A broadband damping and vibration reduction modular water-lubricated bearing

A water-lubricated bearing, modular technology, applied in sliding contact bearings, bearings, flexible bearings, etc., can solve the problem of little application research on vibration reduction and noise reduction of water-lubricated stern bearings, and achieve low maintenance costs and improved comfort. , Improve the effect of vibration reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

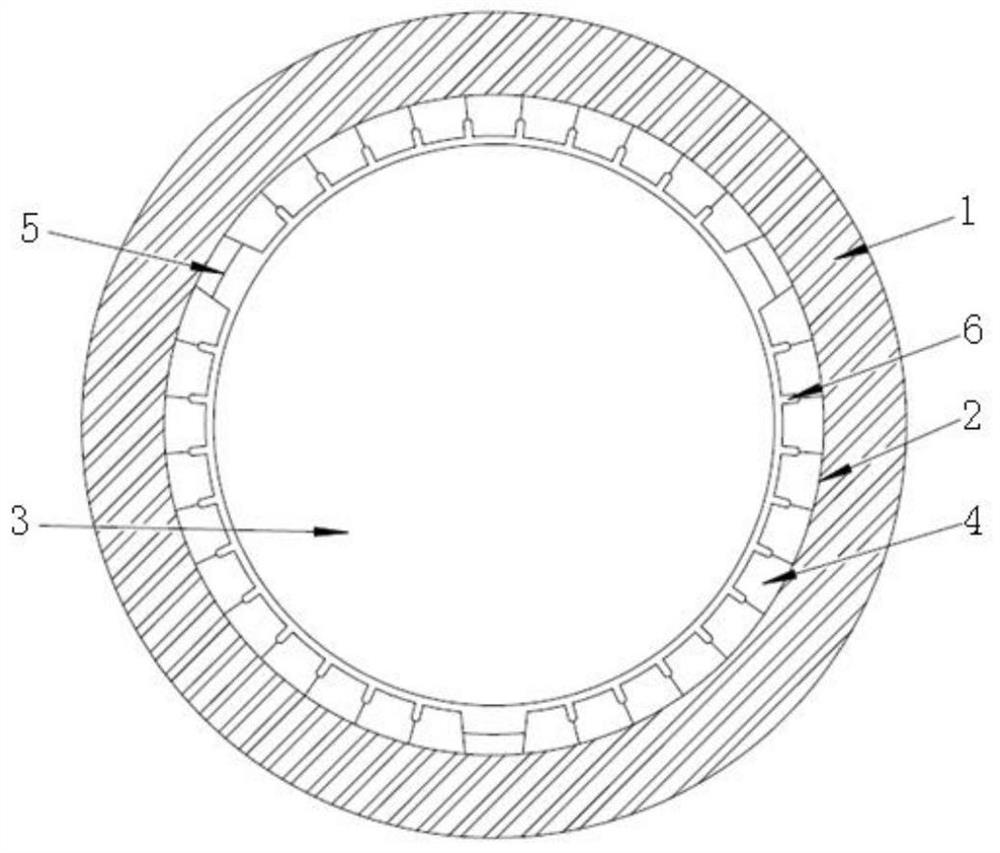

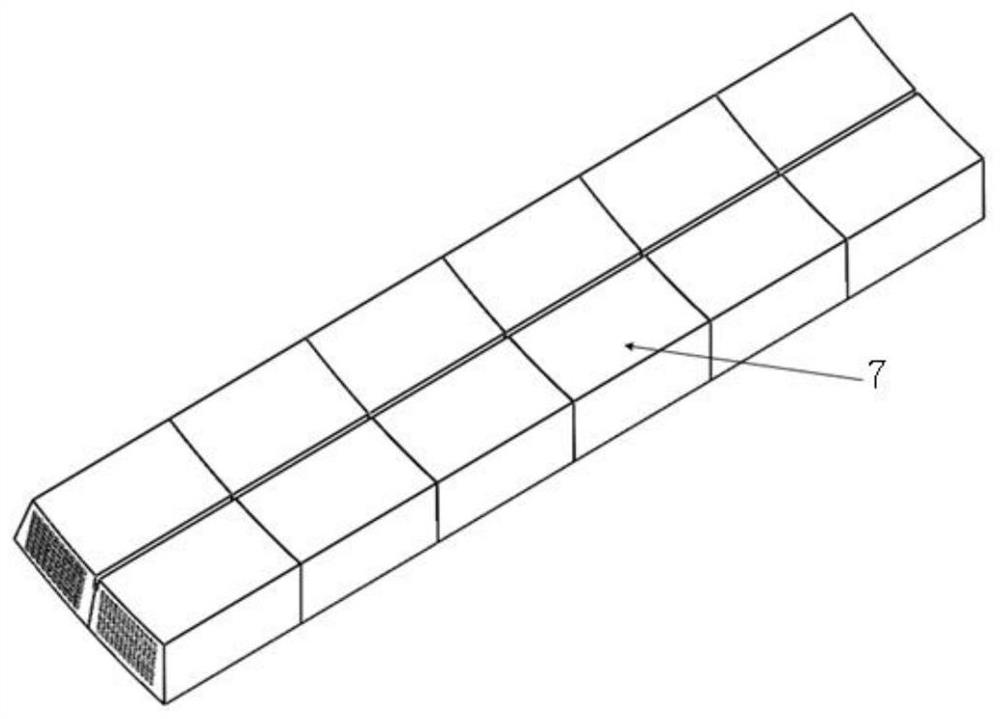

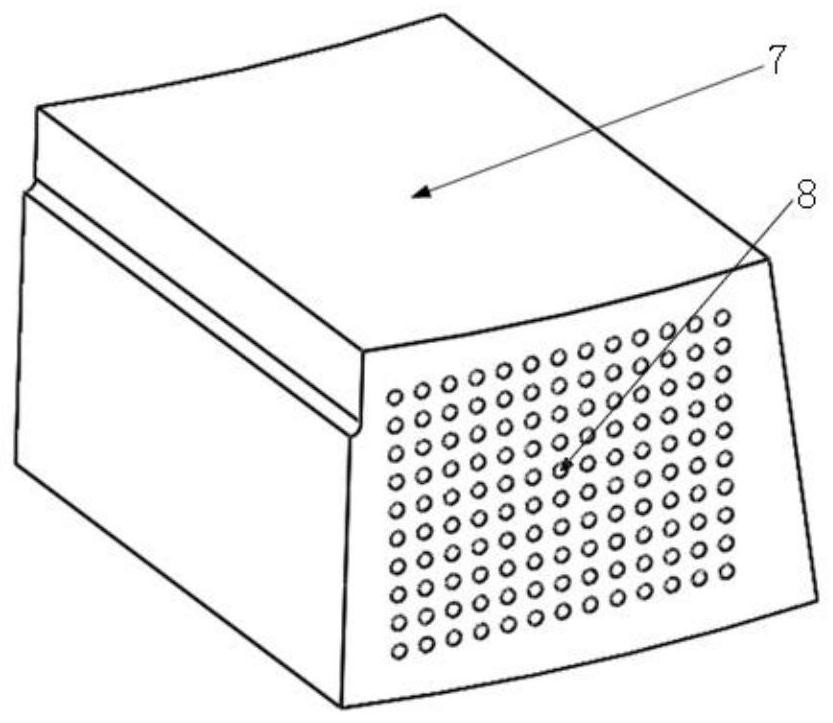

[0029] Multiple damping modules are evenly spaced, and there is a gap between two adjacent damping modules. Axial through holes 8 are evenly distributed on the damping modules. The axial through holes on multiple damping modules can correspond one by one to form through holes. , and may not correspond to penetration. When the main shaft rotates at different speeds, vibration and noise of different frequencies will be generated. When the vibration radially passes through the tail bearing slats, the vibration energy will be reduced. Compared with the slats without axial through holes, when the vibration energy enters Part of the axial through hole will be consumed, so the vibration energy that can pass through the inner bushing will be further reduced, which can absorb noise and attenuate vibration to a certain extent (see Figure 4 and Figure 7 ). The water in the gap between the damping modules will flow when the main shaft rotates, forming a fluid-solid coupling. Under the...

Embodiment 2

[0031] A plurality of damping modules are installed with interference fit, and axial cavities are evenly distributed on the damping modules, and fluids, such as silicone oil, etc. are injected into the axial cavities. When the main shaft rotates, the silicone oil in the holes is generated under external excitation. Vibration, friction with the wall, using the enhanced damping effect of the fluid-solid coupling area to attenuate the transmission of vibration.

Embodiment 3

[0033] The interference fit between multiple damping modules is installed. The first and last two damping modules are solid structures. The middle damping module is evenly distributed with axial through holes. Water enters the axial through holes. When the main shaft rotates, the water in the holes is excited by the outside world. Vibration is generated under the action, friction with the wall surface, and the damping effect enhanced by the fluid-solid coupling area is used to attenuate the transmission of vibration.

[0034] The structure of the arrangement of the axial through holes is different, and the natural frequency is different. The damping modules with different arrangement structures can reduce vibration and noise at different frequencies. Due to the gravity of the main shaft, there will be an eccentric load, mainly the lower part bears the load, so in order to meet the rigidity requirements, the lower part of the bearing uses a rubber damping module with a smaller m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com