Carbon microsphere cleaning device and method

A technology of carbon microspheres and equipment, which is applied in the field of coking, can solve the problems that the centrifuge cannot be operated in a closed manner, reduce the product yield, increase the amount of solvent, etc., and achieve the effect of eliminating the risk of fire and personnel health and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

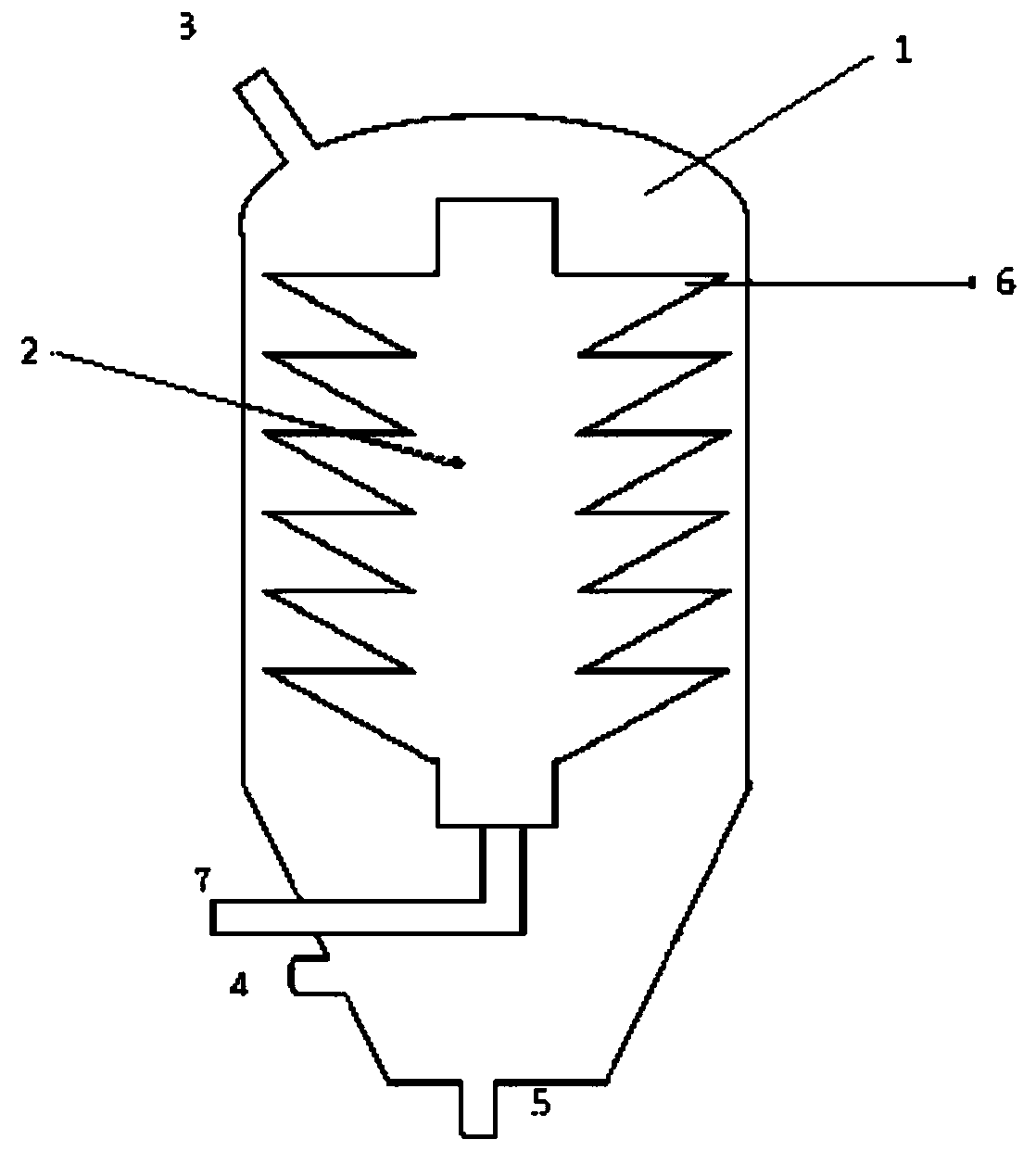

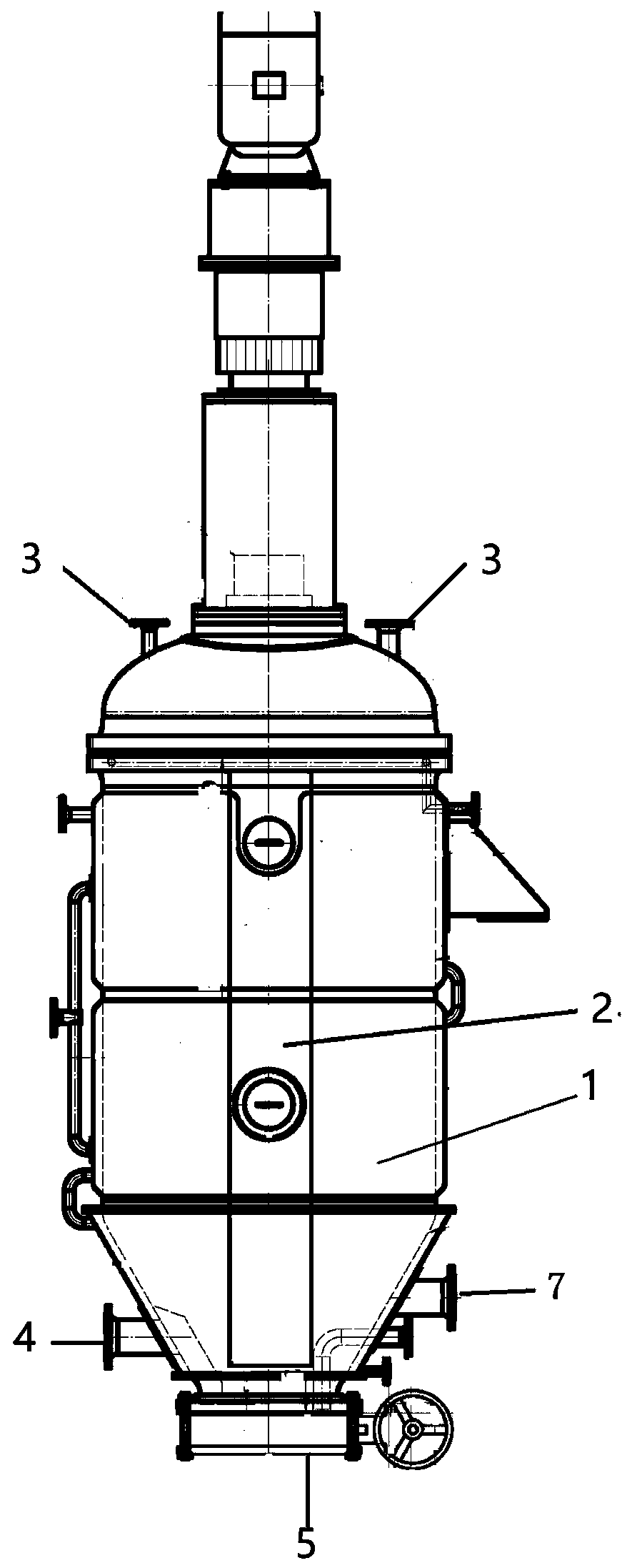

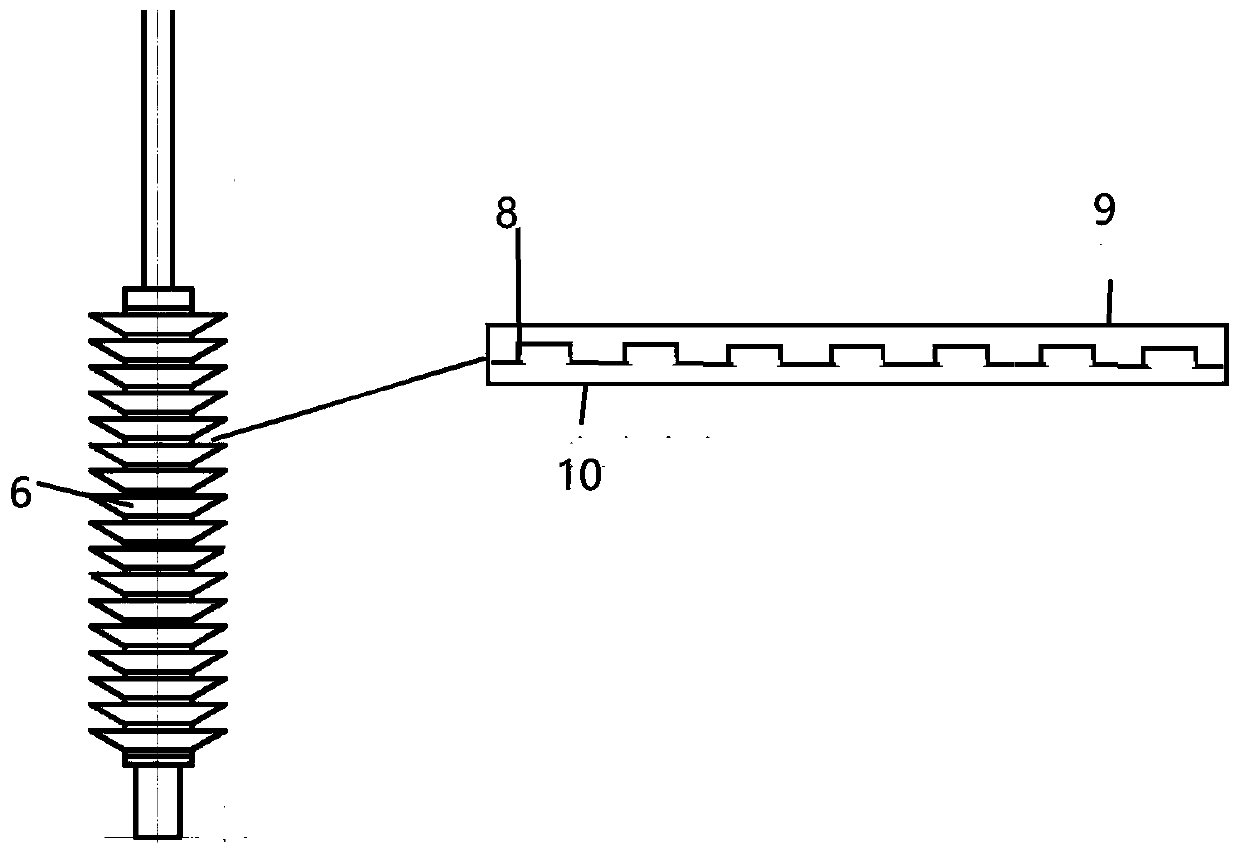

Method used

Image

Examples

Embodiment 1

[0032] Mix 1 ton of carbon microspheres with 3 tons of washing oil, heat to 130°C, and then stir for 2 hours to form a mother liquor. The tank (1) is filled with the mother liquor, and low-pressure steam (0.3MPa) is introduced for pressure filtration, and the liquid is discharged after filtering for 2 hours. Add washing oil at 120°C, cycle and wash for 2 hours, and drain the washing oil. Add toluene at 20°C, circulate and wash for 2h, and then discharge the toluene. Finally, drying was carried out with nitrogen at 120°C.

Embodiment 2

[0034] Mix 1.2 tons of carbon microspheres and 4.5 tons of washing oil, heat to 120°C, and then stir for 2 hours to form a mother liquor. The mother liquor is filled with the decanting body (1), and nitrogen gas (0.5MPa) is introduced for pressure filtration, and the liquid is discharged after filtering for 3 hours. Add washing oil at 130°C, circulate and wash for 3 hours, and drain the washing oil. Add toluene at 30°C, circulate and wash for 3h, and then discharge the toluene. Finally, it is dried with steam at 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com