A kind of preparation method and application of thermosetting epoxy resin shape memory polymer

A memory polymer and epoxy resin technology, applied in the field of intelligent polymer materials, can solve the problem of insufficient toughness of epoxy resin, and achieve the effects of good reaction, high efficiency and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

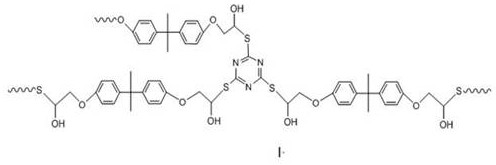

Method used

Image

Examples

Embodiment 1

[0045] Mix 6g of epoxy resin E51, 1g of thiocyanuric acid and 0.02g of catalyst 2-methylimidazole, and stir for 30min under vacuum. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24h of natural cooling, a thermosetting epoxy resin was prepared. Resin shape memory polymer material.

[0046]The prepared thermosetting epoxy resin shape memory polymer material sample is deformed at a temperature of 51°C + 10°C, and then cooled to 25°C, the shape can be fixed into a temporary shape, and then placed at 51°C, the sample can be deformed again Return to the original shape.

Embodiment 2

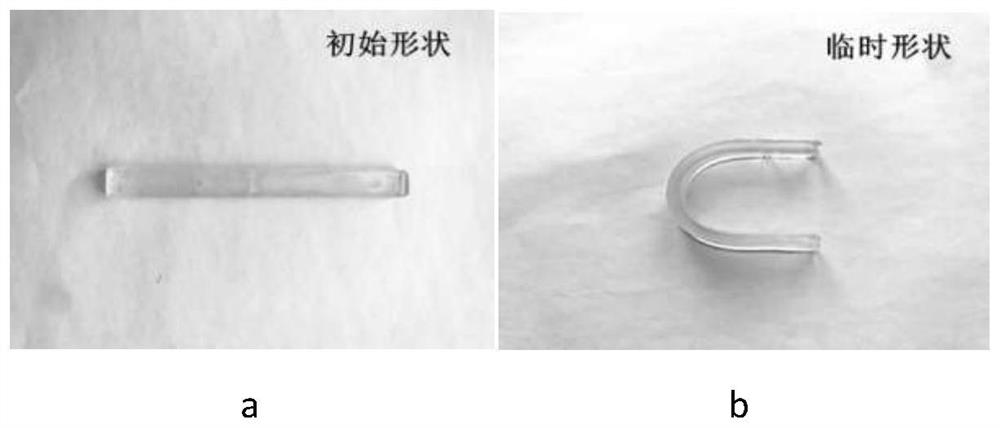

[0048] Mix 6g of epoxy resin E51, 2g of thiocyanuric acid and 0.02g of catalyst 2-methylimidazole, and stir for 30min under vacuum. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24h of natural cooling, a thermosetting epoxy resin was prepared. Resin shape memory polymer materials (such as figure 1 a).

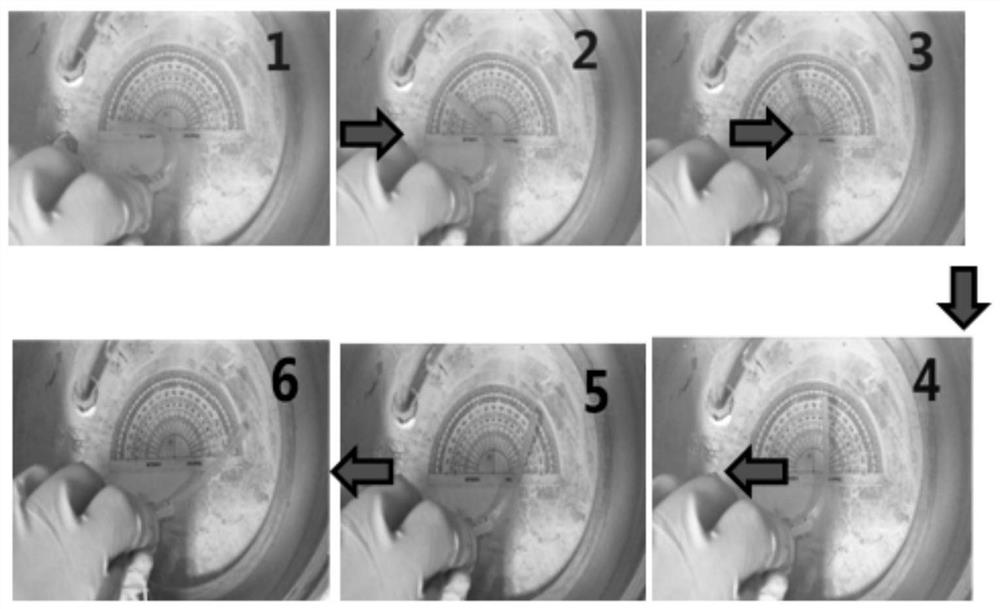

[0049] The prepared thermosetting epoxy resin shape memory polymer material sample is deformed at a temperature of 62°C+10°C, and then cooled to 25°C, the shape can be fixed into a temporary shape (such as figure 1 b), and then put it at 62°C and the sample can return to its original shape (such as figure 2 ).

Embodiment 3

[0051] Mix 6g of epoxy resin E51, 3g of thiocyanuric acid and 0.02g of catalyst 2-methylimidazole, and stir for 30min under vacuum. Pour the uniformly stirred mixture into a polytetrafluoroethylene mold, and place it under vacuum conditions, react at 80°C for 3h, at 120°C for 2h, and at 150°C for 1h, and after 24h of natural cooling, a thermosetting epoxy resin was prepared. Resin shape memory polymer material.

[0052] The prepared thermosetting epoxy resin shape memory polymer material sample is deformed at a temperature of 70°C + 10°C, and then cooled to 25°C, the shape can be fixed into a temporary shape, and then placed at 70°C, the sample can be deformed again Return to the original shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com