A device and method for detecting polyvinyl alcohol content in microsphere preparations

A technology of polyvinyl alcohol and microspheres, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of accurate and quantitative analysis of infinitely small amounts of polyvinyl alcohol content, etc., and achieve the effect of low detection limit, good repeatability and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

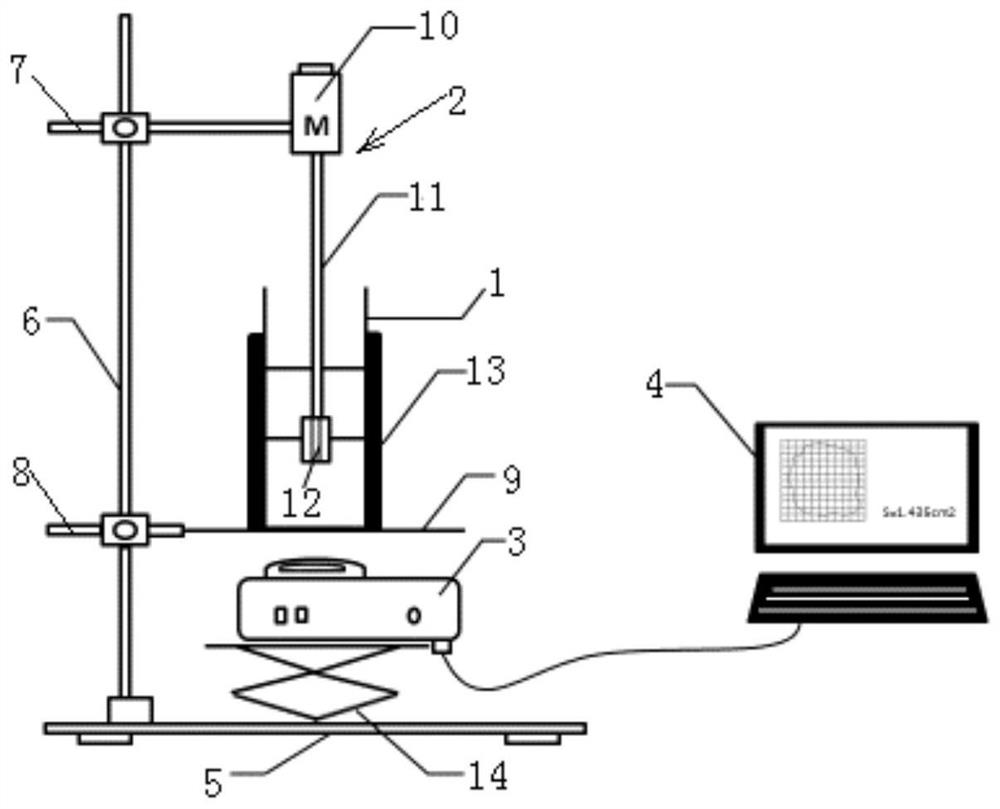

[0047] Such as figure 1 As shown, the present invention provides a kind of device that detects polyvinyl alcohol content in microsphere preparation, comprises: transparent container 1, is used to hold microsphere preparation and organic solvent-water system; Emulsifier 2, is used to hold in The microsphere preparation and the organic solvent-water system in the transparent container 1 are emulsified; the image collector 3 is used to capture the outline of the liquid film after the emulsification treatment; the image processor 4 is connected to the image collector 3 and used to receive the liquid film Contour, calculate the contour area of the liquid film, and calculate the polyvinyl alcohol content in the microspheres according to the area-concentration standard curve of the emulsified liquid film formed by the known concentration of polyvinyl alcohol.

[0048] A further technical solution is that the transparent container 1, the emulsifier 2 and the image collector 3 are su...

Embodiment 2

[0055] (1) Weigh 100mg of leuprolide acetate microspheres into a transparent container, add 30ml of organic solvent dichloromethane-water system (1:1), turn on the emulsifier to 3000rpm, homogenize until the microspheres are completely dissolved, and obtain Transparent layered two-phase solution, constant temperature to 25°C;

[0056] (2) Turn on the emulsifier to 10000rpm and emulsify for 2 minutes. After the residual polyvinyl alcohol can form stable microemulsion droplets at the water-oil interface, stop the emulsification, remove the emulsifier, and let it stand until the microemulsion droplets form a continuous microemulsion at the water-oil interface. single-layer emulsion liquid film;

[0057] (3) The image collector located under the transparent container captures the contour of the emulsified liquid film from bottom to top at the first time, and transmits it to the image processor through the data line. The image processor uses CAD area software to calculate the area ...

Embodiment 3

[0069] (1) Weigh 50mg of risperidone microspheres into a transparent container, add 30ml of organic solvent dichloromethane-water system (1:1), turn on the emulsifier to 3000rpm, homogenize until the microspheres are completely dissolved, and obtain a transparent fraction layer two-phase solution, constant temperature to 25 ° C;

[0070] (2) Turn on the emulsifier to 10000rpm and emulsify for 2 minutes. After the residual polyvinyl alcohol can form stable microemulsion droplets at the water-oil interface, stop the emulsification, remove the emulsifier, and let it stand until the microemulsion droplets form a continuous microemulsion at the water-oil interface. single-layer emulsion liquid film;

[0071] (3) The image collector located under the transparent container captures the contour and area of the emulsified liquid film from bottom to top at the first time, and transmits it to the image processor through the data line. The image processor uses CAD area software to calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com