Intelligent PIC control system based on cable production control

A technology of production control and control system, applied in general control system, control/adjustment system, electrical program control, etc., can solve time-consuming and laborious problems, reduce production cost, improve production safety factor, and effectively supervise the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

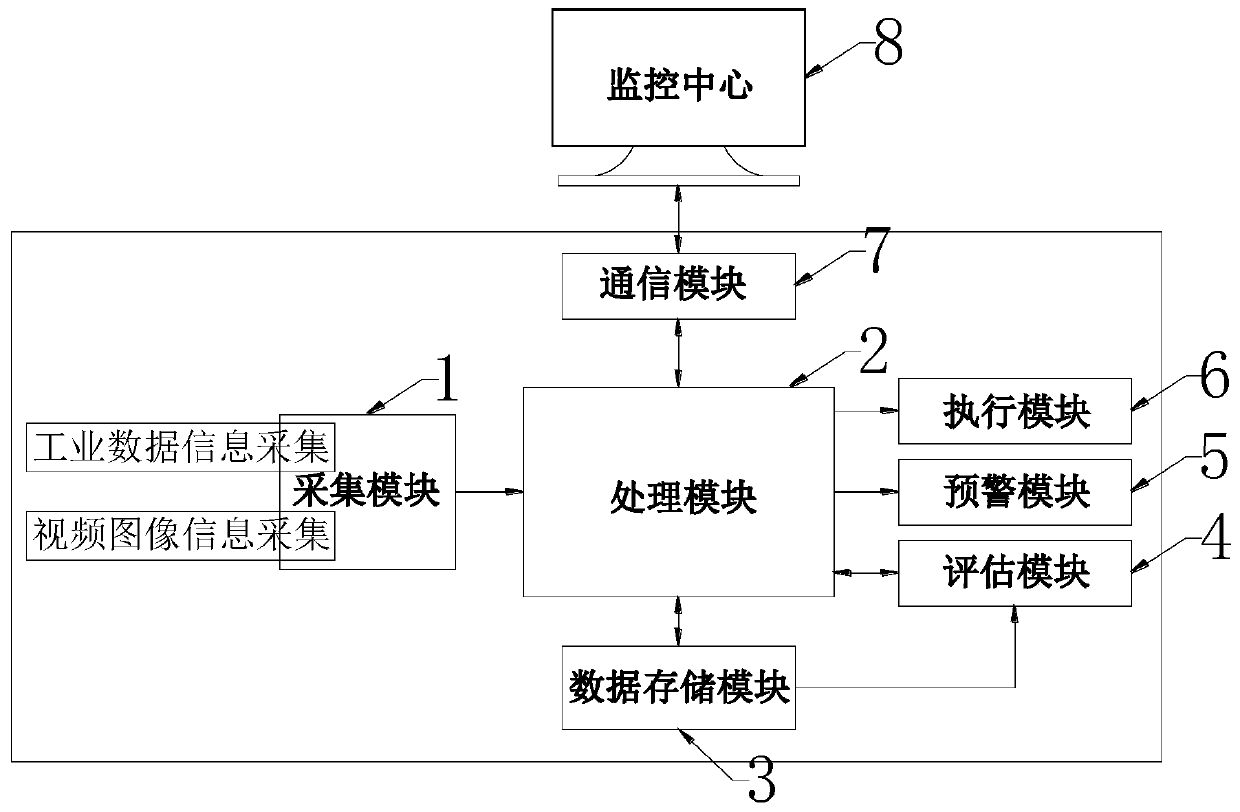

[0031] Such as figure 1 Shown, embodiment one of the present invention is:

[0032] An intelligent PIC control system based on cable production control, including an acquisition module 1, a processing module 2, a data storage module 3, an evaluation module 4, an early warning module 5 and an execution module 6;

[0033] The output end of the acquisition module 1 is connected to the input end of the processing module 2, and the processing module 2 is bidirectionally connected with the data storage module 3 and the evaluation module 4 respectively, and the output end of the processing module 2 Respectively connected with the input end of the early warning module 5 and the input end of the execution module 6, wherein;

[0034] The collection module 1 is used to collect real-time data information and video image data information of the cable production process;

[0035] The processing module 2 is configured to process data information;

[0036] The data storage module 3 is used...

Embodiment 2

[0043] Such as figure 1 Shown, embodiment two of the present invention is:

[0044] An intelligent PIC control system based on cable production control, on the basis of Embodiment 1, the acquisition module 1 includes industrial data information acquisition and video image information acquisition, wherein;

[0045] The industrial data information collection includes the average thickness of the insulating layer, the thickness of the thinnest part of the insulating layer, the thickness of the thickest part of the insulating layer, the degree of insulation eccentricity, the average thickness of the conductor shielding layer, the thickness of the thinnest part of the conductor shielding layer, and the thickness of the insulating shielding layer The average thickness of the insulation shield, the thickness of the thinnest part of the insulation shield, the outer diameter of the wire core, the temperature of the extruder head, and the temperature of the cooling section of the wire c...

Embodiment 3

[0048] Such as figure 1 Shown, embodiment three of the present invention is:

[0049]An intelligent PIC control system based on cable production control, on the basis of the second embodiment, also includes a communication module 7 and a monitoring center 8, the communication module 7 is connected to the processing module 2, and the monitoring center 8 is connected to the The communication module 7 performs signal transmission, the processing module 2 transmits the characteristic information to the monitoring center 8, and the monitoring center 8 transmits instructions through the characteristic information and cooperates with the execution module 6 to complete the instruction.

[0050] With the help of the above scheme, through the communication module 7 and the monitoring center 8, remote monitoring of the production and quality of the cable products is realized without sending technicians to the factory to supervise the manufacturing. It can be more comprehensive and make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com