Y type metal water stop structure and water pool base plate and guide wall waterproof construction method

A construction method and technology of water-stop boards, which are applied to swimming pools, building components, building types, etc., can solve the problems of water leakage in pools, achieve simple construction procedures, save time and costs, and reduce the possibility of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

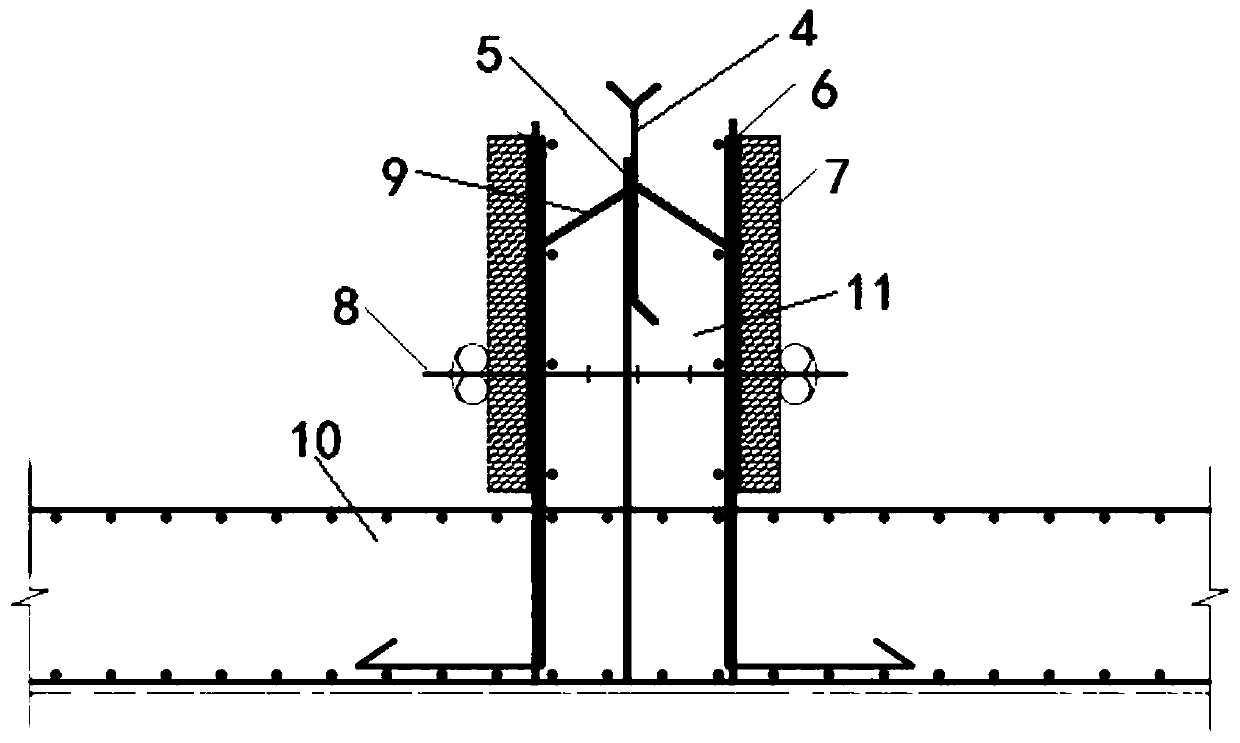

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Due to the high height of the pool in the large-scale electronic clean workshop and the high pressure at the bottom of the pool, a guide wall 11 needs to be set up according to the design requirements, and the construction joint should be left at a position where the structure is subject to less shear force and is convenient for construction. Therefore, a transverse construction joint is formed on the pool wall, and the water stop structure described in the present invention is used for the transverse construction joint between the guide wall 11 of the pool and the pool wall.

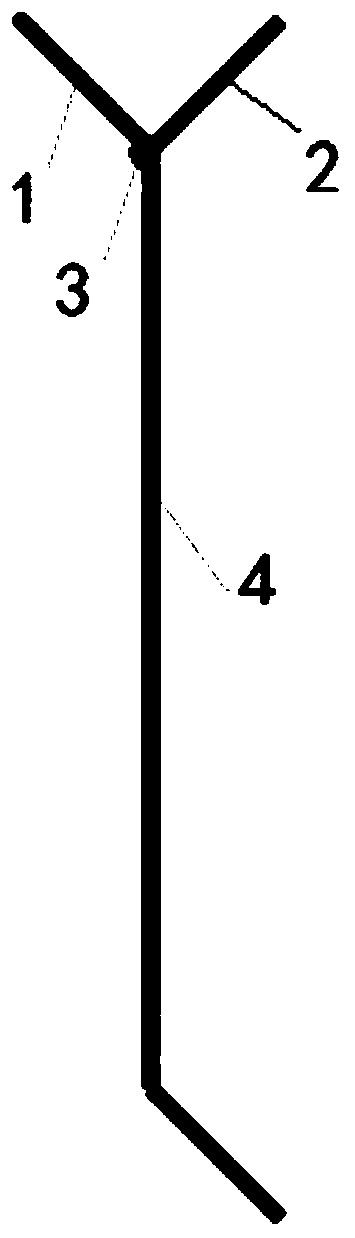

[0024] like figure 1 A Y-shaped metal water-stop structure shown includes a water-stop main body 4, the upper end of the water-stop main body 4 is provided with a first sub-water-stop 1 and a second sub-water-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com