 1

[0086]

[0087]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a diamond wire cutting liquid and a preparation method and application thereof. The diamond wire cutting liquid is prepared from, by mass percentage, 10-30% of a high molecularpolymer, 10-40% of polyethylene glycol 10000, 10-20% of polyethylene glycol 20000, 1-10% of polyquaternium-10, 10-30% of a polyol ether compound, 1-5% of glycine and the balance water, wherein the percentage is the mass percentage of each component in the total mass percentage of all the components, and the high molecular polymer is polyethylene glycol modified hyperbranched polyether ester. Thediamond wire cutting liquid has good comprehensive performance.

Description

technical field [0001] The invention relates to a diamond wire cutting fluid and its preparation method and application. Background technique [0002] At present, there are two main ways to cut silicon wafers: one is free abrasive cutting, and the other is fixed abrasive cutting. Among them, the free abrasive method tends to be gradually eliminated, and its existing problems include: when the steel wire is thick, the cutting loss becomes larger. Therefore, when cutting silicon wafers, a large amount of cutting powder is produced, the product yield is low when cutting silicon ingots, and there is a limit to the thinning of steel wires. The fixed abrasive cutting method is more and more widely used because of its ability to make steel wire thinner, reduce cutting powder, and have higher yield. [0003] In order to improve product yield, higher and higher requirements are put forward for the diamond wire cutting fluid with fixed abrasives: for example, to reduce the friction ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10N30/12C10N30/16C10N30/18C10N30/06

CPCC10M173/02C10M2207/046C10M2209/104C10M2209/109C10M2215/04C10M2217/022C10M2217/028C10M2217/06C10N2030/06C10N2030/12C10N2030/16C10N2030/18

Inventor 方书农蔡进马雪彦黄卫东

Owner SHANGHAI SINYANG SEMICON MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com