Fixator of bone and cartilage and using method of fixator

A fixator and cartilage technology, applied in the field of medical equipment, can solve the problems of difficult operation, long time for donor cartilage to recover biomechanical properties, wear of surrounding cartilage, etc., to achieve a stable healing environment, shorten the time to recover biomechanical properties, Simple effect of fixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

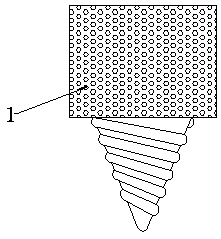

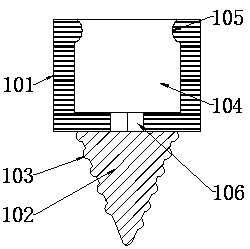

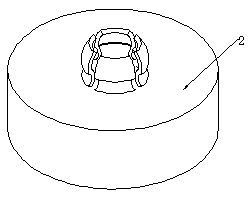

[0038] Embodiment 1 A kind of bone and cartilage fixator

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Commonly shown, the present invention provides a bone and cartilage fixator, including a fixer 1, the fixer 1 is a bracket formed by 3D printing of absorbable medical polymer materials, and the bracket consists of an upper cylinder 101 and a lower cone 102 Composition: The fixer 1 is used to clamp and fix the tissue culture donor 2 .

[0040] The cylinder 101 is cylindrical, with a cylindrical cavity 104 inside. The top of the cavity 104 is open, and an annular protrusion 105 is arranged at the opening; hole; the bottom of the cavity 104 is blocked; the bottom of the cavity 104 is provided with a groove 106, the groove 106 is a "one", "ten" or "m" shape, the purpose of setting the groove 106 Cooperate with the screwdriver to screw the fixture 1; the large-diameter end of the cone 102 is fixedly connected to the blocking end of the cylinder 1...

Embodiment 2

[0044] Embodiment 2 A kind of using method of bone and cartilage fixator

[0045] The invention provides a method for using a bone and cartilage fixator, comprising the following steps:

[0046]Step 1: Obtain the size information of the donor 2 according to the patient’s imaging data, use absorbable medical polymer materials to 3D print out the scaffold of the donor 2, and load the matrix material that induces cartilage regeneration into the scaffold; make the matrix material Create micropores suitable for bone ingrowth; take the patient's bone marrow stromal stem cells and load them into the matrix for chondrogenic induction of stem cells; (1) Only culture cartilage donors: load stem cells in donor 2 and induce culture toward cartilage 8-9 (2) Culture only the cancellous bone donor: Stem cells were loaded into the donor 2 and cultured in the direction of the cartilage for 3 weeks. After implantation, in an environment rich in human blood supply, the donor Turn to grow in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com